Preparation method of binderless spherical faujasite particles

A faujasite and binder-free technology, which is applied in the field of preparation of spherical zeolite particles, can solve problems such as the decline in adsorption capacity and mass transfer performance, and achieve the effects of good crushing strength, simple method, and high zeolite content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

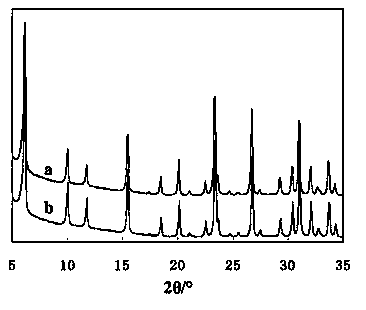

Image

Examples

example 1

[0041] Silica gel pellets are prepared according to the method of the present invention.

[0042] Take sodium silicate solution A (produced by Sinopec Catalyst Qilu Branch), which contains SiO 2 19.9% by mass, Na 2 O 6.1% by mass, density at 25°C is 1.253g / cm 3 .

[0043] Slowly add 7.14 kg of concentrated sulfuric acid with a concentration of 98% by mass into 42.84 kg of deionized water under stirring conditions, and then add 6.50 kg of ammonium sulfate, stir and dissolve evenly, and record it as solution B. H in solution B 2 SO 4 The concentration is 12.39% by mass, (NH 4 ) 2 SO 4 The concentration is 11.51% by mass, and the density at 25°C is 1.135g / cm 3 .

[0044] Cool the two solutions of A and B to 5°C, inject the A and B solutions into the nozzle at a certain flow rate through the metering pump and quickly mix them to form a sol, adjust the injection ratio of the A and B solutions, and control the pH value of the sol to 6.7, The silica content in this was 11...

example 2

[0046] According to the method of the present invention, X zeolite particles are prepared by in-situ crystallization of silica gel beads.

[0047] (1) Preparation of directing agent

[0048] In a 500 ml beaker, add 27.6 g of sodium metaaluminate solution (produced by Sinopec Catalyst Qilu Branch, containing Al 2 o 3 10.6% by mass, Na 2 O 12.5% by mass), 56.8 grams of deionized water and 29.9 grams of sodium hydroxide (produced by Beijing Chemical Plant, with a purity of 99% by mass), stirred to completely dissolve the solid sodium hydroxide, and added 155.8 grams of sodium silicate solution (Sinopec catalyst Qilu Branch production, including SiO 2 19.9% by mass, Na 2 O 6.1% by mass). The molar composition of the mixture in terms of oxides is 20.2Na 2 O:Al 2 o 3 : 18SiO2 2 : 387H 2 O, stirred at 400 rpm until uniformly mixed, and aged at 25°C for 16 hours to prepare the directing agent.

[0049] (2) Preparation of X zeolite particles

[0050] Add 403.9 grams of ...

example 3

[0053] Prepare X zeolite particle by the method for example 2, difference is (2) in step, add 767.3 gram sodium metaaluminate solutions, 596.5 gram deionized water, 29.1 gram sodium hydroxide, stir and make it fully mix, in synthesis kettle Add 142.9 grams of the silica gel pellets prepared in Example 1 at a stirring speed of 150 rpm, age under stirring at 40°C for 4 hours, then add 30.7 grams of directing agent, and the molar composition of the total mixture in terms of oxides is 2.4Na 2 O:Al 2 o 3 ︰3.0SiO2 2 : 105H 2 O, then crystallized, washed, filtered, and dried to obtain the X zeolite granular product. The detailed test results of its physical and chemical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com