Prediction method of crushing strength of coke for coal blending coking

A technology of crushing strength and prediction method, applied in the direction of fuel oil testing, material inspection products, etc., can solve the problems of differences in coke strength changes, lack of scientificity, and large test workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

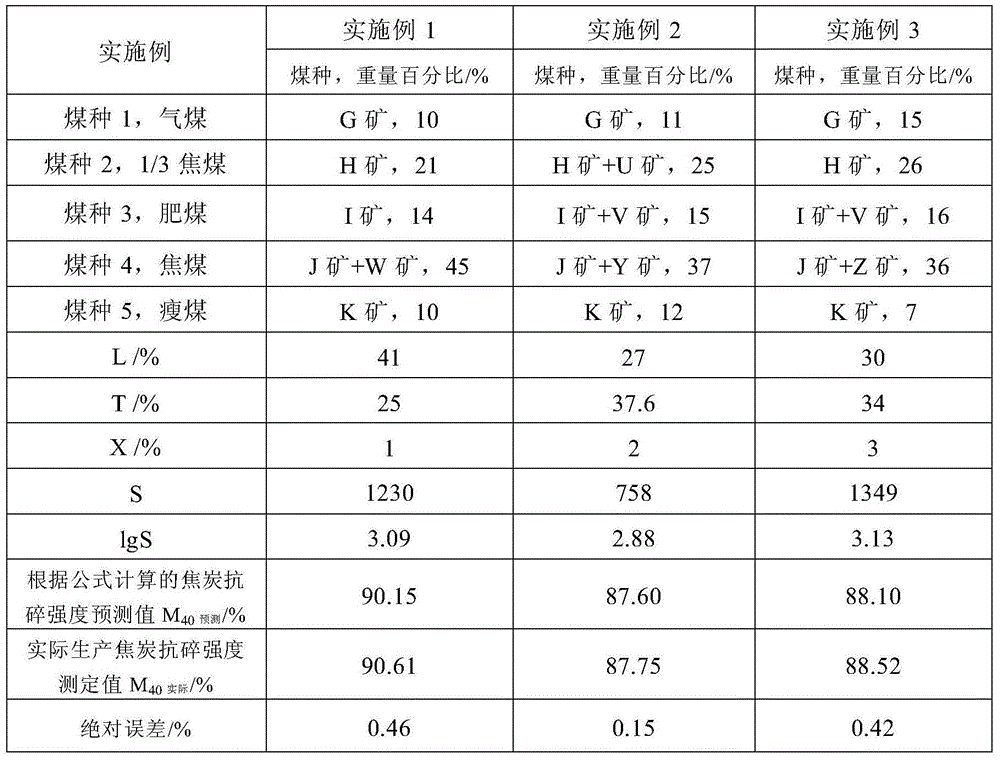

[0016] The present invention will be described in further detail below in conjunction with specific embodiments.

[0017] Method of the present invention comprises the steps:

[0018] 1) Determine the coke-forming optical structure of each single coal used for coking, calculate the sum L of the coarse-grained mosaic, medium-grained mosaic, and incomplete fiber components in the blended coal, and calculate the isotropic The sum T of the content of the component and the mosaic component of fine grains, and the content X of the fiber component.

[0019] 2) Determining the Giraffel fluidity of the blended coal to obtain the Giraffel plastic flow area S of the blended coal in the temperature range of 450°C to 500°C, the unit is DD;

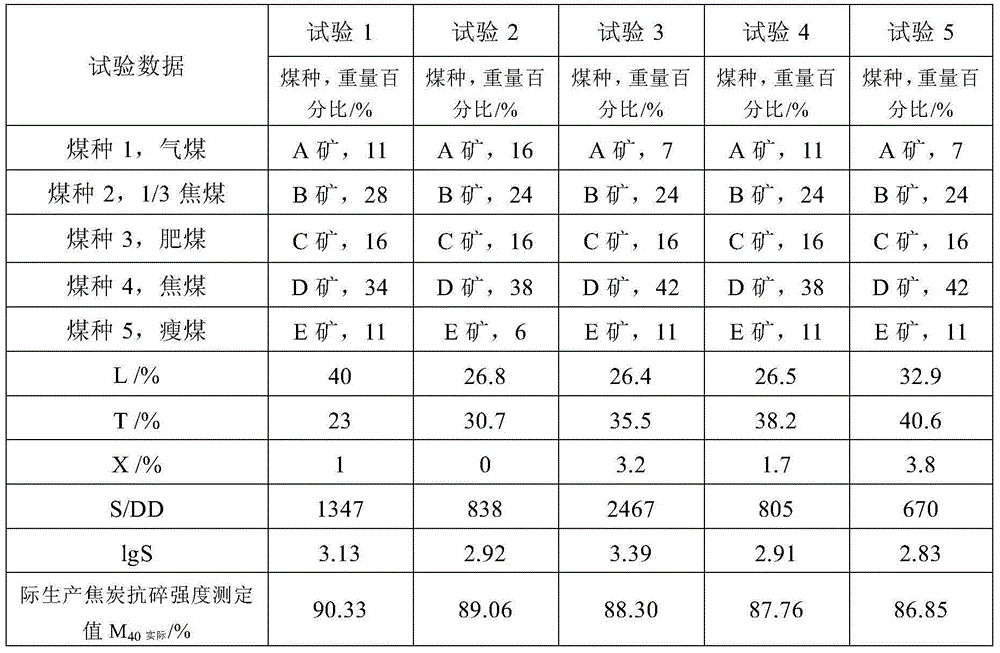

[0020] 3) Set M 40 =A+B*L+C*T+E*X+F*lgS, where M 40 Represents the predicted value of coke crushing strength, in %; A, B, C, E, F are constants, calculated by substituting 5 groups of coal blending coking tests or actual production data into this fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com