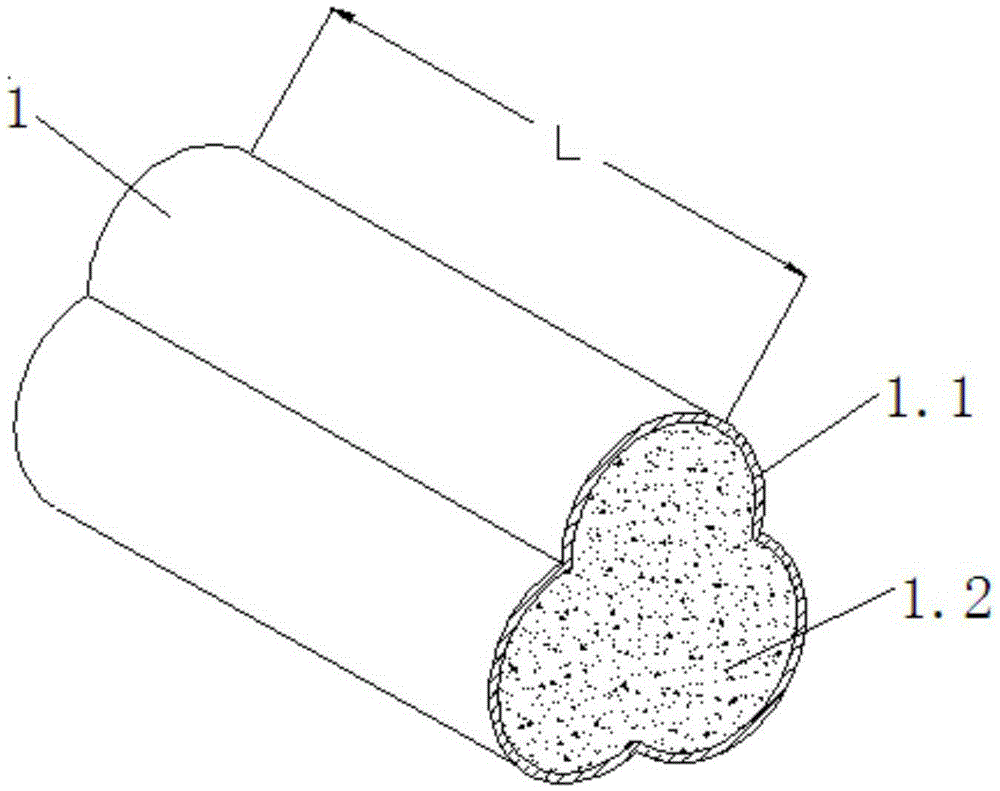

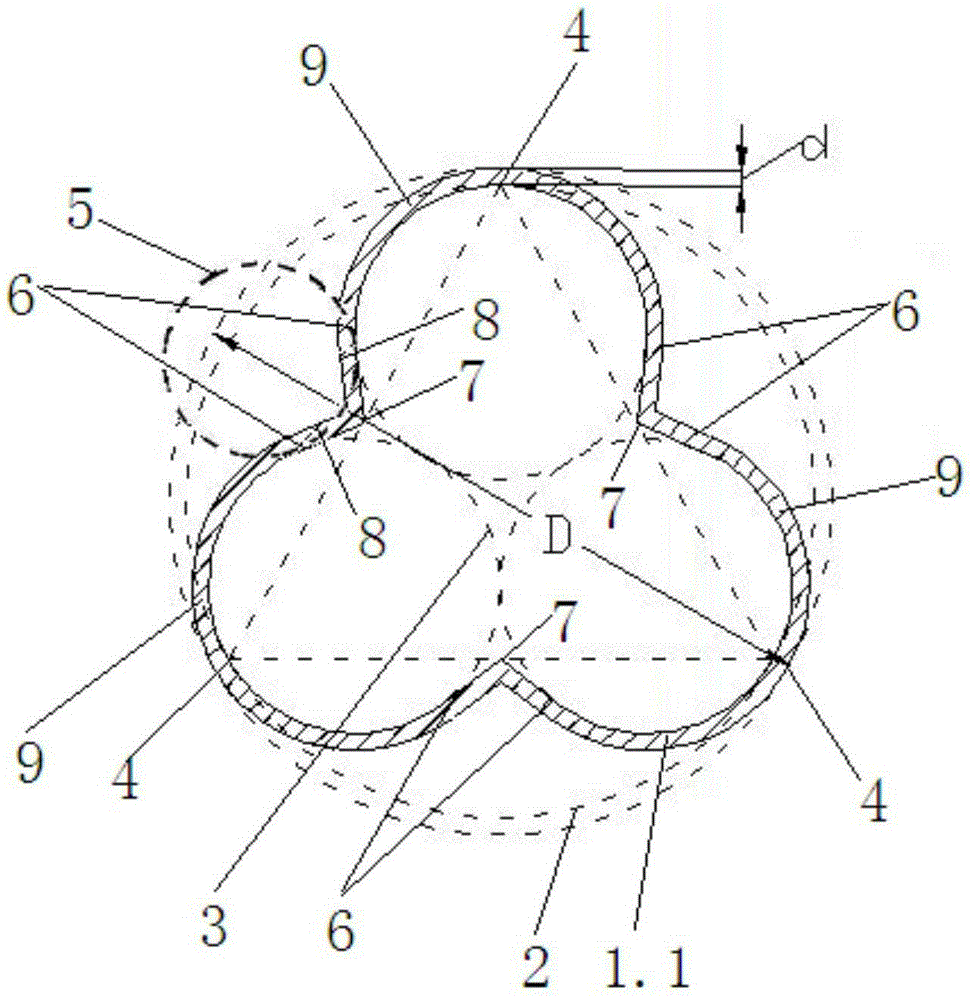

Inner core type cloverleaf-pattern catalyst carrier and preparation method and application thereof

A catalyst carrier, clover-shaped technology, used in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unfavorable industrial application, low crush resistance, short service life, etc., and achieve low methane selection. properties, improve crushing strength, and improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

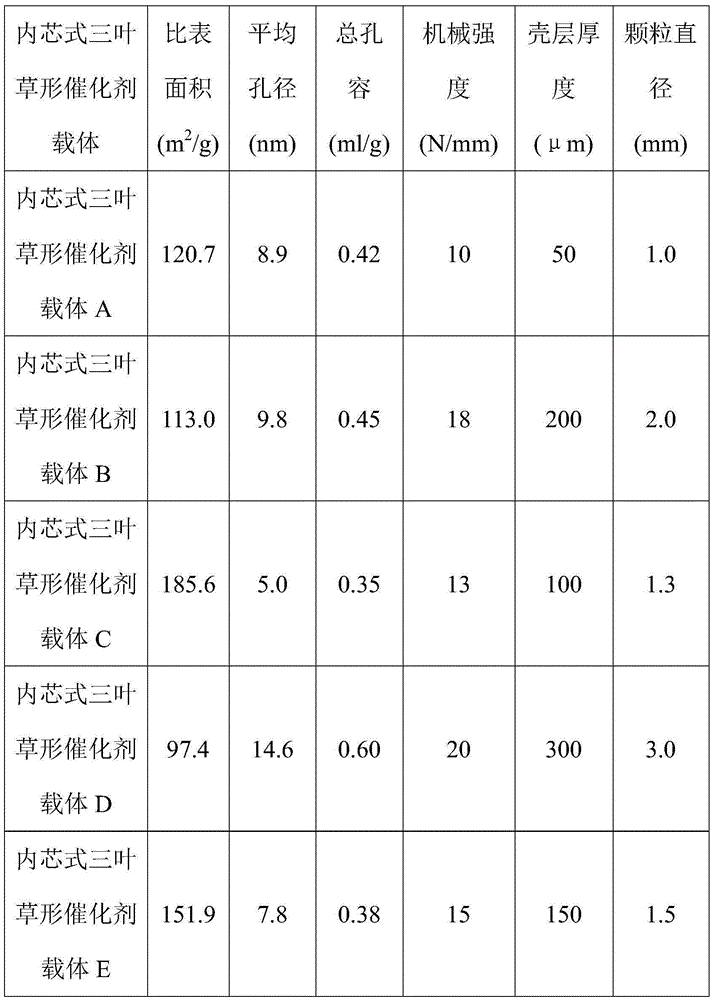

Embodiment 1

[0037] 1) Weigh 220g of pseudo-boehmite and put it into a clean beaker for subsequent use, wherein the physical parameter of pseudo-boehmite is a specific surface area of 237m 2 / g, average pore diameter 10.1nm, total pore volume 0.92cm 3 / g; Weigh 132g of deionized water (water-powder ratio 0.6), add extrusion aid 6.6g squash powder (accounting for 3.0% of raw material powder quality), add peptizer 6.6g nitric acid, be made into solution I; Pour the diaspore into the kneader, then pour into the solution Ⅰ, and knead for 30 minutes to obtain the material Ⅰ;

[0038] 2) Weigh 220g with a specific surface area of 0.1m 2 / g of α-Al 2 o 3 Put it in a clean beaker for later use; weigh 132g of deionized water (water-to-powder ratio 0.6), add 6.6g of squash aid (accounting for 3.0% of the mass of the raw material powder), add peptizer 6.6g of nitric acid, and make solution II , and then the α-Al 2 o 3 Pour into the kneader, then pour into solution II, and knead for 30 minut...

Embodiment 2

[0044] 1) Weigh 220g of pseudo-boehmite and put it into a clean beaker for subsequent use, wherein the physical parameter of pseudo-boehmite is a specific surface area of 205m 2 / g, average pore diameter 11.5nm, total pore volume 1.00cm 3 / g; Weigh 154g deionized water (water-powder ratio 0.7), add extrusion aid 17.6g citric acid (accounting for 8.0% of raw material powder quality), add peptizer 11.0g acetic acid, be made into solution Ⅰ, then the pseudo thin water Pour the bauxite into the kneader, then pour into the solution Ⅰ, and knead for 10 minutes to obtain the material Ⅰ;

[0045] 2) Weigh 220g with a specific surface area of 0.1m 2 / g of α-Al 2 o 3 Put it into a clean beaker for subsequent use; weigh 154g deionized water (water-to-powder ratio 0.7), add extrusion aid 17.6g citric acid (accounting for 8.0% of raw material powder mass), add peptizing agent 11.0g acetic acid, be made into solution II, Then α-Al 2 o 3 Pour into a kneader, then pour into solution...

Embodiment 3

[0051] 1) Weigh 220g of pseudo-boehmite and put it into a clean beaker for subsequent use, wherein the physical parameter of pseudo-boehmite is a specific surface area of 320m 2 / g, average pore diameter 5.1nm, total pore volume 0.60cm 3 / g; Weigh 110g deionized water (water-powder ratio 0.5), add extrusion aid 11.0g tartaric acid (accounting for 5.0% of raw material powder quality), add peptizer 4.4g formic acid, be made into solution Ⅰ, then pseudo-both aluminum Pour the stone into the kneader, then pour into the solution Ⅰ, and knead for 1 hour to obtain the material Ⅰ;

[0052] 2) Weigh 220g with a specific surface area of 0.1m 2 / g of α-Al 2 o 3 Put into clean beaker for subsequent use; Take by weighing 110g deionized water (water-powder ratio 0.5), add extrusion aid 11.0g tartaric acid (accounting for 5.0% of raw material powder quality), add peptizer 4.4g formic acid, be made into solution II, then α-Al 2 o 3 Pour into a kneader, then pour into solution II, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com