Preparation method for Silicate-1 molecular sieve catalyst, catalyst and method for preparing caprolactam

A molecular sieve and catalyst technology, which is used in the preparation of Silicate-1 molecular sieve catalyst and the field of catalyst and caprolactam preparation, to achieve the effects of improving conversion rate, fine particle size and good crushing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

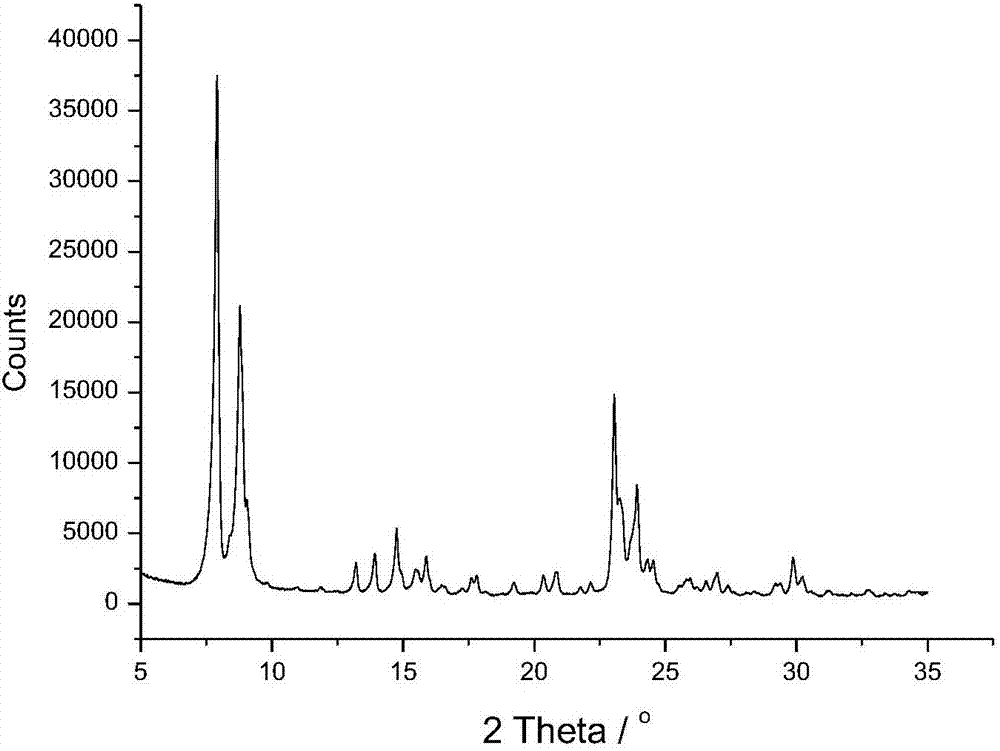

[0053] The first aspect of the present invention: provide a kind of preparation method of the Silicate-1 molecular sieve catalyst containing trace metal ion, this method comprises: a, silicon source, metal ion source, organic templating agent and water are mixed, obtain colloidal mixture, wherein, In molar ratio, SiO in the colloidal mixture 2 : organic templating agent: H 2 O=1: (0.05-0.50): (5-100), preferably SiO 2 : organic templating agent: H 2 O=1: (0.15-0.25): (10-50); the mass ratio of silicon oxide to metal ions is (5000-200000): 1, preferably, the mass ratio of silicon oxide to metal ions is (10000-100000) : 1; b, carrying out hydrothermal crystallization of the colloidal mixture obtained in step a, to obtain a crystallized product; c, washing and separating the crystallized product obtained in step b, to obtain a product containing trace metal ions Silicate-1 molecular sieve; d, the Silicate-1 molecular sieve containing trace metal ions obtained in step c is subj...

Embodiment 1

[0080] This example is used to illustrate the preparation method of the Silicate-1 molecular sieve catalyst containing trace metal ions provided by the present invention.

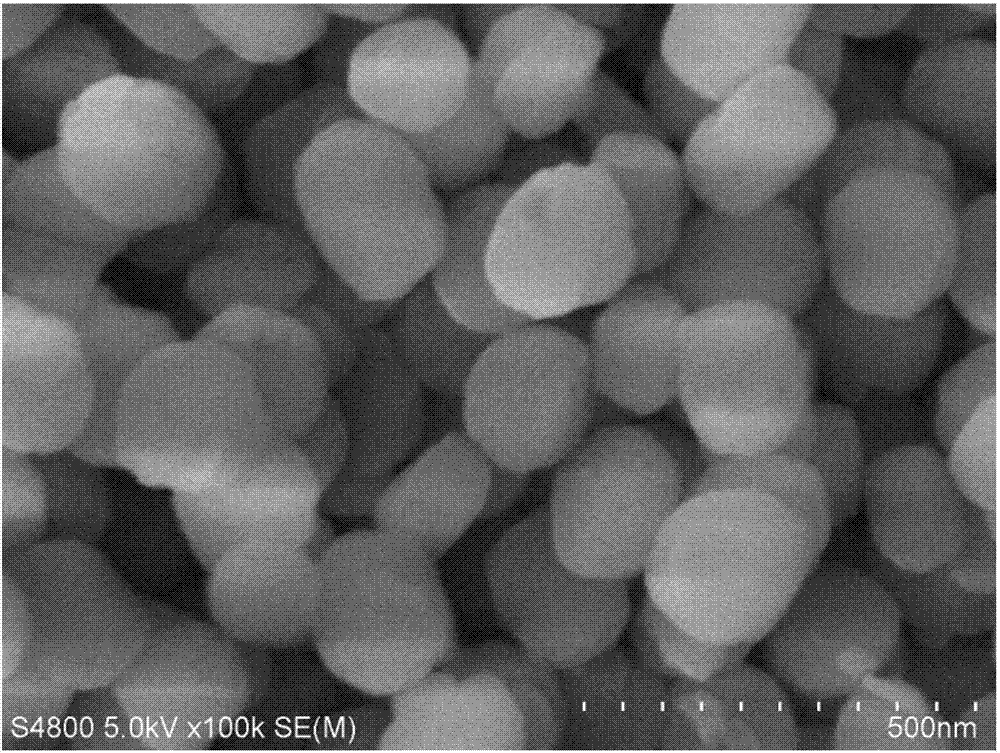

[0081] With 208 grams of ethyl orthosilicate, 180 grams of 22.5% by weight of tetrapropylammonium hydroxide (abbreviated as TPAOH), 0.0281 grams of Fe (NO 3 ) 3 9H 2 O and 220 grams of water were mixed and stirred at room temperature for 3 hours to form a colloidal mixture with a molar ratio of SiO 2 :TPAOH:H 2 O=1:0.2:20, SiO 2 with Fe 3+ The mass ratio of the above mixture is 15347:1, and the above mixture is moved into a 1000 ml stainless steel reactor lined with polytetrafluoroethylene, crystallized at 100°C for 3 days, washed, filtered, dried at 120°C for 24 hours, and roasted at 550°C for 6 hours. The Silicate-1 molecular sieve prepared in this example was obtained.

[0082] The iron ion content of the Silicate-1 molecular sieve product prepared by this embodiment is 64ppm, and the BET specific ...

Embodiment 2

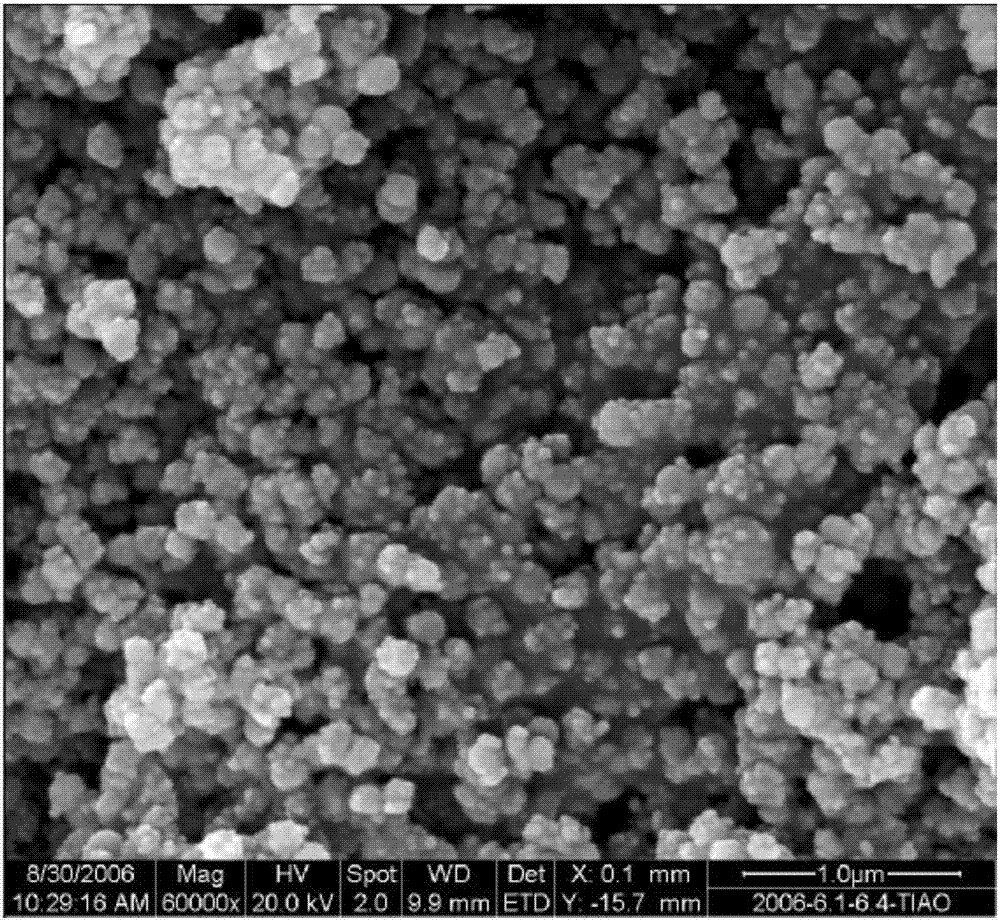

[0088] This example is used to illustrate the preparation method of the Silicate-1 molecular sieve catalyst containing trace metal ions provided by the present invention.

[0089] With 208 grams of ethyl orthosilicate, 180 grams of 22.5% by weight of tetrapropylammonium hydroxide (abbreviated as TPAOH), 0.118 grams of Al (NO 3 ) 3 9H 2 O and 220 grams of water were mixed and stirred at room temperature for 5 hours to form a colloidal mixture with a molar ratio of SiO 2 :TPAOH:H 2 O=1:0.2:20, SiO 2 with Al 3+ The mass ratio of the above mixture is 7067:1. The above mixture is transferred into a 1000 ml stainless steel reactor lined with polytetrafluoroethylene, crystallized at 100°C for 3 days, washed, filtered, dried at 120°C for 24 hours, and roasted at 550°C for 6 hours. The Silicate-1 molecular sieve prepared in this example was obtained.

[0090] The aluminum ion content of the Silicate-1 molecular sieve product prepared in this embodiment is 140ppm, and the BET spec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com