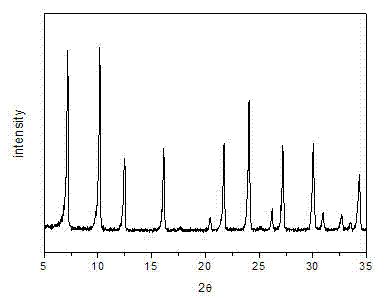

Composite method of mesoporous A type molecular sieve

A synthesis method and molecular sieve technology are applied in the directions of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., and can solve the problems of low mass transfer rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

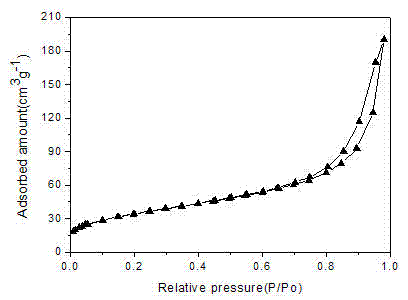

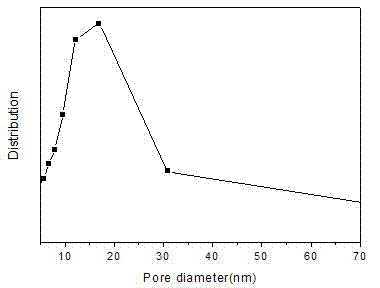

Embodiment 1

[0025] 1 g of multi-walled carbon nanotubes was impregnated with 20 ml of KH-560 solution with a mass fraction of 5% for 1 hour, filtered with suction, and dried at 100°C for 10 minutes to obtain treated multi-walled carbon nanotubes M1; 0.75 g of Na 2 SiO 3 9H 2 O, 3ml of water, 0.1g of M1 and 0.1g of KH-660 were stirred at 70°C for 3 hours, and the resulting mixture was added to 3ml of sodium metaaluminate solution with a mass fraction of 11%, and transferred to polytetrafluoroethylene after stirring for 0.5 hours In a lined reactor, crystallize at 100°C for 15 hours, wash with suction, dry at 100°C, and then calcinate at 550°C for 15 hours to obtain the final product. The pore structure parameters of the obtained samples are listed in Table 1.

Embodiment 2

[0027] 1 g of multi-walled carbon nanotubes was impregnated with 20 ml of KH-560 solution with a mass fraction of 5% for 1 hour, filtered with suction, and dried at 100°C for 10 minutes to obtain treated multi-walled carbon nanotubes M1; 0.75 g of Na 2 SiO 3 9H 2 O, 3ml of water, 0.3g of M1 and 0.3g of KH-660 were stirred at 70°C for 3 hours, and the resulting mixture was added to 3ml of sodium metaaluminate solution with a mass fraction of 11%, and transferred to polytetrafluoroethylene after stirring for 5 hours In a lined reactor, crystallize at 100°C for 15 hours, wash with suction, dry at 100°C, and then calcinate at 550°C for 15 hours to obtain the final product. The pore structure parameters of the obtained samples are listed in Table 1.

Embodiment 3

[0029] 1 g of multi-walled carbon nanotubes was stirred and impregnated with 20 ml of 5% KH-560 solution for 1 hour, filtered with suction and dried at 100°C for 10 min to obtain treated multi-walled carbon nanotubes M1; 0.46 g of TEOS (orthosilicon ethyl acetate), 3ml of water, 0.1g of M1 and 0.1g of KH-660 were stirred at 70°C for 3 hours, and the resulting mixture was added to 3ml of sodium aluminate solution with a mass fraction of 11%, stirred for 12 hours, and then transferred to polytetrafluoroethylene Crystallize at 100°C for 15 hours in a vinyl fluoride-lined reactor, wash with suction, dry at 100°C, and then calcinate at 550°C for 15 hours to obtain the final product. The pore structure parameters of the obtained product are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com