Preparation method of high performance permeation evaporation permeable membrane

A pervaporation and water-permeable membrane technology, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problem of difficult to control the direction of molecular sieve crystal growth, the surface of molecular sieve membrane is not uniform and complete, and the growth mechanism of molecular sieve crystal is complex, etc. problems, to achieve the effect of excellent separation performance, increased operational flexibility, and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

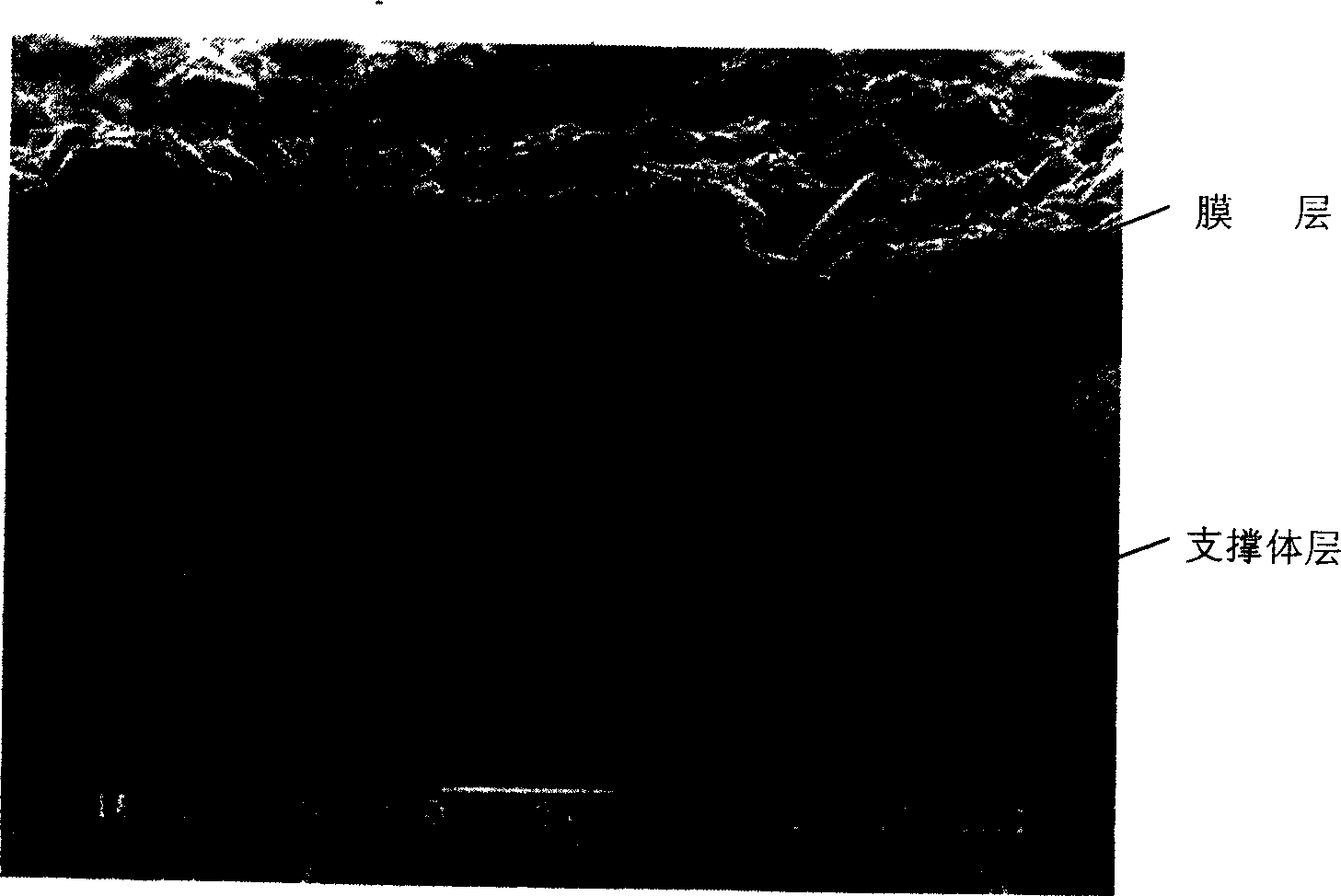

[0027] The support body is a porous mullite tube prepared by the Membrane Department of Nanjing University of Technology, and the composition of mullite is 75wt%Al 2 o 3 , 25wt% SiO 2 . According to 6.25Na 2 O: 2.5Al 2 o 3 : 5SiO 2 : 300H 2 The molar ratio of O is the formula, calculate silicon source, aluminum source and NaOH, H 2 The required amount of O was weighed separately with an electronic balance. The silicon solution and the aluminum solution are mixed and stirred to form a gel, and then poured into a reactor made of polymer material.

[0028] Put the support body pre-coated with NaA molecular sieve seed crystals into the reactor that has been filled with the mixed gel, and seal it. Put the reactor horizontally into the heating device for reaction, and ensure that the support is completely immersed in the gel. The hydrothermal synthesis temperature is 100°C, and the synthesis time is 2.5 hours.

[0029] After the synthesis is completed, the synthesized memb...

Embodiment 2

[0035]The synthesis reaction and performance test were carried out according to the steps of Example 1. The difference is that the synthesis time is 3 hours, and the pervaporation performance is shown in Table 1.

Embodiment 3

[0037] The synthesis reaction and performance test were carried out according to the steps of Example 1, except that the synthesis time was 3.5 hours, and the pervaporation performance was shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com