Method for synthesizing monolithic 4A molecular sieve by dry glue process

A monolithic, molecular sieve technology, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of waste of raw materials, pollution, complicated procedures of 4A molecular sieve, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

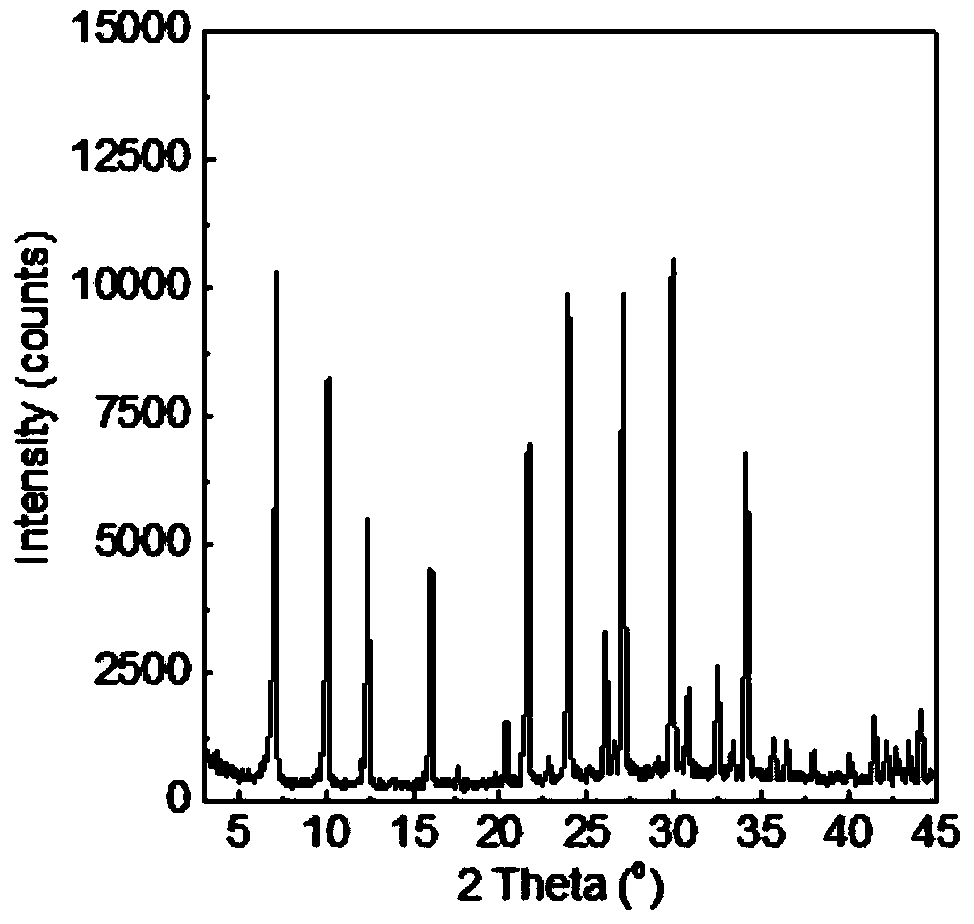

[0026] Dissolve 2.8g NaOH in 6g of water in a plastic beaker, take 10g of metakaolin and add it to the above solution under stirring conditions, mix the metakaolin and sodium hydroxide solution evenly to form a dry gel, then extrude into strips, at room temperature After aging for 4 hours, put it into a polytetrafluoroethylene crystallization kettle with a water jacket interlayer, add 4g of water to the bottom of the interlayer of the crystallization kettle, and crystallize at 100°C for 5 hours to obtain a molecular sieve. Figure analysis, the molecular sieve is 4A molecular sieve, such as figure 1 as shown, figure 2 It is the photo of the molecular sieve of the present embodiment 4A.

Embodiment 2

[0028] Dissolve 3g NaOH in 6g water in a plastic beaker, take 10g metakaolin and add it to the above solution under stirring conditions, mix metakaolin and sodium hydroxide solution evenly to form a dry gel, extrude it into a honeycomb shape, and age at room temperature After 4 hours of melting, put it into a polytetrafluoroethylene crystallization kettle with a water jacket interlayer, add 3g of water to the bottom of the crystallization kettle interlayer, and crystallize at 95°C for 5 hours. Analyze by XRD spectrum , to obtain 4A molecular sieve.

Embodiment 3

[0030] Dissolve 3.5g NaOH in 6g water in a plastic beaker, take 10g metakaolin and add it to the above solution under stirring conditions, mix metakaolin and sodium hydroxide solution evenly to form a dry gel, then the water column becomes spherical, and age at room temperature After 4 hours, put it into a polytetrafluoroethylene crystallization kettle with a water jacket interlayer, add 3g of water at the bottom of the interlayer of the crystallization kettle, and crystallize at 95°C for 5 hours. After XRD spectrum analysis, Get 4A molecular sieve, image 3 It is the photo of the molecular sieve of the present embodiment 4A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com