Method for preparing NaA molecular sieve from geopolymer

A geopolymer, molecular sieve technology, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve problems such as difficulty in molding NaA molecular sieve products according to application requirements, product granularity, etc. A wide range of raw materials and the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

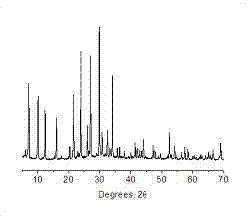

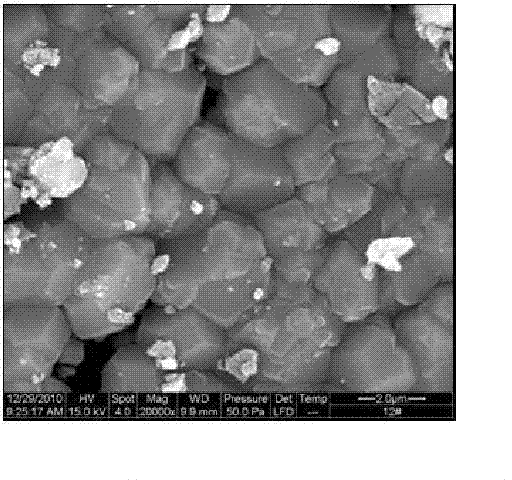

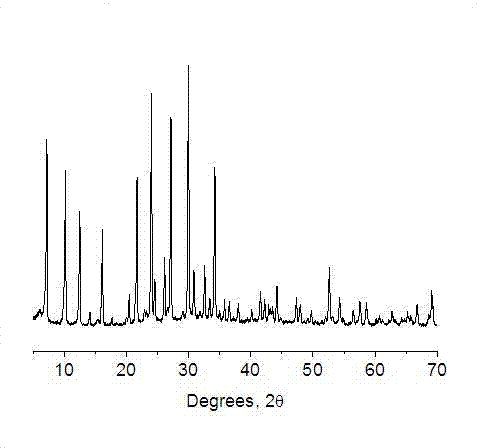

Image

Examples

Embodiment 1

[0031] 1.Al 2 o 3 -2SiO2 2 Powder preparation:

[0032] Aluminum chloride (AR) and absolute ethanol were mixed with a molar ratio of 1:4 and magnetically stirred for 12 hours to prepare aluminum sol for use. Stir for half an hour to prepare a silica sol for use. Add aluminum sol dropwise to the stirring silica sol to prepare a composite sol with a silicon-aluminum ratio of 1:1, continue stirring for 2 hours, put it in a constant temperature water bath at 70°C until a transparent and uniform gel appears, and age at room temperature for 36 hours , dried at 105°C for 12 hours, ground, and calcined at 800°C for 2 hours to obtain amorphous Al 2 o 3 -2SiO2 2 powder ready for use;

[0033] 2. Preparation of 10 mol / L NaOH solution:

[0034] Weigh 104.17g of solid NaOH (AR) with a mass fraction of 96%, put it into a plastic beaker, add 150ml of deionized water and stir until it is completely dissolved, transfer it to a 250ml volumetric flask after cooling, add deionized water...

Embodiment 2

[0037] 1.Al 2 o 3 -SiO 2 Powder preparation:

[0038] Aluminum nitrate (AR) and absolute ethanol were mixed with a molar ratio of 1:4 and magnetically stirred for 12 hours to prepare aluminum sol for use. Silica sol was prepared in half an hour for use. Add aluminum sol dropwise to the stirring silica sol to prepare a composite sol with a silicon-aluminum ratio of 1:2, continue stirring for 2 hours, put it in a constant temperature water bath at 70°C until a transparent and uniform gel appears, and age at room temperature for 36 hours , dried at 105°C for 12 hours, ground, and calcined at 800°C for 2 hours to obtain amorphous Al 2 o 3 -SiO 2 powder ready for use;

[0039] 2. Mole ratio SiO 2 / Al 2 o 3 =2, Na 2 O / Al 2 o 3 =1, weigh 45gAl 2 o 3 -SiO 2 The powder was mixed with 66.45g of water glass and stirred for 30 minutes. The solid content of the water glass used was 37.39%, and the modulus of the water glass was 0.9. Inject into a sheet mold, maintain at 6...

Embodiment 3

[0041] 1. Preparation of metakaolin:

[0042] The kaolin powder produced by Guangxi Beihai Yankuang Group with a fineness of more than 250 meshes and washed with water was calcined in the air at 800°C for 2 hours to obtain metakaolin. Al in metakaolin 2 o 3 :42.35%, SiO 2 : 56.91%, Fe 2 o 3 :0.74%;

[0043] 2. Preparation of boehmite:

[0044] AlCl 3 ·6H 2 O(AR) was prepared into a 5mol / L solution, and the aluminum chloride solution was stirred and hydrolyzed in a water bath at 70°C for 2 hours for later use. The analytically pure ammonia water and deionized water were prepared into an ammonia solution at a mass ratio of 1:1, and the Add 100 ml of the above-prepared aluminum chloride solution dropwise into 100 ml of the prepared ammonia solution, stir while dripping, control the pH of the system to 9-10, and obtain a precipitated product. The precipitate was aged for 24 hours, washed with water, and suction filtered to fully remove Cl- and NH4+ to obtain a filter cake,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com