Method for synthesizing zeolite by circulating fluidized-bed coal ash and bottom ash

A circulating fluidized bed and synthetic zeolite technology, applied in chemical instruments and methods, crystalline aluminosilicate zeolite, A-type crystalline aluminum silicate zeolite, etc., can solve the problem of poor ion exchange performance, complex zeolite conditions, and small specific surface area and other problems, to achieve the effect of improving production capacity ratio, high crystal purity, and high cation exchange capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

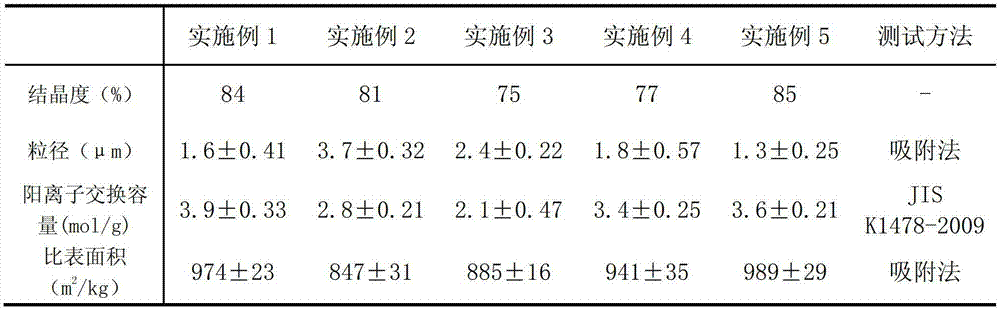

Examples

Embodiment 1

[0038] The circulating fluidized bed fly ash and bottom ash from A power plant are selected, the fly ash is screened and decarbonized by a sieving machine, the bottom ash is ground by a ball mill, and then mixed evenly in a dry mixer according to a certain proportion. SiO in the mixture 2 +Al 2 o 3 >80w%, SiO 2 / Al 2 o 3 =1.2 (mass ratio), according to the ratio of liquid to solid 5:1 (weight ratio) to OH - The lye with an ion concentration of 3.2mol / L is mixed. Stir at a temperature of 95° C. at a speed of 50 to 70 r / min, and react for 1 hour in a normal-pressure reaction system. Then continue to stir at a speed of 20-40r / min, and react for 4 hours in an open system at a temperature of 95°C. Dehydration and filtration, repeated washing until pH=9 of the washing solution, collecting solid phase components, drying at 85°C for 3 hours to obtain the A-type zeolite product. The lye is prepared with NaOH and KOH in a molar ratio of 2:1.

Embodiment 2

[0040] The circulating fluidized bed fly ash and bottom ash from A power plant are selected, the fly ash is screened and decarbonized by a sieving machine, the bottom ash is ground by a ball mill, and then mixed evenly in a dry mixer according to a certain proportion. SiO in the mixture 2 +Al 2 o 3 >70w%, SiO 2 / Al 2 o 3 =1.4 (mass ratio), mix liquid to solid 9:1 (weight ratio) with 2.5mol / L NaOH solution. At a temperature of 100°C, stir at a speed of 59-70 r / min, and react in an open system for 2 hours. Then continue to stir at a speed of 20-40r / min, and react in an open system for 6h at a temperature of 100°C. Dehydration and filtration, repeated washing until pH=10 of the washing solution, collecting solid phase components, drying at 100°C for 5 hours to obtain the X-type zeolite product.

Embodiment 3

[0042] The circulating fluidized bed fly ash and bottom ash of B power plant are selected, and the fly ash is screened and decarbonized by a sieving machine, and the bottom ash is ground by a ball mill, and then mixed evenly in a dry mixer according to a certain proportion. SiO in the mixture 2 +Al 2 o 3 >70w%, SiO 2 / Al 2 o 3 =1.7 (mass ratio), according to the ratio of liquid to solid 6:1 (weight ratio), mix with 2.8mol / L NaOH solution. At a temperature of 98°C, stir at a speed of 50-70r / min, and react in an open system for 1.5h. Then continue to stir at a speed of 20-40r / min, and react for 5 hours in an open system at a temperature of 98°C. Dehydration and filtration, repeated washing until pH=10 of the washing solution, collecting solid phase components, drying at 90°C for 4 hours to obtain the P-type zeolite product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com