Method for preparing molecular sieve

A technology of molecular sieve and gel, which is applied in the direction of molecular sieve and alkali-exchange phosphate, molecular sieve and alkali-exchange compound, molecular sieve characteristic silicoaluminophosphate, etc., to achieve the effect of shortening the crystallization time and improving the relative crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

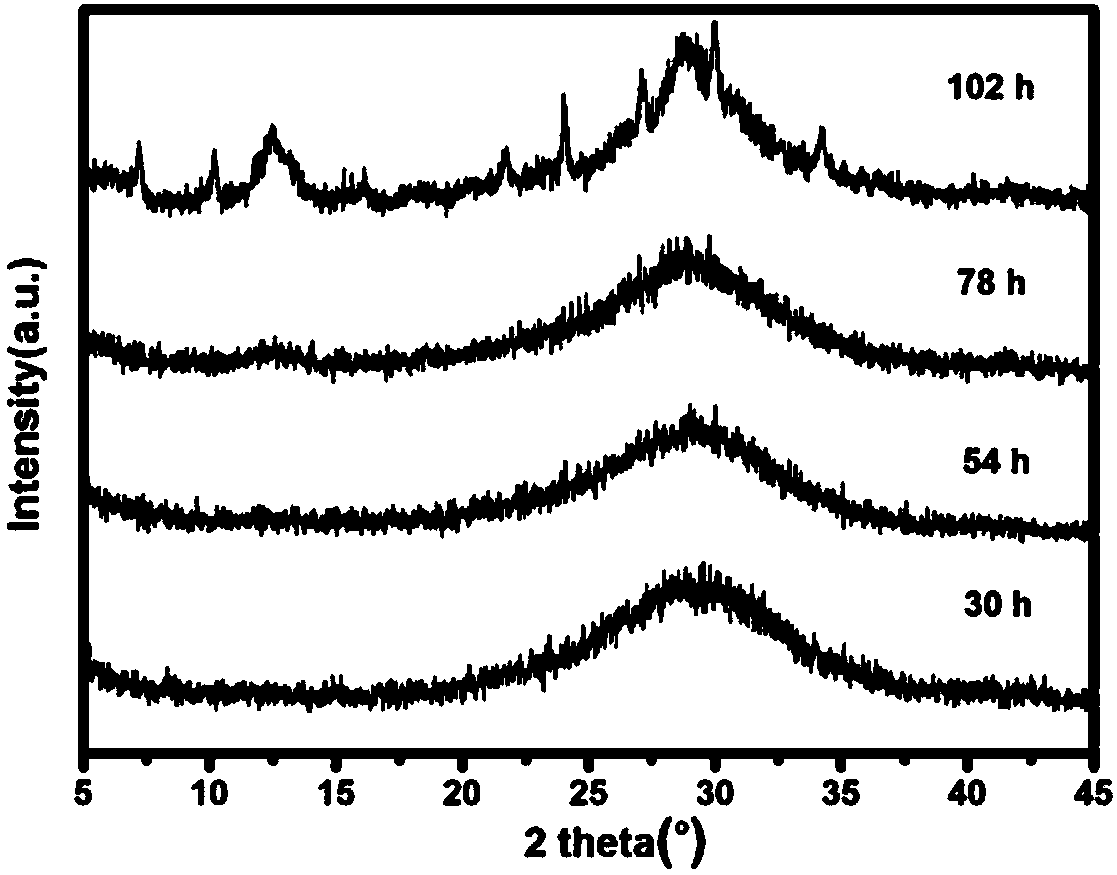

[0027] 221.01 g of Na 2 SiO 3 9H 2 O is dissolved in 361.8 grams of water to prepare a clear sodium silicate aqueous solution (material A), and 90.45 grams of NaAlO 2 and 170.05 grams of NaOH were dissolved in 361.8 grams of water to obtain material B. Add material B to material A under stirring, and after stirring evenly, put the obtained A molecular sieve gel into a plugged quartz tube, crystallize at 20°C for 30, 54, 78, 102 hours, and the obtained product is pumped Obtain A molecular sieve after filtering, washing, drying and roasting, and its XRD pattern is shown in figure 1 .

Embodiment 5-11

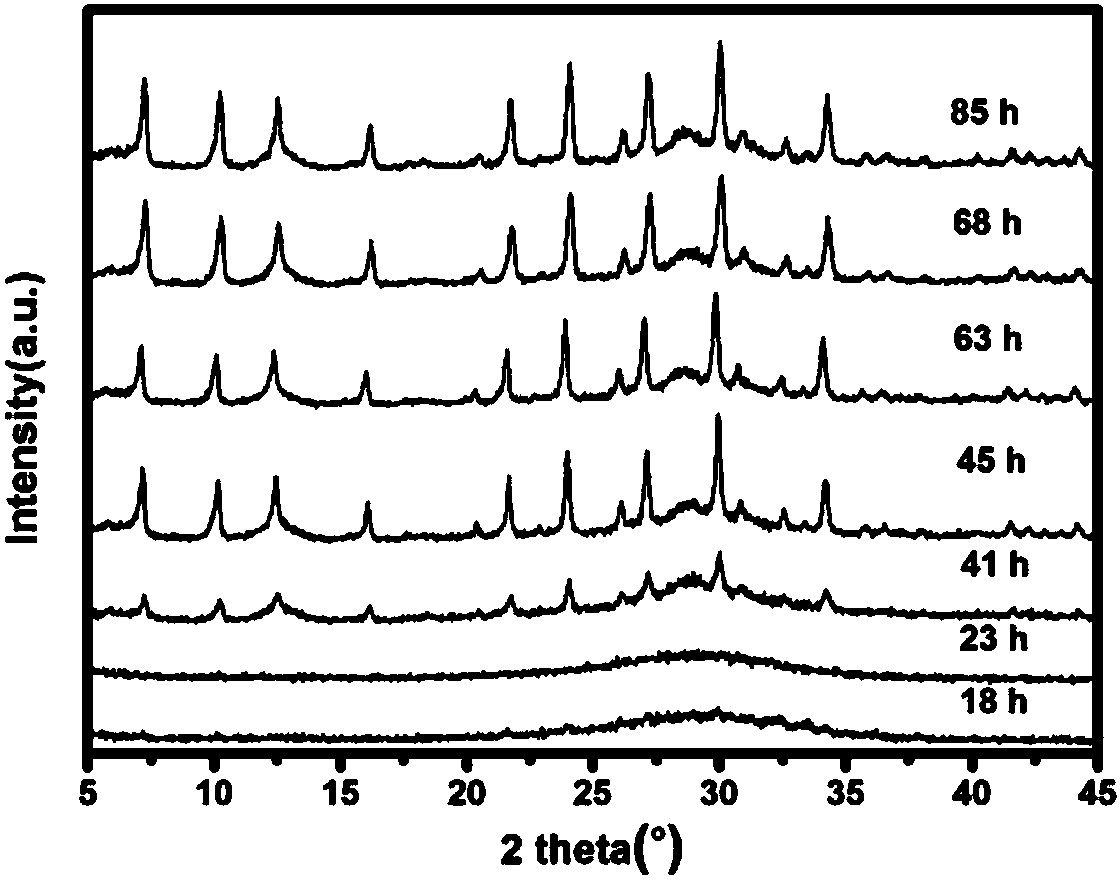

[0029] In Example 1, the obtained A molecular sieve gel was packed into a plugged quartz tube to 60 Co is the ray source, and at a radiation dose rate of 9 kGy (kilogray) / day and 20 ° C, the crystallization is 18, 23, 41, 45, 63, 68 and 85 hours, and the rest of the conditions are unchanged. XRD spectrum see figure 2 ;

Embodiment 12-17

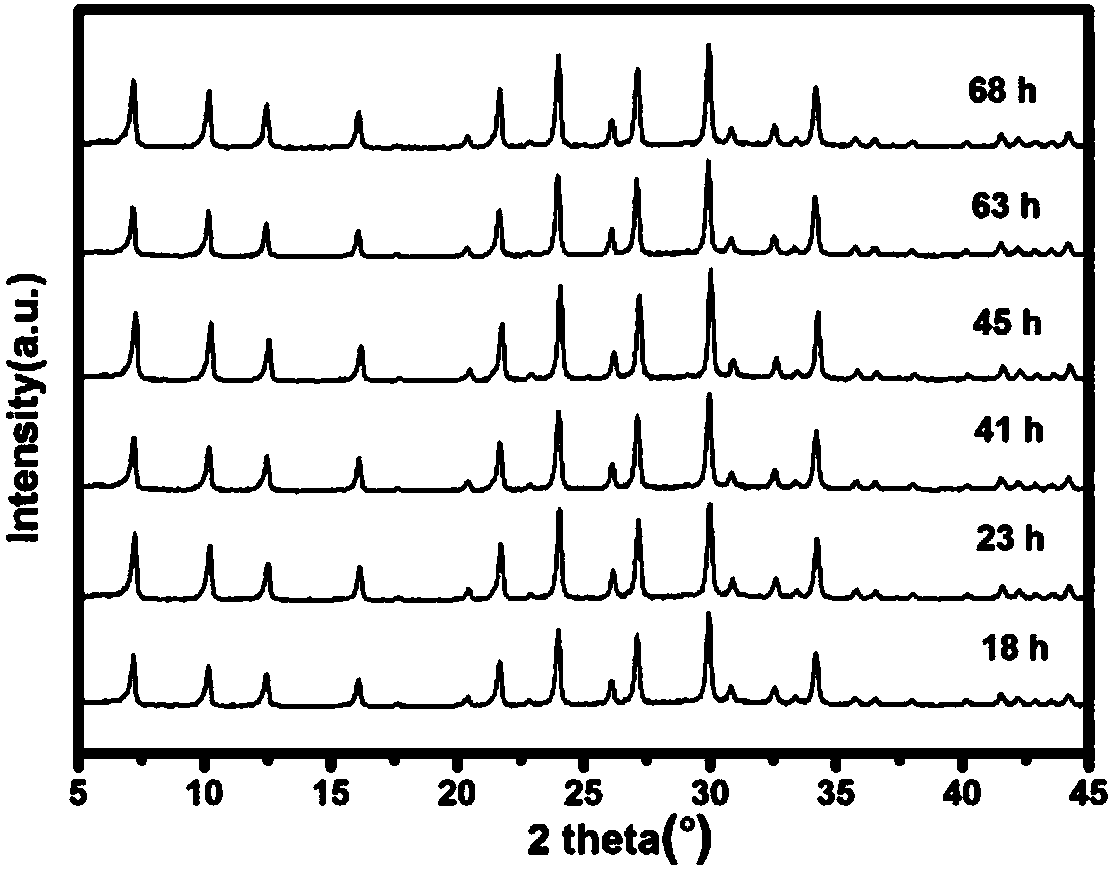

[0031] In Example 1, the obtained A molecular sieve gel was packed into a plugged quartz tube to 60 Co is the ray source, crystallized at 39kGy (kilogray) / day and 20°C for 18, 41, 45, 63, 68 and 85 hours, and the rest of the conditions remained unchanged. The XRD spectrum pattern of the obtained sample is shown in image 3 , the SEM image of the sample obtained after irradiation for 63 hours is shown in Figure 4 ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com