Production method of 4-A molecular sieve

A production method and molecular sieve technology, which are applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of reduced production efficiency, long reaction time, difficulty in filtering and washing, etc., and save chemical raw materials and energy. consumption, improving utilization and synthesis rate, and the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

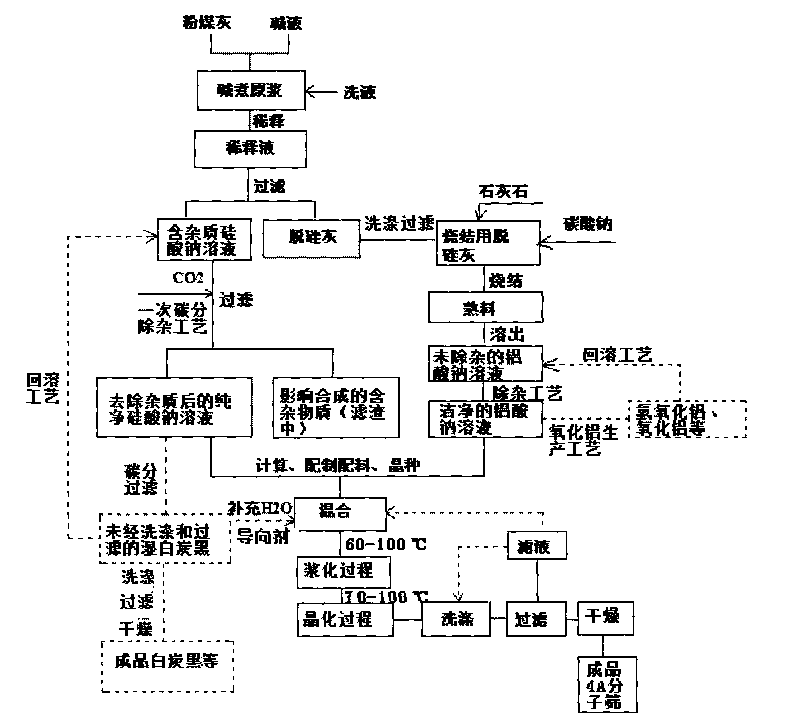

Image

Examples

Embodiment 1

[0046] Add 100L of 96.8g / L sodium aluminate solution that has been removed of impurities during the production of fly ash, raise the temperature of the solution to 75°C, and then add 100L of 108g / L sodium silicate solution that has been removed by carbon separation once to continuously Add it into the reaction vessel, and stir rapidly at 75°C for 15 minutes to make the materials evenly mixed, and the macroscopic performance is a uniform milky white emulsion. The molar ratios of the ingredients in this embodiment are respectively SiO 2 :Al 2 o 3 = 1.5, Na 2 O: SiO 2 =1.67,H 2 O:Na 2 O=75.3; put another 1L beaker, put the appropriate amount of Al 2 o 3 Sodium aluminate solution with a concentration of 30g / L and SiO 2 The sodium silicate solution with a concentration of 150g / L is mixed, and a certain amount of sodium hydroxide is added after mixing to make the final mixed solution Na 2 O: SiO 2 5, the mixed liquid is used as a guiding agent, add it to the above milky whi...

Embodiment 2

[0048] Put 100L of 120g / L sodium aluminate solution that has been removed from the fly ash production process into a reaction vessel, raise the temperature of the solution to 75°C, add 34.2kg of industrial sodium hydroxide to fully dissolve, and then put the Add 34.2kg of industrial sodium hydroxide to 100L of the impurity-removed 223.14g / L sodium silicate solution to fully dissolve, then continuously add to the reaction vessel, and stir rapidly at 80°C for 10 minutes to mix the materials evenly and macroscopically Show as uniform milky white emulsion, the molar ratio of ingredients is respectively SiO 2 :Al 2 o 3 =2.5,Na 2 O: SiO 2 =6.07,H 2 O:Na 2 O=10.0; another 1L beaker is placed, and an appropriate amount of Al 2 o 3 Sodium aluminate solution with a concentration of 40g / L and SiO 2 The sodium silicate solution with a concentration of 200g / L is mixed, and a certain amount of sodium hydroxide is added after mixing to make the final mixed solution Na 2 O: SiO 2 It...

Embodiment 3

[0050] Put 100L of 95g / L sodium aluminate solution that has been removed during the production of fly ash into the reaction vessel, raise the temperature of the solution to 75°C, and then boil the washed SiO in the fly ash 2 40g / L, Na 2 O is 85g / L sodium silicate solution 100L continuously adds unwashed and dried semi-finished white carbon black 20kg (moisture content is 50%), then adds lime milk to settle and remove impurities, so that SiO in sodium silicate solution 2 Increase to about 140g / L, the modulus of the solution is about 1, then continuously add the re-dissolved sodium silicate solution into the reaction vessel, stir rapidly at 75°C for 15 minutes, so that the materials are mixed evenly, and the macroscopic performance Be uniform milky white emulsion, the mol ratio of batching is respectively SiO 2 :Al 2 o 3 =2.0, Na 2 O: SiO 2 =1.50,H 2 O:Na 2 O=64.3; put another 1L beaker, put the appropriate amount of Al 2 o 3 Sodium aluminate solution with a concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com