Method for synthesizing NaA-type molecular sieve membrane on inner wall of support body

A molecular sieve and support technology, which is applied in the field of synthesizing NaA molecular sieve membranes on the inner wall of the support, can solve the problems of difficult operation and unusability of the crystal coating method, and achieve good separation selectivity and permeability, excellent performance, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step A. Configure seed liquid

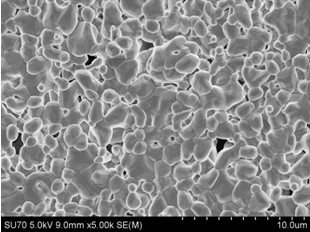

[0034] According to molar ratio Na 2 O: SiO 2 : Al 2 o 3 : H 2 O=20: 2: 1: 2200 Prepare the synthetic solution, weigh a certain quality of sodium silicate and sodium hydroxide and add it to deionized water, stir at room temperature for 15 minutes to completely dissolve it, and weigh a certain quality of sodium aluminate Added into deionized water, stirred at room temperature for 15 minutes to dissolve completely. Then the sodium aluminate solution was slowly added dropwise to the constantly stirring sodium silicate solution. After the dropwise addition, the synthetic solution was continuously stirred at room temperature for 3 hours to complete the aging, and the obtained transparent solution was required for the preparation of the seed solution. The supernatant has a solid content of 5.0 wt.%. The clear liquid was mixed with a 90 nm NaA molecular sieve crystal suspension with a concentration of 1.0 wt.% in a ratio of 1 / 15 to obtain ...

Embodiment 2

[0040] Step A. Configure seed liquid

[0041] With embodiment 1;

[0042] Step B. Pre-coat the seed layer

[0043] With embodiment 1;

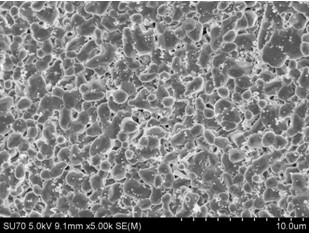

[0044] Step C. Synthesis of Molecular Sieve Membrane

[0045] According to molar ratio Na 2 O: SiO 2 : Al 2 o 3 : H 2 O=7.5: 2: 1: 600 Prepare the synthetic solution, weigh a certain quality of sodium silicate and sodium hydroxide and add it to deionized water, stir at room temperature for 15 minutes to completely dissolve it, and weigh a certain quality of sodium aluminate Added into deionized water, stirred at room temperature for 15 minutes to dissolve completely. Then the sodium aluminate solution was slowly added dropwise to the constantly stirring sodium silicate solution. After the dropwise addition, the synthetic liquid was continuously stirred at room temperature for 3 hours to complete the aging. The synthetic liquid was put into a high-pressure synthesis kettle, and the step In B, the outer wall of the support pre-coated wi...

Embodiment 3

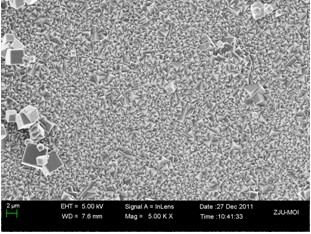

[0047] Step A. Configure seed liquid

[0048] According to molar ratio Na 2 O: SiO 2 : Al 2 o 3 : H 2 O=35: 3: 1: 4200 Prepare the synthetic liquid, weigh a certain quality of sodium silicate and sodium hydroxide and add it to deionized water, stir at room temperature for 15 minutes to completely dissolve it, and weigh a certain quality of sodium aluminate Added into deionized water, stirred at room temperature for 15 minutes to dissolve completely. Then the sodium aluminate solution was slowly added dropwise to the constantly stirring sodium silicate solution. After the dropwise addition, the synthetic solution was continuously stirred at room temperature for 3 hours to complete the aging, and the obtained transparent solution was required for the preparation of the seed solution. The supernatant has a solid content of 4.4 wt.%. The clear liquid and the 260 nmNaA type molecular sieve crystal suspension with a concentration of 0.6% were mixed in a ratio of 1 / 15 to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com