Straw stretching property test device

A testing device and tensile testing technology, which is applied in the direction of measuring device, applying stable tension/pressure to test material strength, strength characteristics, etc., can solve the problem of inability to accurately measure the tensile properties of straw, easy slipping of straw, difficulty in obtaining, etc. problem, to achieve uniform force, reduce damage, and overcome the effects of stretching and slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

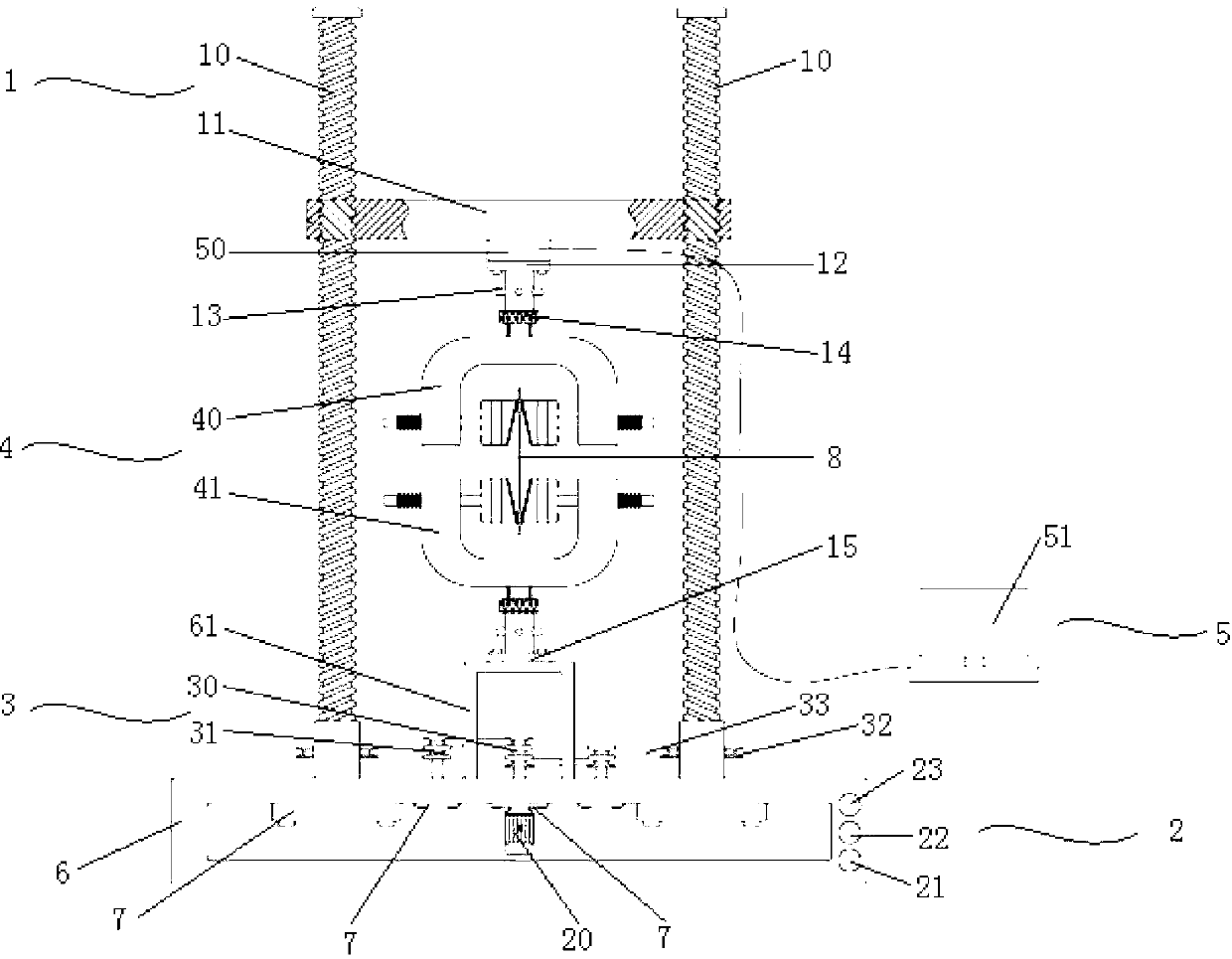

[0020] like figure 1 As shown, the present invention includes a stretching mechanism 1 , a power mechanism 2 , a transmission mechanism 3 , a clamping mechanism 4 , a data information collection and transmission control platform 5 and a frame base 6 .

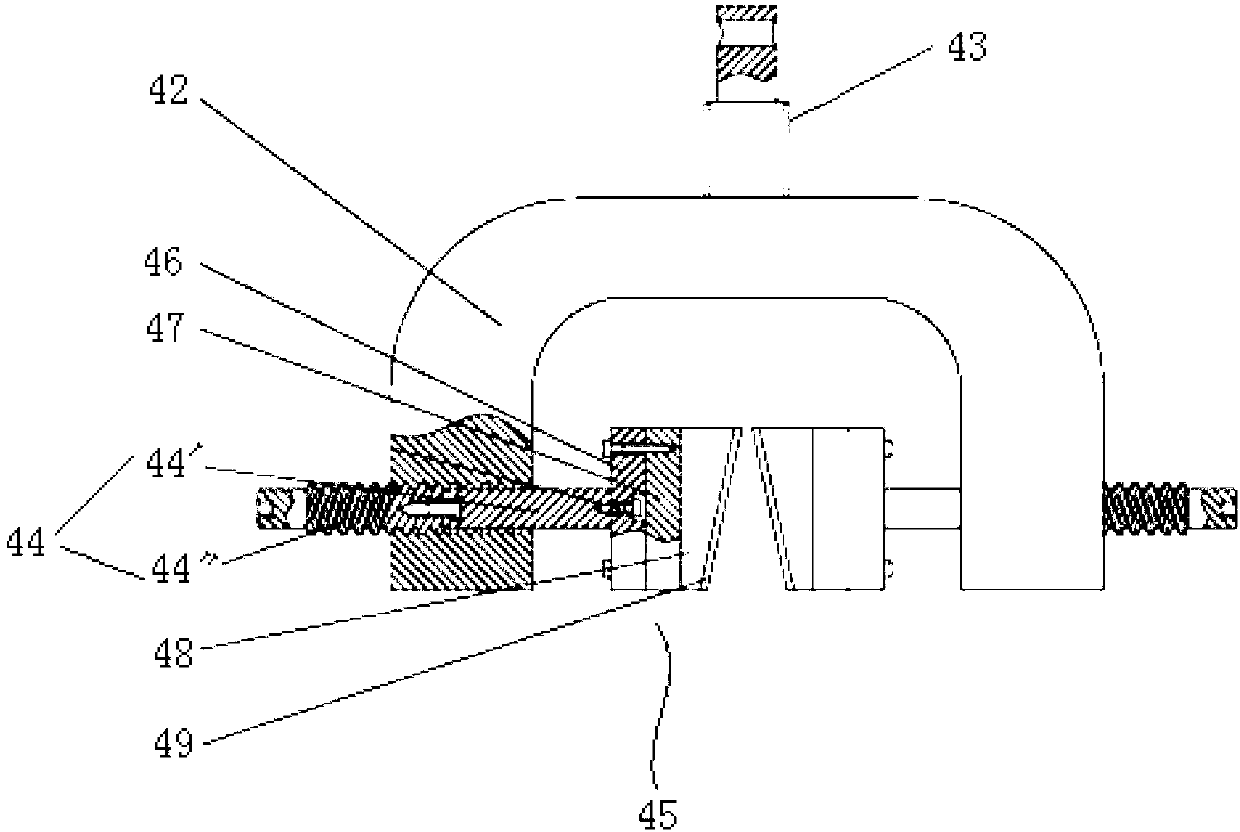

[0021] The stretching mechanism 1 includes two lead screws 10 arranged vertically at intervals. The bottom ends of the lead screws 10 are rotatably arranged on a bearing base assembly 7, and the bearing base assembly 7 is fastened and connected to the frame base 6 by screws. Two lead screws 10 are screwed to a horizontal beam 11, and the center of the lower end of the beam 11 is sequentially connected to a pressure sensor 50 and an upper connecting sleeve 12 through screws, and the upper connecting sleeve 12 passes through a pin shaft 13 and a lock. The tight nut 14 is tightly connected to the upper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com