Fiber web reinforced vulcanized paper and reinforced sand paper

A technology of fiber mesh and shaped steel, applied in the field of fiber mesh reinforced steel paper and reinforced sandpaper, which can solve the problems of easy breakage, poor flexibility of steel paper, easy decomposition, etc., and achieve the effect of high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

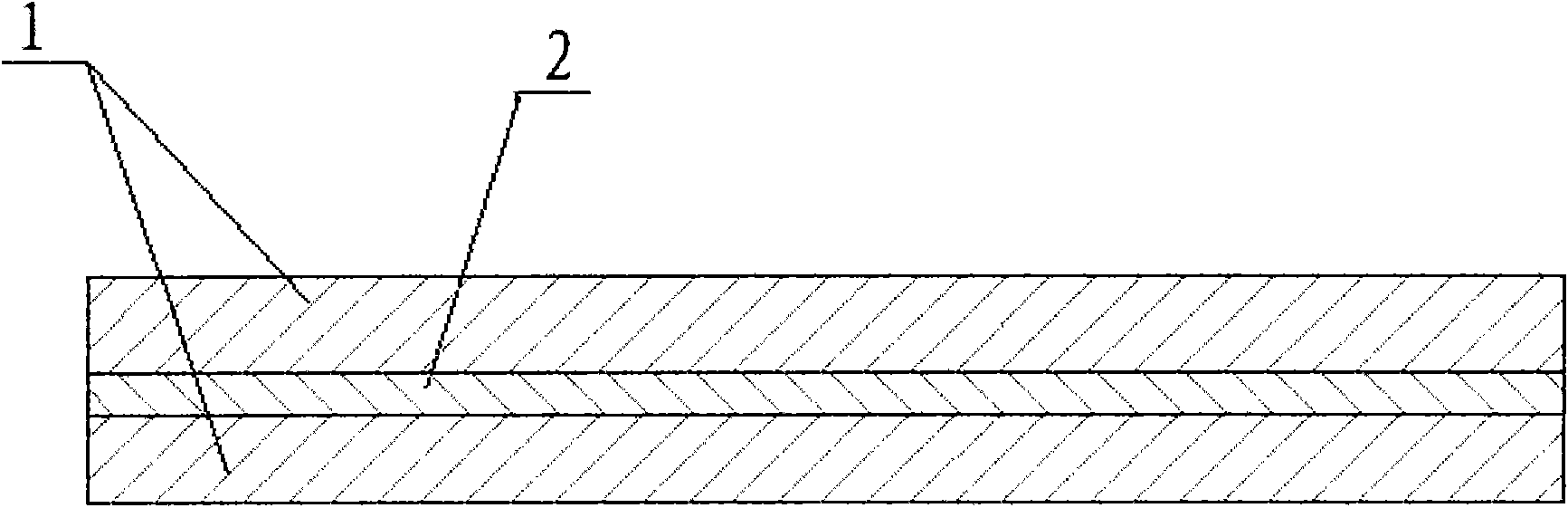

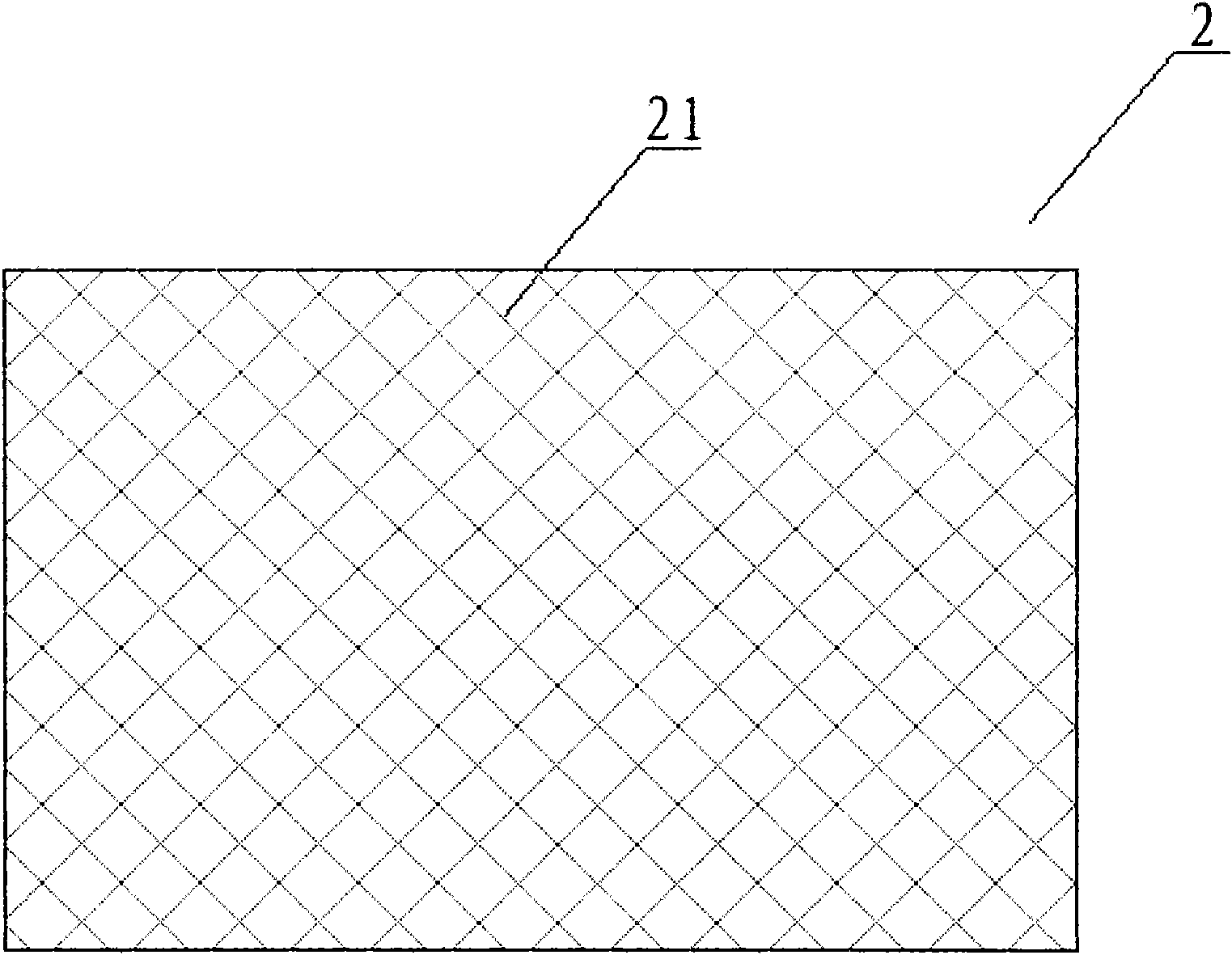

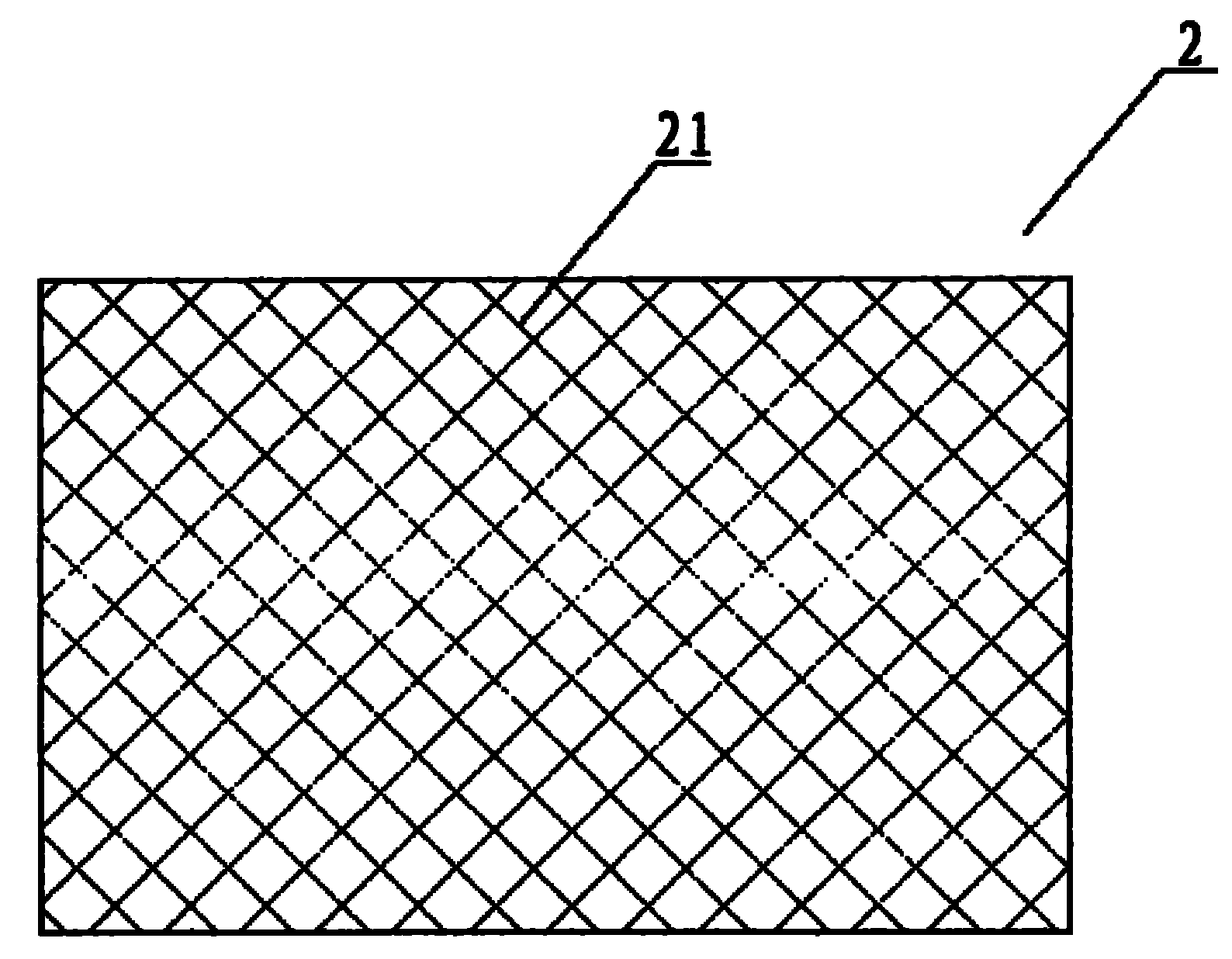

[0021] refer to figure 1 and figure 2 , fiber mesh reinforced steel paper, including a paper fiber layer 1, also includes a fiber mesh skeleton, the fiber mesh skeleton adopts a fiber mesh 2 woven from fiber threads, and the fiber threads are threads made of fibers. The fiber mesh skeleton is embedded in the paper fiber layer 1 .

[0022] The fiber web 2 used is not a fiber web made by simply interlacing fibers, but a fiber web 2 in which the fibers are first made into fiber threads 21 and then woven into fiber threads 21 . Fiber web 2 has better toughness and higher strength than the traditional fiber web made by direct interlacing of fibers, and is not easy to disintegrate. It is still not easy to disintegrate after being exposed to water. It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com