Micro-arc oxidation method of car part aluminum material

A technology of micro-arc oxidation and auto parts, applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of large sewage discharge, sewage discharge, power consumption, etc., and achieve pollution-free and improved electrical insulation performance Durability, simple composition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

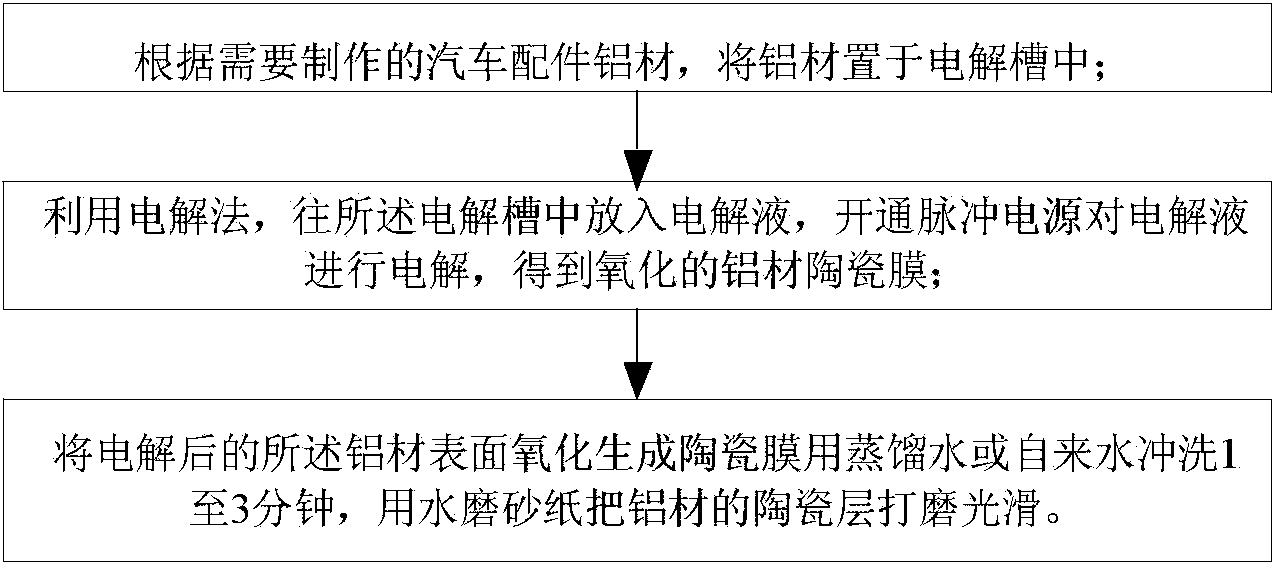

Method used

Image

Examples

example 1

[0028] Place the magnesium-aluminum alloy in the electrolytic cell, inject 11g / L of silicate, 4.6g / L of boric acid, 0.8g / L of potassium hydroxide, 21g / L of hydrogen peroxide, 0.1g / L of citric acid, and silicon carbide into the electrolytic cell 0.1g / L, the remaining part is an electrolyte solution of water, the pH value of the electrolyte solution is guaranteed to be 9, the aluminum-magnesium alloy is used as the anode, the steel plate is used as the cathode, the pulse power supply is a DC power supply, the current density is 5A / dm, and the current frequency 700HZ, increase the voltage from 0 to 200V, keep the heating temperature at 25°C, and the time of micro-arc oxidation is 40min. After a thin layer of ceramic film is formed on the surface of the magnesium-aluminum alloy, rinse it with distilled water or tap water for 1 minute, and polish the ceramic layer on the surface of the aluminum alloy with abrasive paper.

example 2

[0030] Place the magnesium-aluminum alloy in the electrolytic cell, inject 11g / L of silicate, 4.6g / L of boric acid, 0.8g / L of potassium hydroxide, 21g / L of hydrogen peroxide, 0.25g / L of citric acid, and silicon carbide into the electrolytic cell 0.25g / L, the remaining part is an electrolyte solution of water, ensure that the pH value of the electrolyte solution is 11, the aluminum-magnesium alloy is used as the anode, the steel plate is used as the cathode, the pulse power supply is a DC power supply, the current density is 10A / dm, and the current frequency 800HZ, increase the voltage from 0 to 300V, keep the heating temperature at 35°C, and the time of micro-arc oxidation is 45min. After a thin layer of ceramic film is formed on the surface of the magnesium-aluminum alloy, rinse it with distilled water or tap water for 2 minutes, and polish the ceramic layer on the aluminum alloy surface with water abrasive paper.

example 3

[0032] Place the magnesium-aluminum alloy in the electrolytic cell, inject silicate 11g / L, boric acid 4.6g / L, potassium hydroxide 0.8g / L, hydrogen peroxide 21g / L, citric acid 0.5g / L, silicon carbide 0.5 g / L, the remaining part is an electrolyte solution of water, ensure that the pH value of the electrolyte solution is 13, the aluminum-magnesium alloy is used as the anode, the steel plate is used as the cathode, the pulse power supply is a DC power supply, the current density is 15A / dm, and the current frequency is 900HZ , the voltage range is 350V, the heating temperature is kept at 45°C, and the time of micro-arc oxidation is 50min. After a thin layer of ceramic film is formed on the surface of the magnesium-aluminum alloy, rinse it with distilled water or tap water for 3 minutes, and polish the ceramic layer on the surface of the aluminum alloy with sandpaper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com