Automatic metallographic specimen polishing device

A metallographic sample and automatic technology, applied in the field of mechanical polishing devices, can solve the problems of low work efficiency and high labor intensity, achieve high work efficiency and operation safety, and automatically change the polishing direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

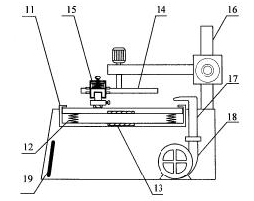

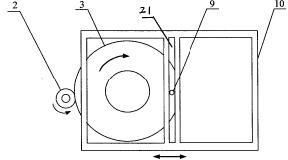

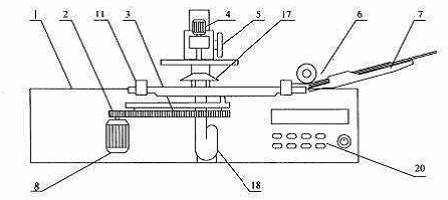

[0011] An automatic polishing device for metallographic samples, comprising a cabinet 1, a vertical arm 16 is fixedly arranged on the surface of the cabinet 1, a horizontal beam is arranged on the vertical arm 16, and a movable beam is arranged at the end of the horizontal beam. The lifting adjustment platform 5 is provided with a steering motor 4 on the lifting adjustment platform 5, and the output shaft protruding downwards of the steering motor 4 is connected with a sample disc 14, and the sample disc 14 is provided with a facing downward. Sample holder 15, sample is provided with in sample holder 15, is provided with sandpaper fixture box 11 on the box face of cabinet 1, is provided with sandpaper consultation wheel 6 and sandpaper tray 7 at one side of sandpaper holder box 11, in A rectangular sandpaper disc 10 is arranged in the sandpaper fixture box 11, a chute 21 is arranged on the rectangular sandpaper disc 10, a pin shaft 9 is movably arranged in the chute 21, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com