Transferable wearing-resistant flexible super-hydrophobic film and preparation method thereof

A super-hydrophobic and thin-film technology, which is applied in the direction of pretreatment surface, epoxy resin coating, polyurea/polyurethane coating, etc., can solve the problems of non-repairability, difficulty of replacement, secondary pollution, etc., to broaden the scope of use, The effect of roughening the surface and maintaining integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

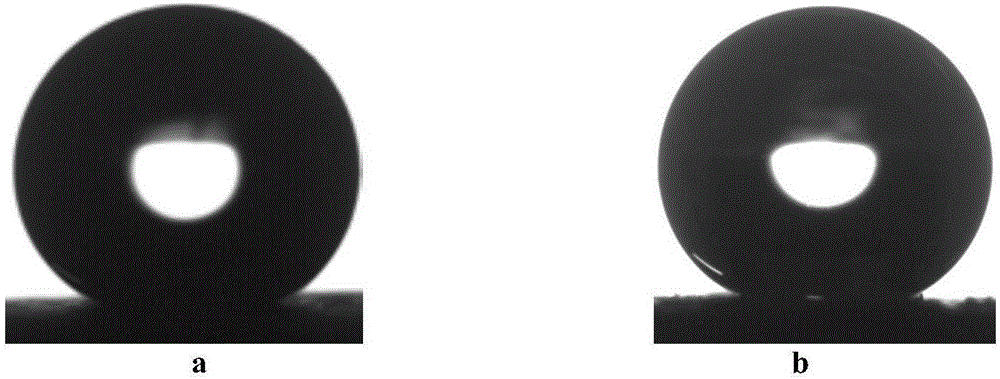

[0053] A transferable wear-resistant flexible super-hydrophobic film is a non-fixed and transferable film-like material with good wear resistance, durability and elasticity, which can be bent and folded, and can be cut to any shape as required, and glued Connected to the surface of substrates of various materials and shapes to obtain super-hydrophobicity. The preparation method steps are:

[0054] (1) Primer preparation and preparation: add 5-40 parts by mass of soft and hard composite resin and its curing agent to 100-500 parts by mass of diluent, ultrasonically stir for 30-120 minutes, then mechanically stir for 2-30 minutes, then add 0-50 parts of micro-powder and 0-5 parts of additives, continue stirring for 10-60 minutes to obtain a uniformly dispersed hybrid primer. Form a uniform coating on the surface of the material, adjust the coating thickness to 0.5 μm ~ 5mm, and cure at room temperature for 30 ~ 120 minutes; the weight ratio of soft resin to hard resin is 0.1 ~ 1...

Embodiment 1

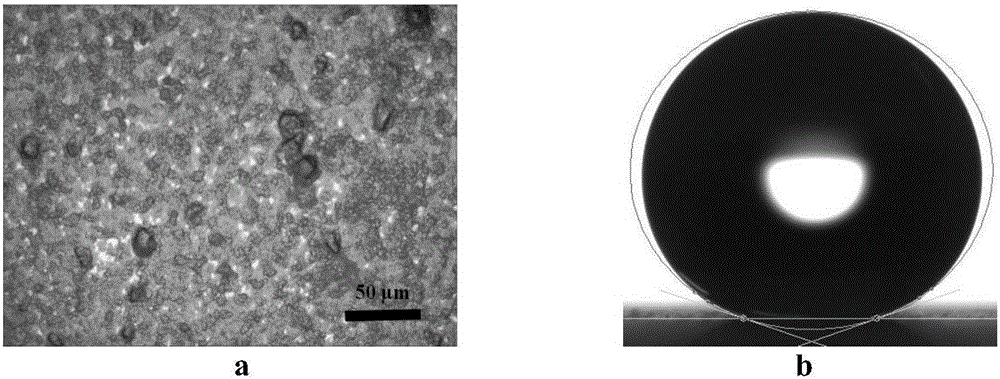

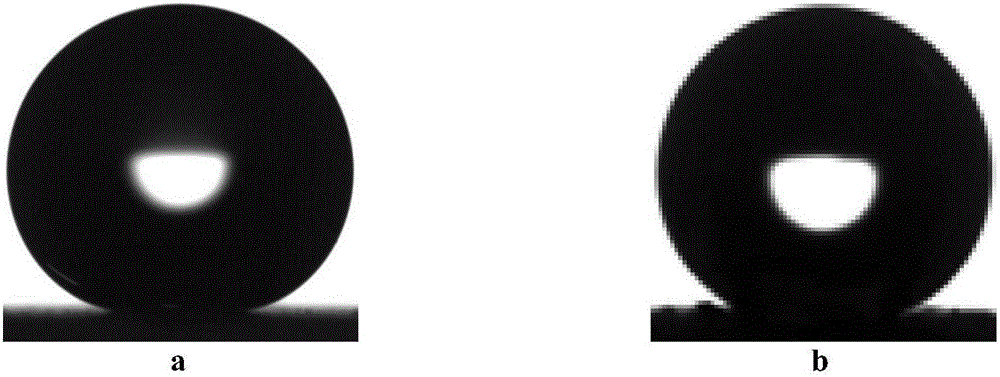

[0068] Dissolve 5g of dimethylsiloxane and 5g of polymethyl methacrylate in 100g of acetone, ultrasonicate for 30min, then mechanically stir for 2min, then add 1g of microsilica powder and 0.1g of additives, which contain fluids of equal mass specific gravity Leveling agent BYK-358, defoamer BYK-555, dispersant BYK-161 and anti-sedimentation agent fumed silica, continue to stir for 30 minutes to obtain a uniformly dispersed hybrid primer, and stand for degassing for 10 minutes to obtain a primer coating; Disperse 1 g of hydrophobic zinc oxide nanoparticles with a particle size of 5-200 nm in 100 mL of acetone solution, and obtain a uniformly dispersed super-hydrophobic coating after ultrasonic dispersion and mechanical stirring for 30 min; A uniform coating is formed on the surface of the toughened glass, and after curing for 30 minutes, the superhydrophobic coating prepared above is sprayed on the surface. Finally, the composite superhydrophobic film prepared above is placed i...

Embodiment 2

[0070] Dissolve 10g of polyethylene and 5g of FEVE fluorocarbon resin in 200g of butyl acetate, ultrasonicate for 60 minutes, then mechanically stir for 10 minutes, then add 5g of hollow microspheres, continue stirring for 30 minutes to obtain a uniformly dispersed hybrid primer, and let it stand for degassing for 30 minutes Finally, the primer coating was obtained; 2 g of silicon dioxide hydrophobic nanoparticles with a particle size of 5 to 200 nm were dispersed in 100 mL of butyl acetate solution, and a uniformly dispersed superhydrophobic coating was obtained after ultrasonic dispersion and mechanical stirring for 30 min; the above primer Spray the lacquer coating on the surface of the degreased and decontaminated glazed tiles to form a uniform coating. After curing for 60 minutes, spray the super-hydrophobic coating prepared above on the surface. Finally, put the composite super-hydrophobic film prepared above in an oven at 150°C After solidifying for 1 hour and separating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com