Metallographic test sample preparation instrument

A metallographic sample and clamping mechanism technology, which is applied in the preparation of test samples, metal processing equipment, manufacturing tools, etc. Inequality problem, to avoid sample preparation defects, save manpower and time, and achieve the effect of high equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

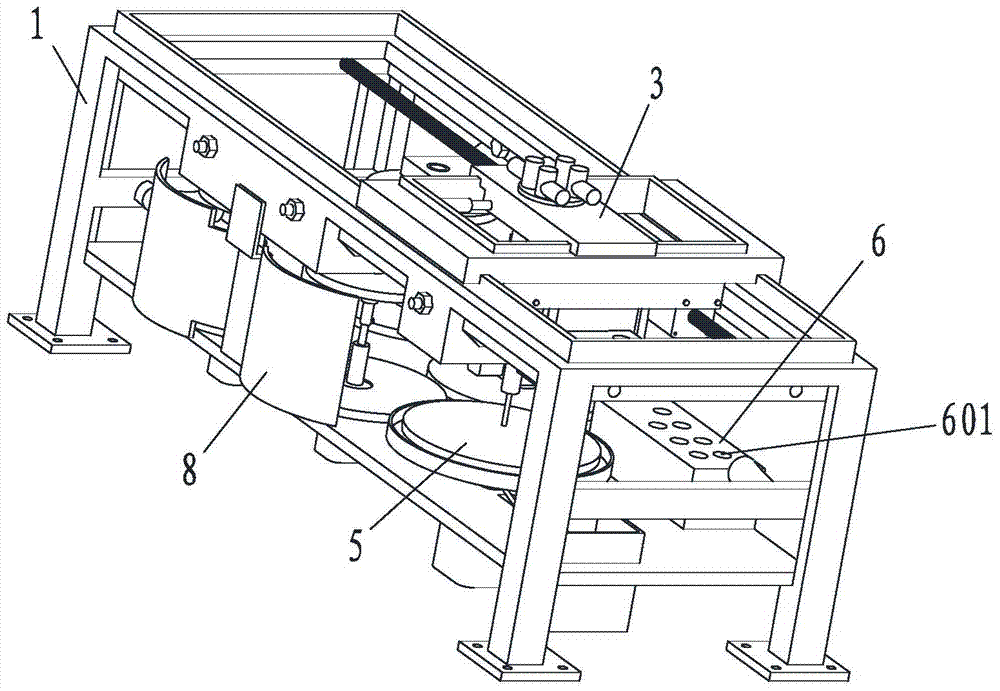

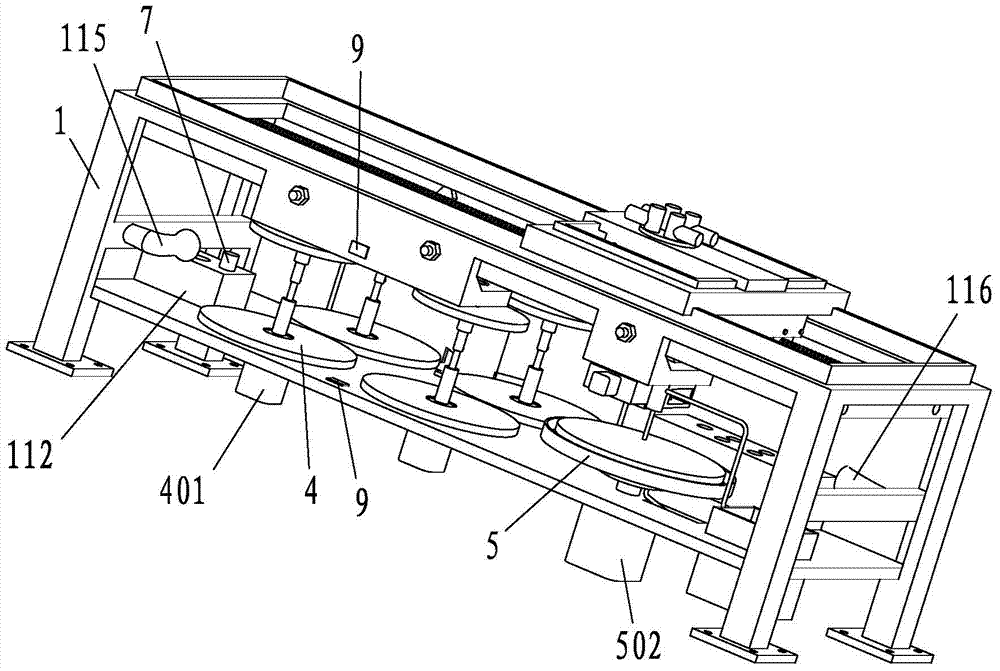

[0077] combine figure 1 with figure 2 As shown, a metallographic sample preparation instrument includes a frame 1 , a metallographic sample clamping mechanism 2 , a five-degree-of-freedom driving mechanism 3 , a grinding mechanism 4 , a polishing mechanism 5 and a sample corrosion structure block 6 .

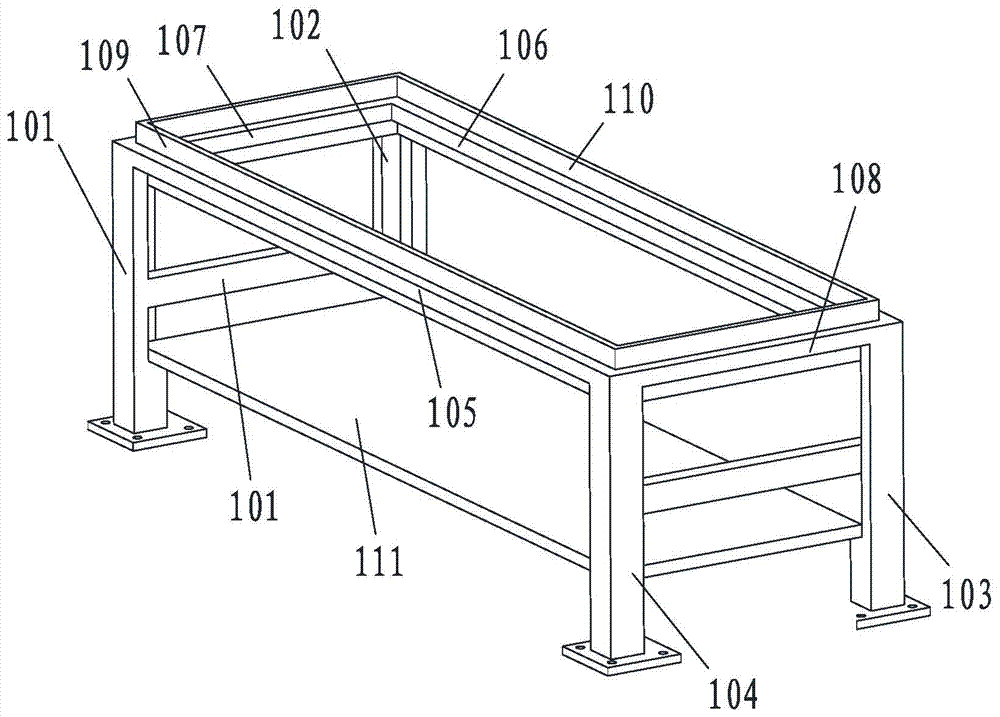

[0078] Such as image 3 As shown, the rack 1 is square and includes columns 101 , 102 , 103 , 104 .

[0079] A first horizontal support column 105 , 106 is respectively arranged between the upright column 101 and the upright column 104 , and between the upright column 102 and the upright column 103 . A second horizontal support column 107 , 108 is respectively arranged between the column 101 and the column 102 , and between the column 103 and the column 104 . The length of the first horizontal support column 105 , 106 is greater than the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com