Injection-tube-free thin film vapor chamber for portable electronic devices and manufacturing method thereof

A technology for electronic equipment and a manufacturing method, which is applied to structural parts of electrical equipment, portable housings, lighting and heating equipment, etc., can solve the problems of broken injection pipes, increased product defect rate, and difficulty in combining injection pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, specific embodiments for carrying out the present invention will be described with reference to the drawings. The embodiments of the present invention are intended to illustrate an invention, so the scope of rights is not limited to the exemplary embodiments, and the illustrated drawings only expand and illustrate the core content of the invention for the clarity of the invention, and omit the subsidiary parts, so it cannot be limited Explain with the accompanying drawings.

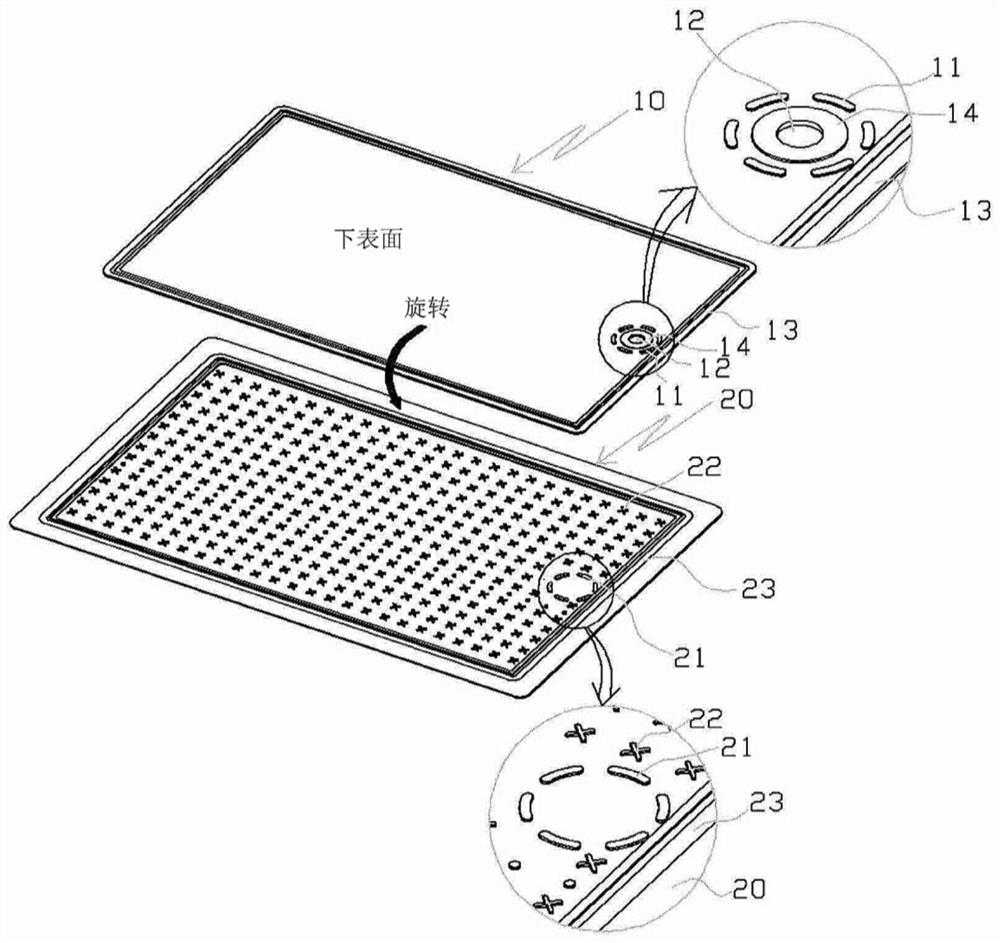

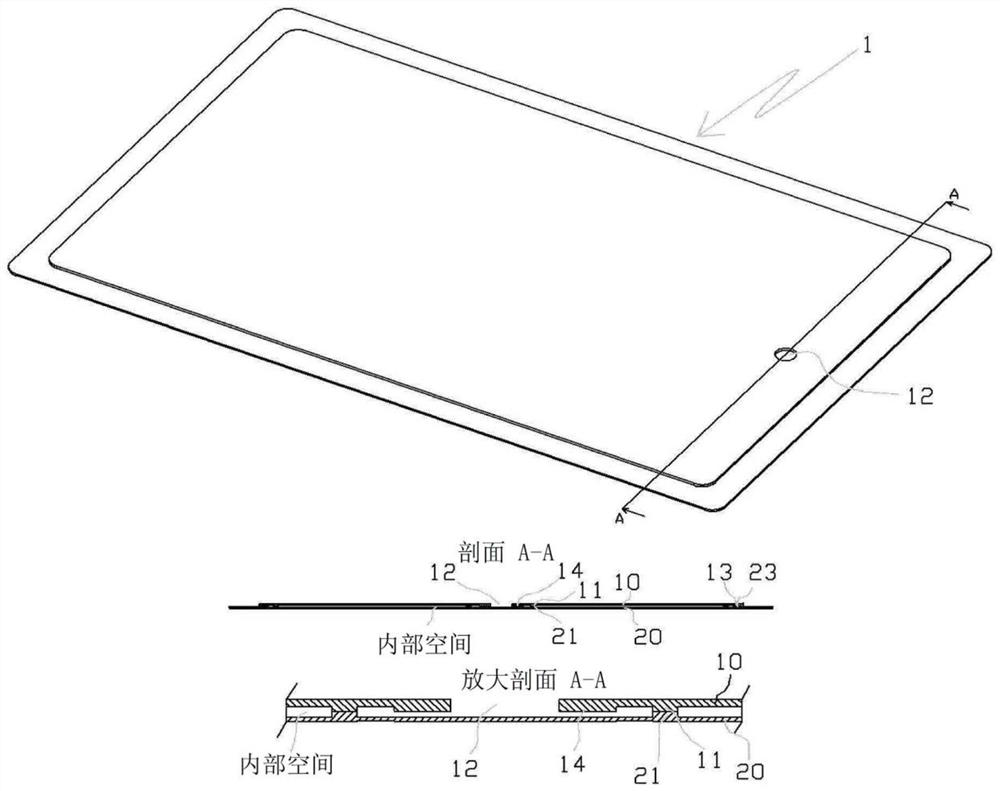

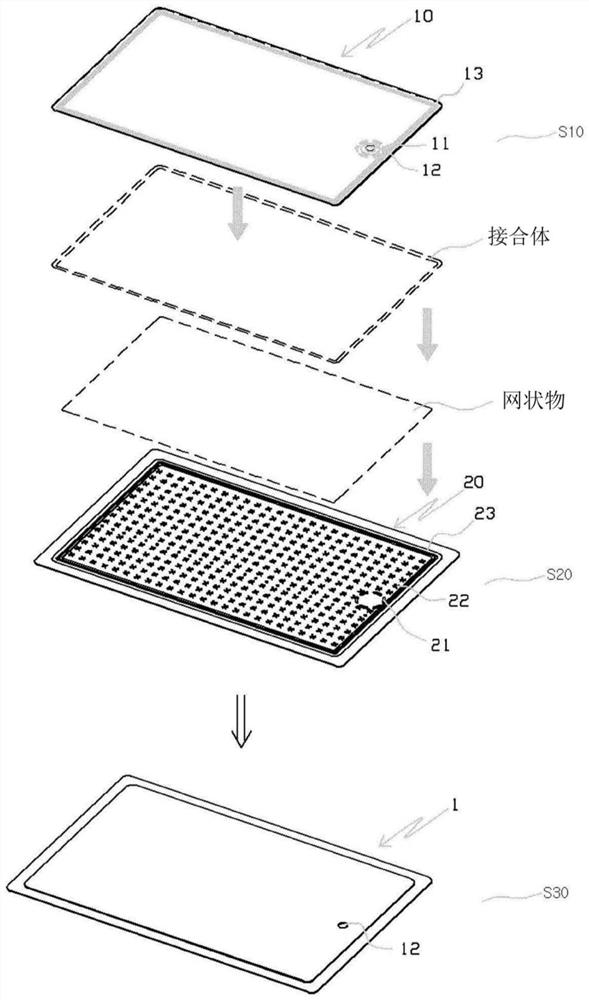

[0041] According to the vapor chamber (VaporChamber) provided in the portable electronic device provided by the present invention, it is characterized in that it includes: a lower plate 20, which is formed into a metal plate shape, and a plurality of protrusions are formed on its upper surface 22, and the upper surface of one side is formed with a plurality of first projections 21 spaced apart and protruding at predetermined intervals, and a first engaging body 23 is formed from the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com