Welding flexible general assembly precision on-line detection apparatus and method

A precision detection and detection device technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve problems affecting normal production, long detection time, time-consuming and laborious, etc., to improve the frequency of precision monitoring and avoid manufacturing defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing.

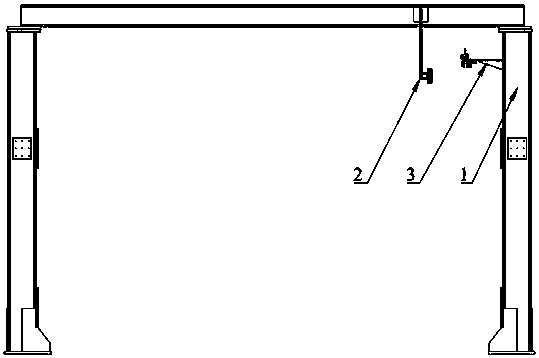

[0032] like figure 1 The shown on-line detection device for welding flexible assembly accuracy includes a mounting frame 1 , a state acquisition unit 2 , an accuracy detection unit 3 and a data processing unit 4 .

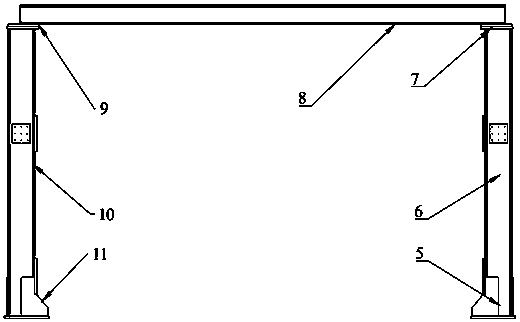

[0033] like figure 2 As shown, the installation frame 1 is installed on the steel plate of the foundation of the workshop, and is used for installing the state acquisition unit 2 and the accuracy detection unit 3 . The mounting frame 1 is a gantry frame, which includes a front column 6 and a rear column 10 relatively vertically arranged, and a crossbeam 8; The lower end is provided with front foot 5;

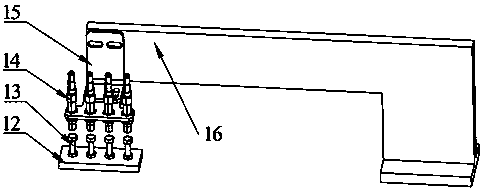

[0034] like image 3 As shown, the state acquisition unit 2 is installed on the mounting frame 1, and the state acquisition unit 2 includes the vehicle type induction bolt 13 arranged (by welding) on the tested unit 28, and is installed on the installation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com