Full-resin water-resistant sand paper

A resin and sandpaper technology, used in abrasives, metal processing equipment, manufacturing tools, etc., can solve problems such as large pollution and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

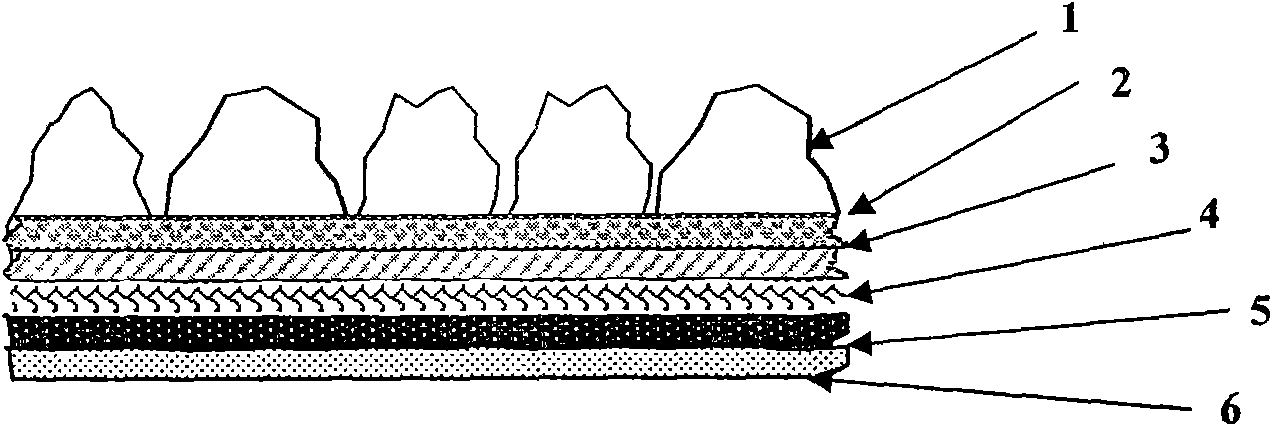

[0018] Example 1, consists of six layers, from top to bottom are abrasive layer 1, adhesive layer 2, basic adhesive layer 3, sand surface treatment layer 4, sandpaper base paper layer 5 and waterproof treatment layer 6. The adhesive layer is a mixture of 100 parts of urea-formaldehyde resin, 6 parts of iron red and 0.5 part of ammonium chloride. The base adhesive layer is a mixture of 70 parts water-soluble acrylic resin, 30 parts amino resin, 5 parts flour and 5 parts iron red. The sand surface treatment layer is a mixture of 50 parts of nano-sized styrene-butadiene latex, 30 parts of modified starch solution, 20 parts of water and 1 part of penetrant JFS. The waterproof treatment layer is a mixture of 100 parts of nano-styrene-butadiene latex and 1 part of penetrant JFS.

[0019] Example 2, the same example 1, the difference is that the adhesive layer is a mixture of 90 parts of urea-formaldehyde resin, 8 parts of iron red and 2 parts of ammonium chloride. The base adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com