Linear reciprocating type pre-milling machine

A reciprocating, pre-grinding technology, applied in grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of high price, dangerous turntable, time-consuming and labor-intensive, etc., so as to improve polishing accuracy and improve polishing efficiency. , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

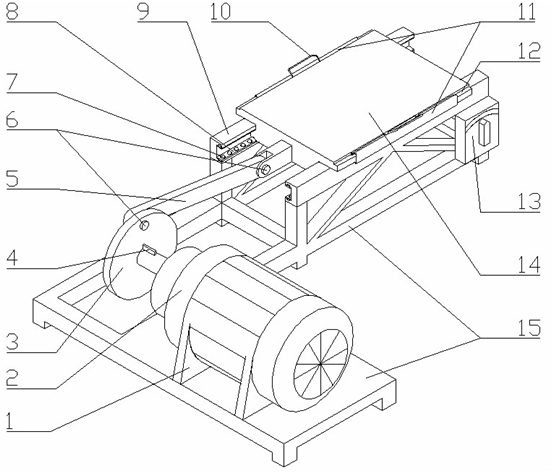

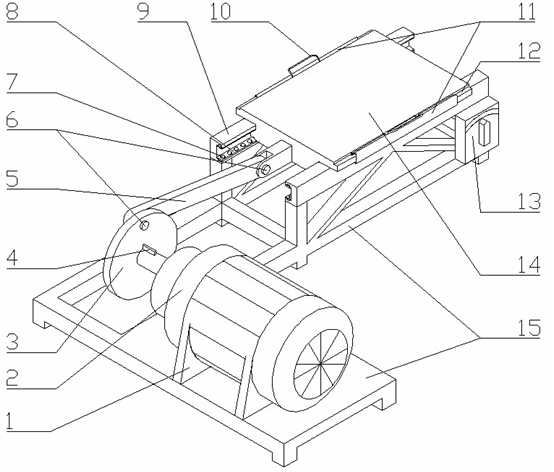

[0016] In order to make the purpose, technical solution and advantages of the present invention clearer, the device of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

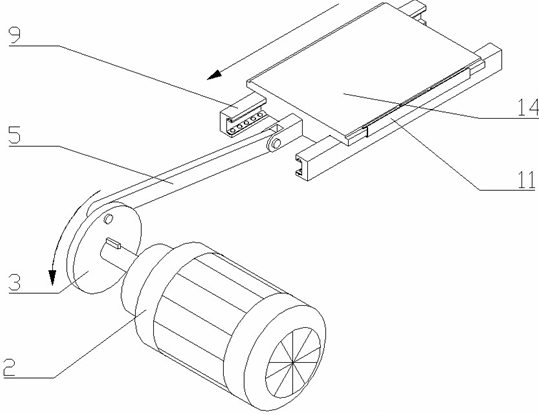

[0017] A kind of linear reciprocating pre-grinding machine of the present invention is made up of grinding platform, reciprocating link mechanism, electric motor 2, support 15 four parts.

[0018] The grinding platform is composed of a linear guide rail 9, a flat grinding plate 14, and a sandpaper fixing fixture 11; the linear guide rail adopts an I-shaped rolling friction guide rail, and the linear guide rail 9 is fixed on the support 15 through bolts and nuts; the rolling steel ball 7 is placed on the I-shaped In the inner concave groove of the linear guide rail 9, there is a row on the upper and lower sides, which are fixed by the cage 8; the flat grinding plate 14 adopts a slider structure, that is, as the moving element of the li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com