Automatic nitrogen pressure regulating control device of refining and cracking buffer tanks

A technology of automatic control device and buffer tank, which is applied in the direction of electric fluid pressure control, feeding device, pressure vessel used in chemical process, etc., which can solve the problem of affecting normal operation, limitation of reaction system operation stability, and fluctuation of feed flow Increase and other problems, to achieve the effect of stable pressure, reasonable structure design, and stable pressure control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

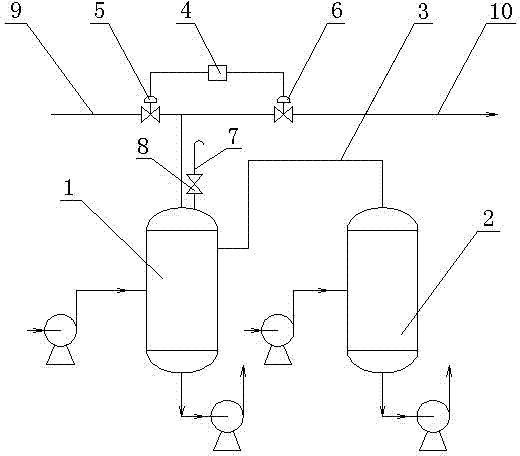

[0009] The automatic control device for nitrogen pressure regulation of the refining and cracking buffer tank of the present invention is composed of a cracking buffer tank 1, a refining buffer tank 2 and a nitrogen pressure pipeline 9. The device is to connect the top pipeline 3 of the refining buffer tank 2 to the cracking buffer The upper part of the tank 1, the top of the cracking buffer tank 1 is connected with the nitrogen pressure pipeline 9 through the nitrogen control valve 5, and the vent line 10 connected through the vent valve 6 is arranged between the top of the cracking buffer tank 1 and the nitrogen control valve 5, and the nitrogen The control valve 5 and the vent valve 6 are electrically connected to the pressure balance switch controller 4 .

Embodiment 2

[0011] Such as figure 1 As shown, the automatic control device for refining and cracking buffer tank nitrogen pressure regulation of the present invention comprises a cracking buffer tank 1, a refining buffer tank 2 and a nitrogen pressure pipeline 9, and the device is to connect the top pipeline 3 of the refining buffer tank 2 To the upper part of the cracking buffer tank 1, the top of the cracking buffer tank 1 is connected to the nitrogen pressure pipeline 9 through the nitrogen control valve 5, and the venting pipeline connected through the vent valve 6 is arranged between the top of the cracking buffer tank 1 and the nitrogen control valve 5 10. The nitrogen control valve 5 and the vent valve 6 are electrically connected to the pressure balance switch controller 4 . The top of the cracking buffer tank is provided with a manual vent pipe 7 and a manual vent pipe control valve 8 .

[0012] When the discharge pumps of the refining buffer tank and the cracking buffer tank op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com