Pressure relief and diversion structure of water storage bottle for automobile

A technology for water storage bottles and automobiles, applied in engine components, machines/engines, engine cooling, etc., can solve the problems of lack of protective measures, pollution, unstable pressure control, etc., to reduce manufacturing difficulty, manufacturing cost, pressure Controlling stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

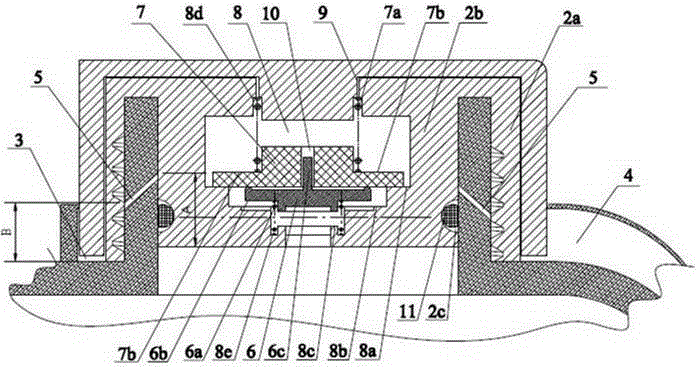

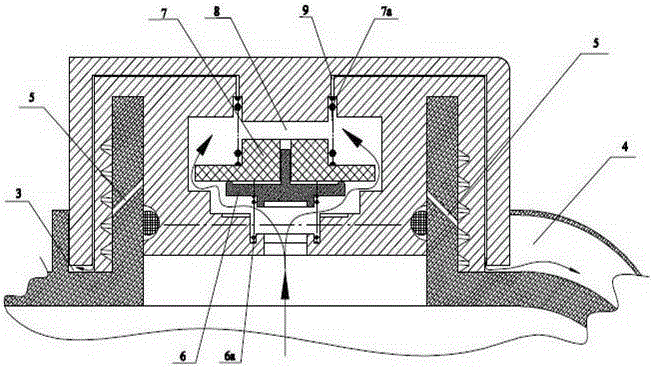

[0018] Below in conjunction with accompanying drawing, the present invention will be further described:

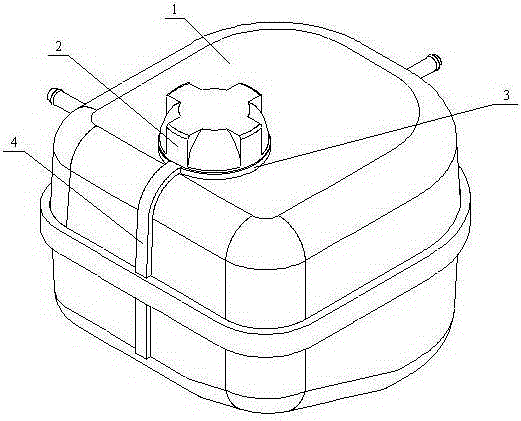

[0019] Such as figure 1 , figure 2 As shown, a pressure relief and diversion structure for a water storage bottle for automobiles includes a bottle body 1 and a bottle cap 2, and also includes an annular groove 3 surrounding the lower end of the neck of the bottle body 1, which serves to gather high-temperature and high-pressure steam. effect of the liquid mixture. The bottle cap 2 is divided into an outer cap 2a and a cap plug 2b. There is a bottle cap inner cavity 8 at the center of the cap plug 2b, in which an intake and exhaust valve is installed to control the intake and exhaust of the engine cooling system respectively. An active venting channel 9 is provided inside the outer cover 2 , one end of which is connected to the inner cavity 8 of the bottle cap, and the other end extends into the annular groove 3 ; a manual venting hole 5 is provided in the middle of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com