Water storage bottle cap for engine cooling system

A technology for engine cooling and water storage bottles, which is applied in the direction of engine cooling, engine components, machines/engines, etc. It can solve the problems of complex structure of bottle caps, difficult processing, and discomfort of the whole vehicle, and achieves control accuracy that is easy to guarantee, The effect of reducing the difficulty of production and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

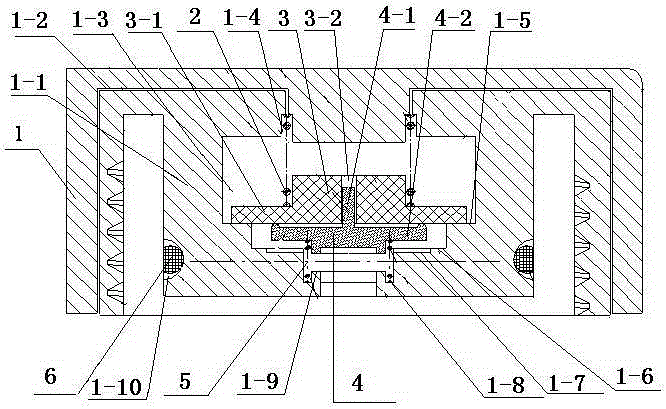

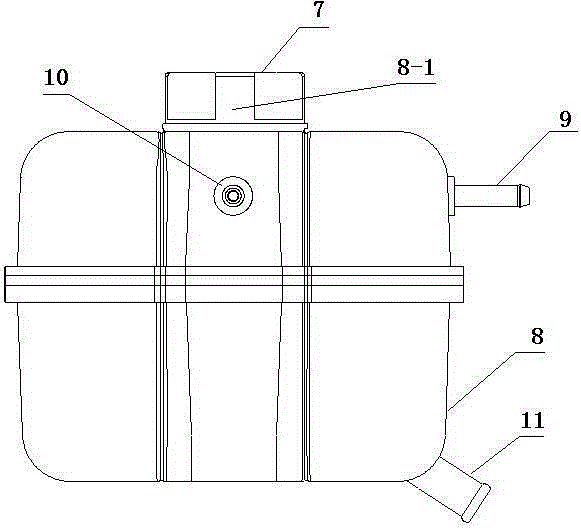

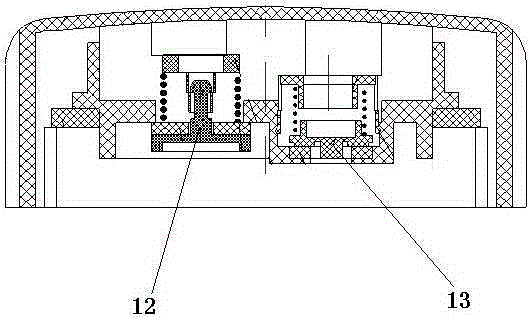

[0028] Such as figure 1 with figure 2 The water storage bottle cap of the engine cooling system shown mainly includes an outer cover 1, a bottle stopper 1-1, an exhaust valve spring 2, an exhaust valve 3, an intake valve 4 and an intake valve spring 5, and the outer cover 1 It is integral with the bottle stopper 1-1, and the outer cover 1 is threadedly connected with the outer wall of the bottle mouth 8-1, and the cover plug 1-1 is closely attached to the inner wall of the bottle mouth 8-1. An annular groove 1-10 is formed on the outer surface, and the sealing ring 6 is set in the annular groove 1-10. The center of the cap plug 1-1 has a stepped hole 1-3 that communicates with the bottle body 8 downwards. The stepped hole 1-3 consists of a first step 1-5, a second step 1-6 and a third step from top to bottom. 1-9 are divided into three stages in turn, the inner diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com