Air conditioner device

An air-conditioning, outdoor-side technology, used in compressors with reversible cycles, compressors, damage protection, etc., can solve problems such as refrigerant noise, increased pressure loss, and increased piping diameter, achieving high reliability, oil Small fluctuation and small pressure fluctuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

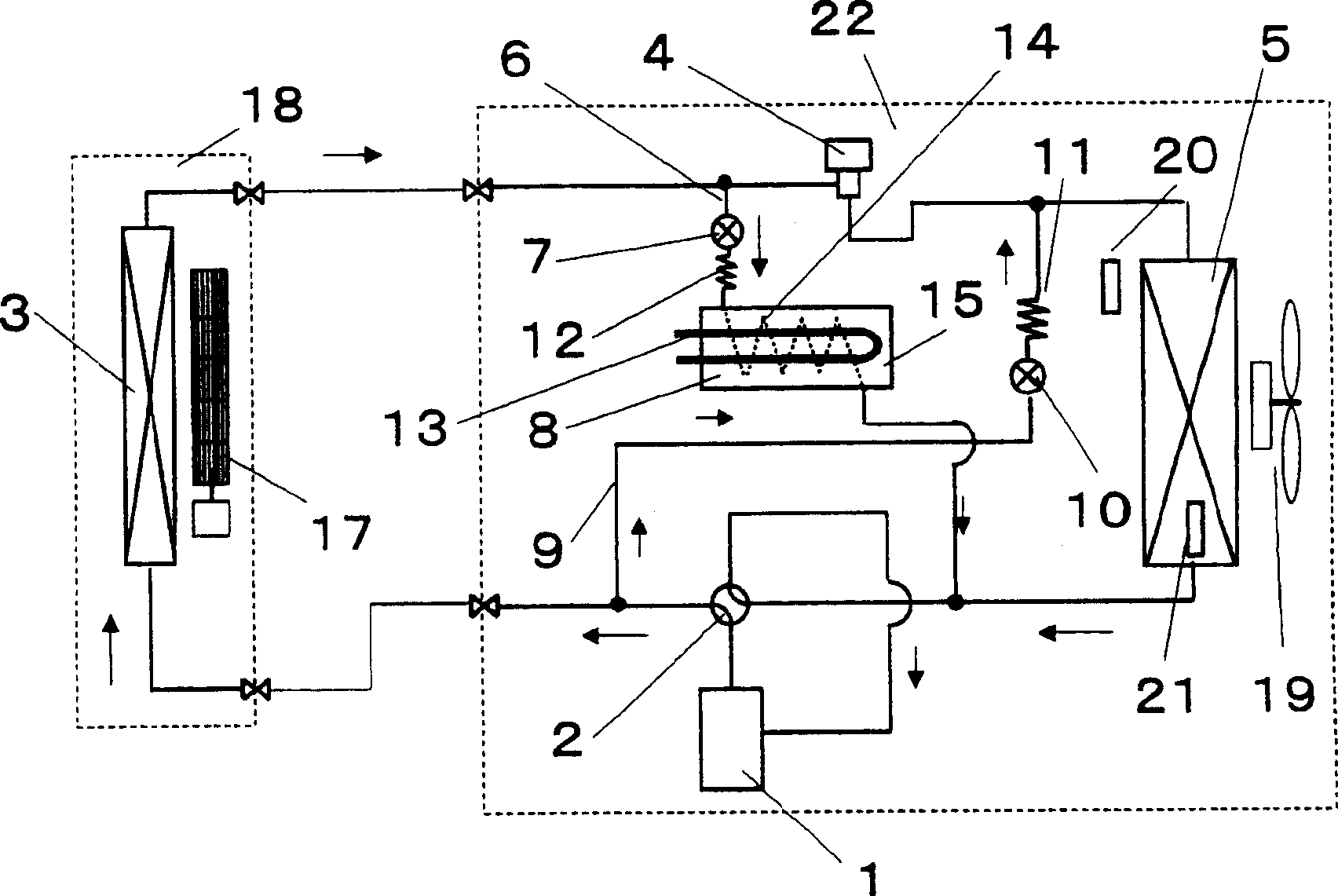

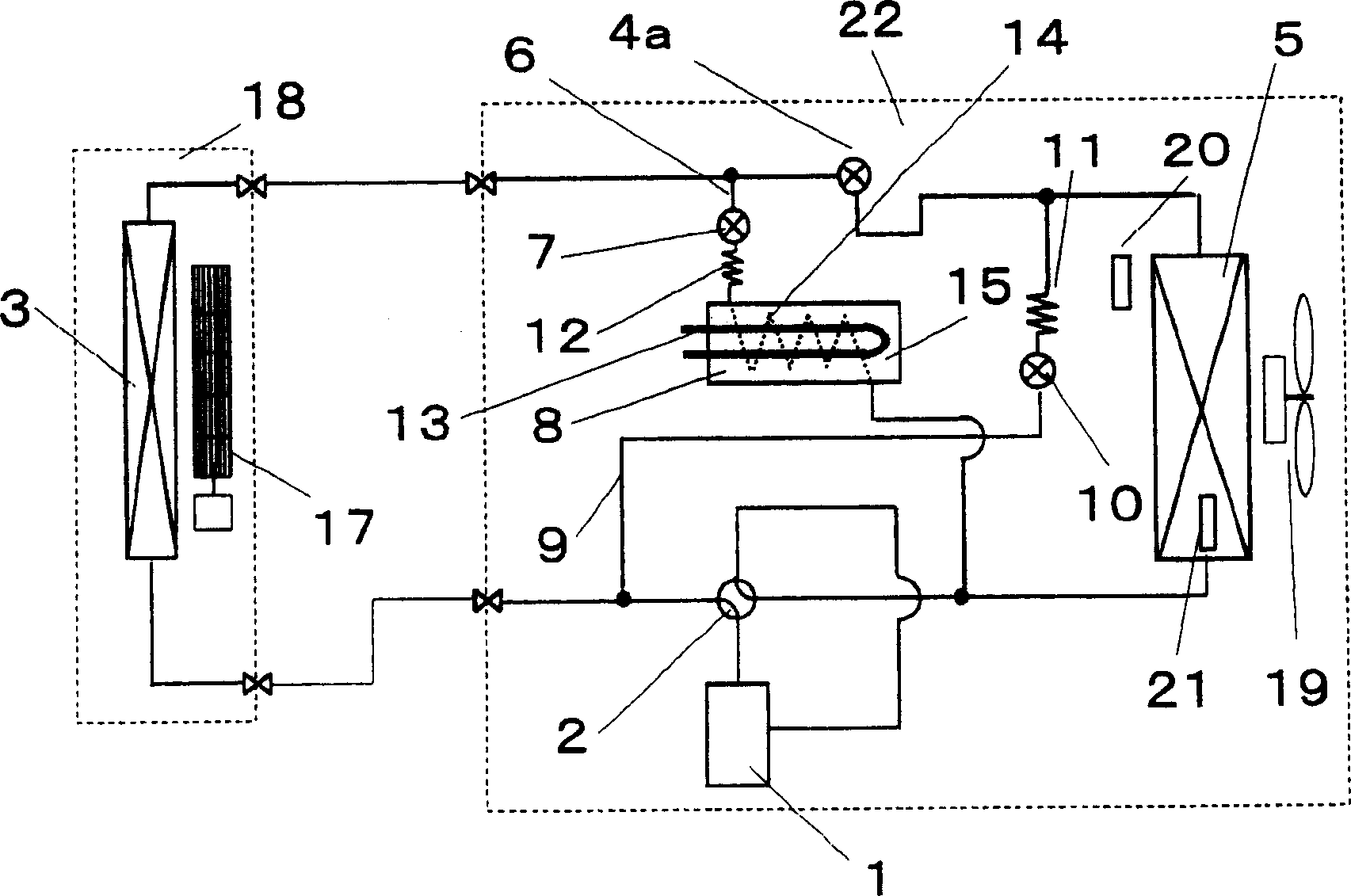

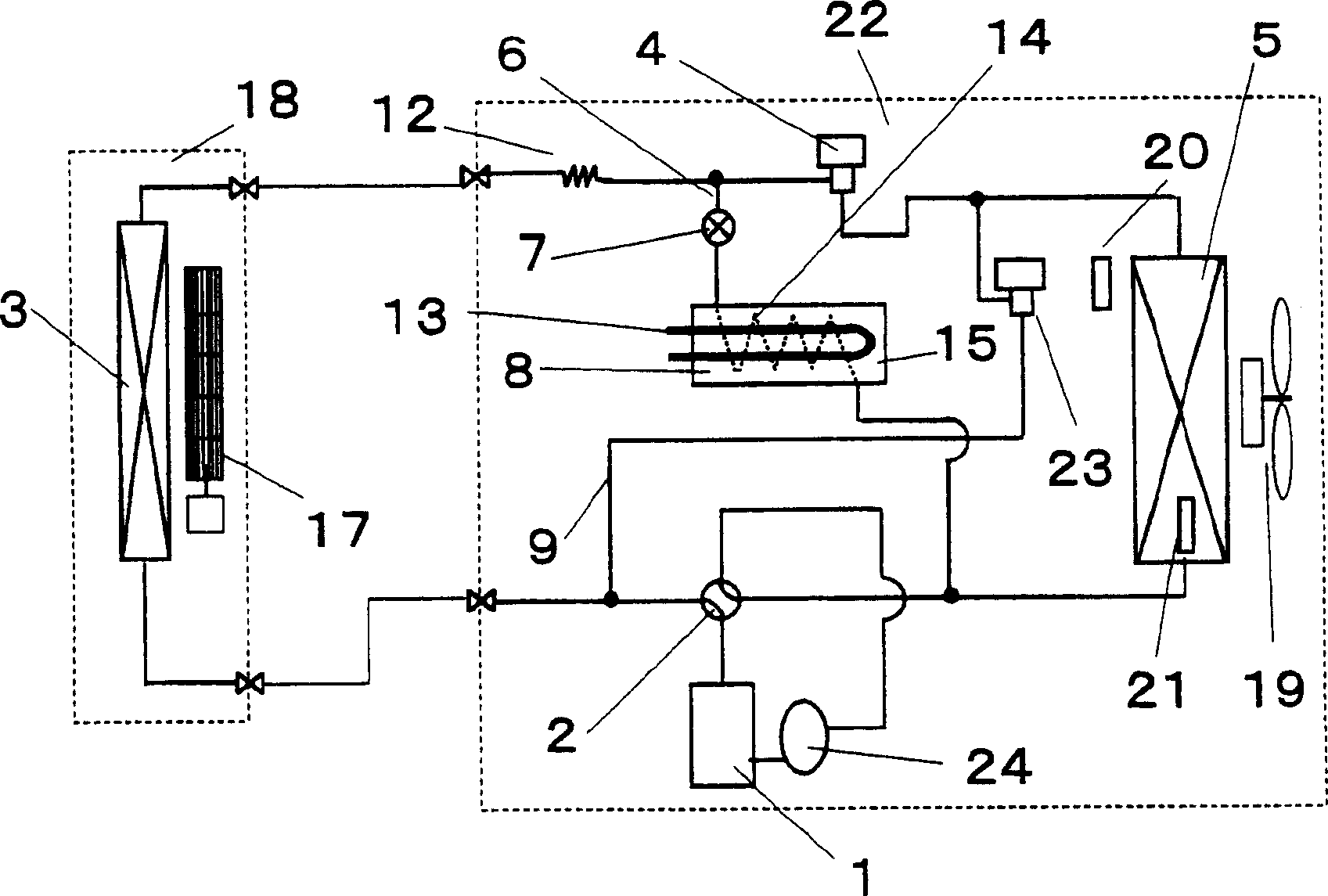

[0045] figure 1 It is a block diagram of the air-conditioning apparatus of 1st Embodiment of this invention. In the same figure, the outdoor unit 22 is equipped with: a compressor 1, a four-way valve 2, a pressure reducer 4, an outdoor side heat exchanger 5, a first bypass circuit 6, a two-way valve for refrigerant heating 7, a refrigerant Heater 8, second bypass circuit 9, two-way valve 10 for defrosting of the second bypass circuit, pressure reducer 11 of the second bypass circuit, two-way valve 7 of the first bypass circuit, first bypass The pressure reducer 12, the refrigerant heating heat source 13, the refrigerant passage pipe 14, the heat storage part 15, the outdoor air blower 19, the outdoor temperature detection part 20, and the outdoor heat exchanger temperature detection part 21 pass through the circuit.

[0046] The indoor unit 18 is equipped with an indoor heat exchanger 3 and an indoor blower 17 . The pressure reducer 4 here may be an electromagnetic expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com