Rotary heat accumulating type heat exchanger

A heat exchanger, heat storage technology, used in heat exchange equipment, heat storage equipment, indirect heat exchangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

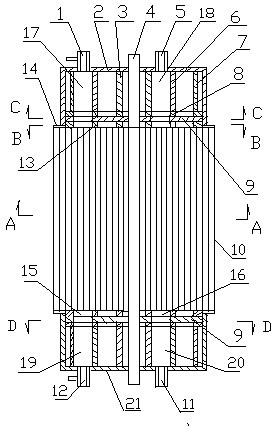

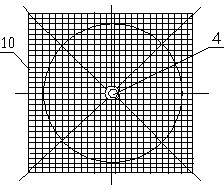

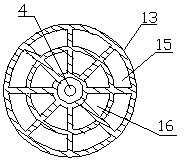

[0020] in figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 in, figure 2 Indicates the cross section of the heat storage body 10, image 3 Indicates the cross section of the circumferential divider 13, Figure 4 Represents the cross section of the valve seat 9 of the cold end, Figure 5 Shows the cross section of the valve seat 9 of the hot end. The rotary regenerative heat exchanger includes a heat storage body 10, a rotating shaft 4 and a disc-type rotary valve. The heat storage body 10 is a heat storage body made of honeycomb ceramics. Of course, the heat storage body is preferably an alumina-based honeycomb. It is made of ceramics. The honeycomb ceramic heat storage body has the characteristics of high temperature resistance, acid and alkali resistance and corrosion resistance and large specific surface area. The heat storage body is cubic, or cylindrical or other shapes. The upper end of the heat storage body is the cold end. The lower end is the hot end. The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com