Manufacturing method of fiber

A manufacturing method and optical fiber technology, applied in the field of optical fiber manufacturing, can solve problems such as the increase of the outer diameter variation of the optical fiber, and achieve the effects of suppressing the outer diameter variation, reducing the natural convection, and reducing the pressure variation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

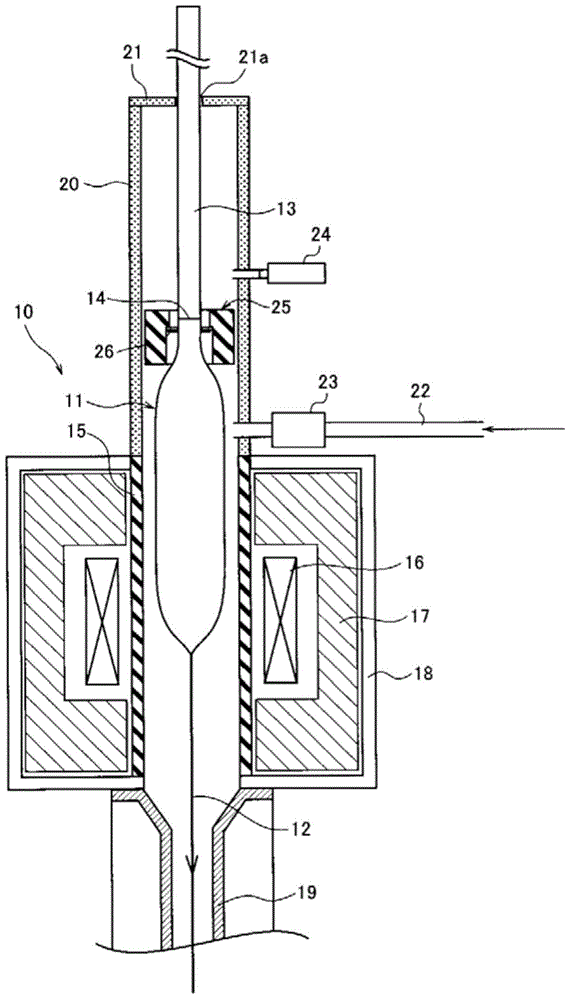

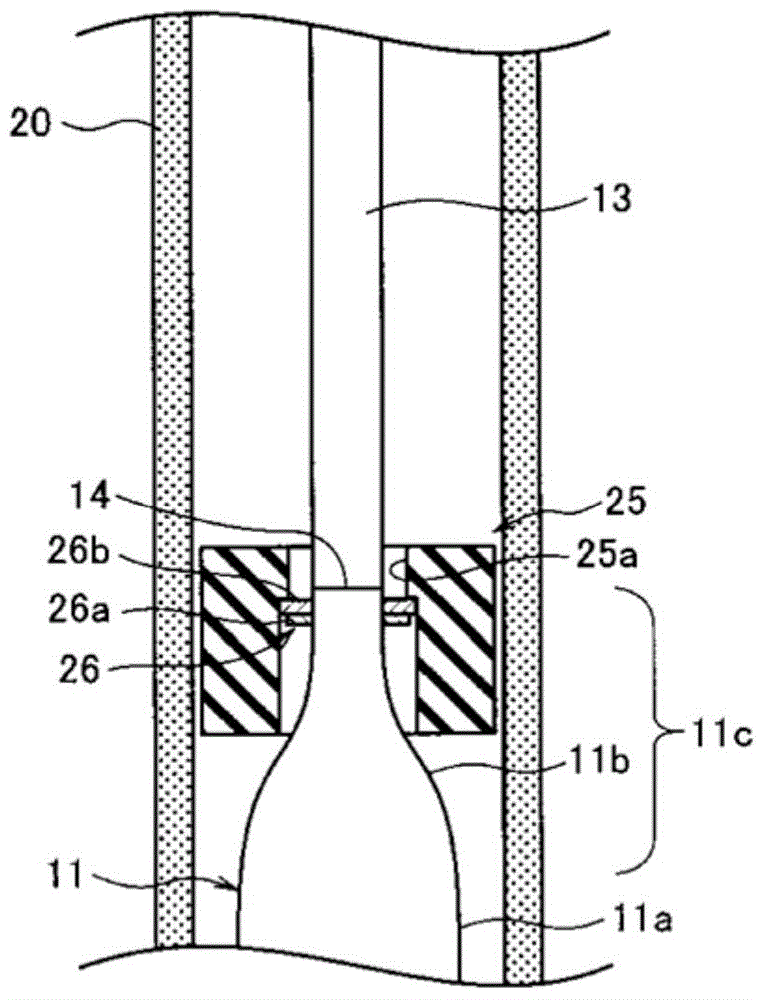

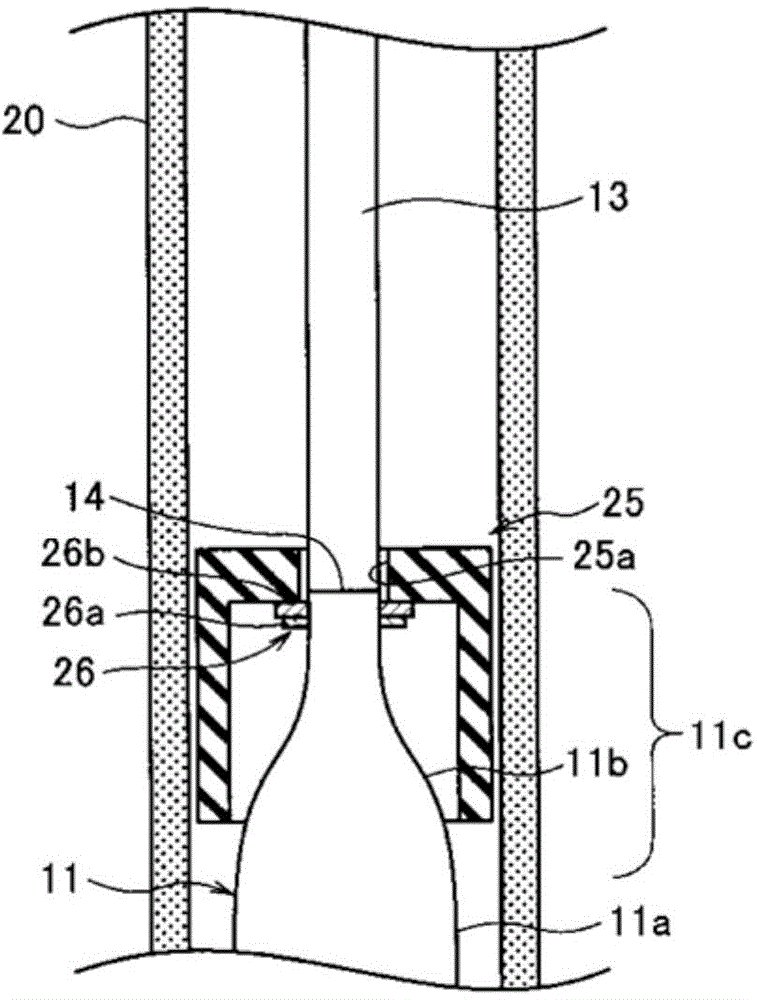

[0018] figure 1 It is a schematic diagram of the drawing furnace 10 used in the manufacturing method of the optical fiber of this invention. Hereinafter, a resistance furnace in which a core tube is heated by a heater will be described as an example, but the present invention can also be applied to an induction furnace in which a core tube is heated by induction by applying a high-frequency power supply to a winding.

[0019] The wire drawing furnace 10 is composed of a furnace housing 18 , a lower chamber 19 , and an upper chamber 20 . The furnace core tube 15 is formed in a cylindrical shape at the center of the furnace housing 18 and communicates with the lower chamber 19 and the upper chamber 20 . The furnace core tube 15 is made of carbon, and a glass base material 11 for an optical fiber (hereinafter referred to as a glass base material) is inserted into the furnace core tube 15 through the upper chamber 20 .

[0020] The upper chamber 20 has, for example, an inner dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com