Damper for furniture

A technology of buffers and furniture, applied in the field of buffers for folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

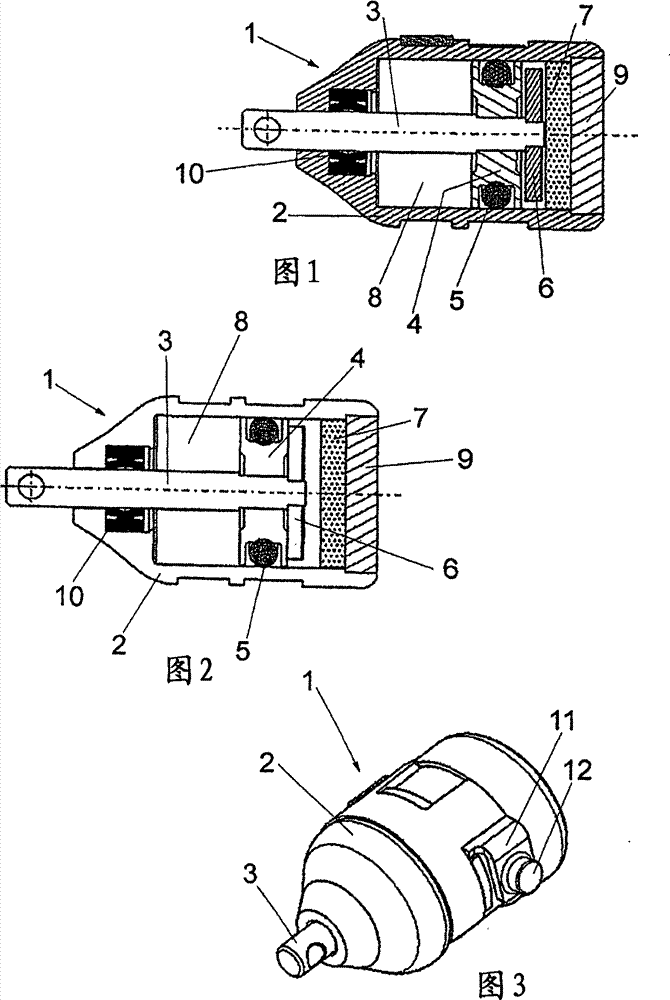

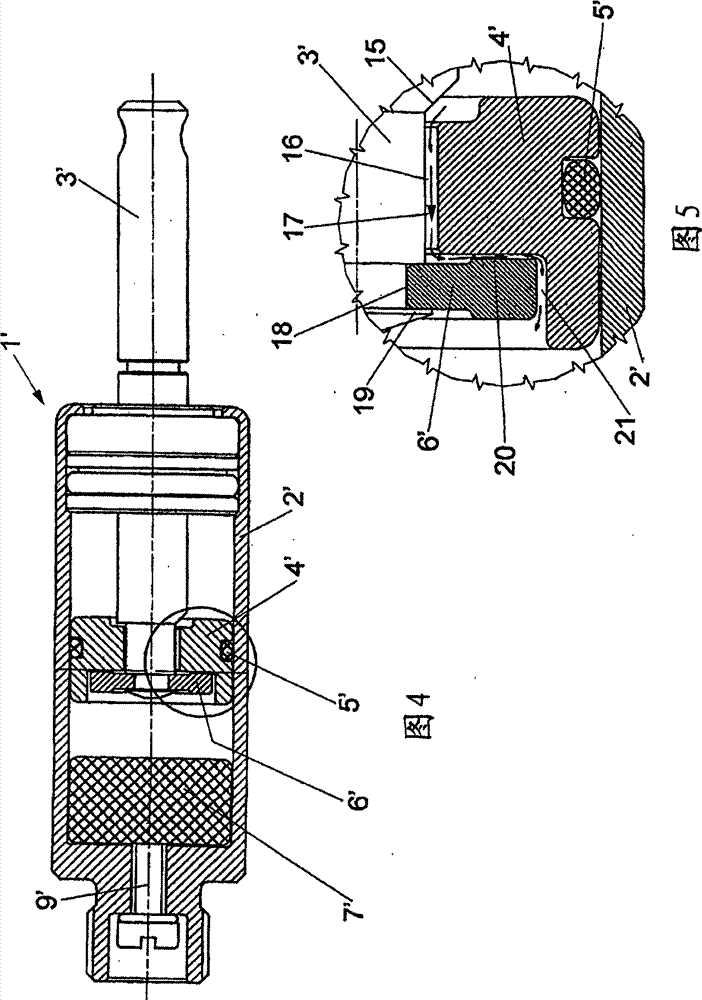

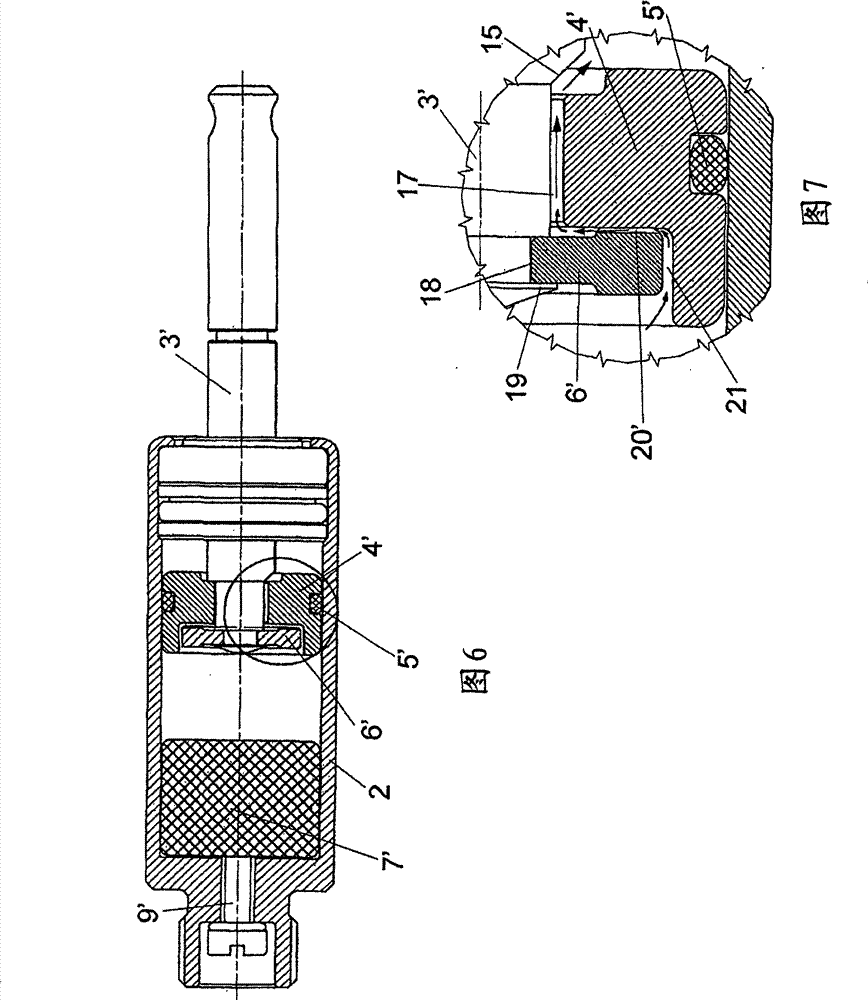

[0033] A pull-out damper 1 comprises a housing 2 and a cylindrical interior, in which a piston 4 is displaceably guided and held on a piston rod 3 . A sealing ring 5 , which bears against the inner wall of the housing 2 , is held in a groove on the outer circumference of the piston 4 .

[0034] A plate 6 is secured to one end of the piston rod 3 adjacent to the piston 4 . The above-mentioned piston 4 can move slightly axially on the piston rod 3, so that the distance between the plate 6 and the piston 4 can be changed.

[0035] An elastic foam material 7 is arranged adjacent to the plate 6 on the pressure-free side of the housing 2 and ensures a certain volume compensation when the piston rod 3 is drawn in and out of the housing. A fluid-filled interior 8 is provided on the opposite side of the piston 4 . Furthermore, the housing 2 is closed by a housing cover 9 . On the side opposite the cover 9 , the piston rod 3 is led out of the housing 2 in a sealing-tight manner via a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com