Valve for controlling fluid

A technology for controlling fluids and valve housings, applied to fuel injection devices with piezoelectric elements or magnetostrictive elements, engine components, machines/engines, etc., can solve disadvantages and other problems, and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

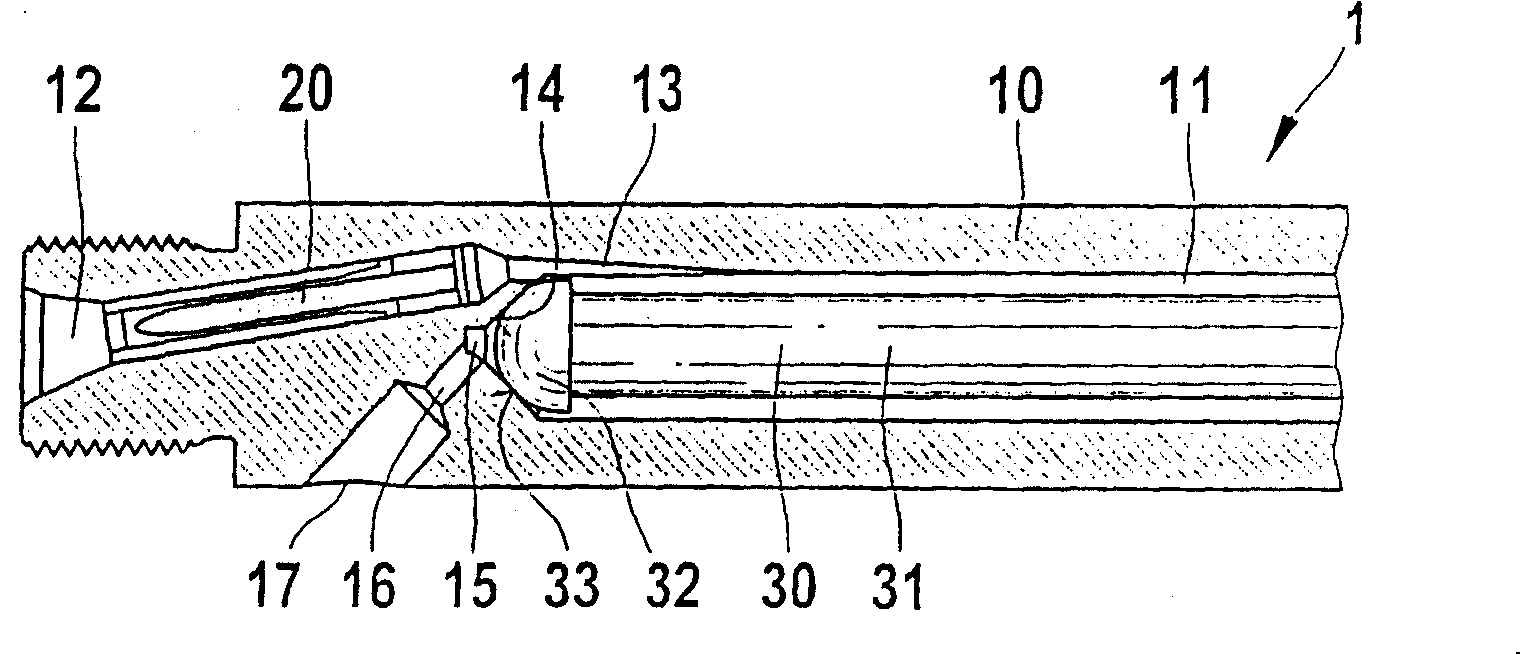

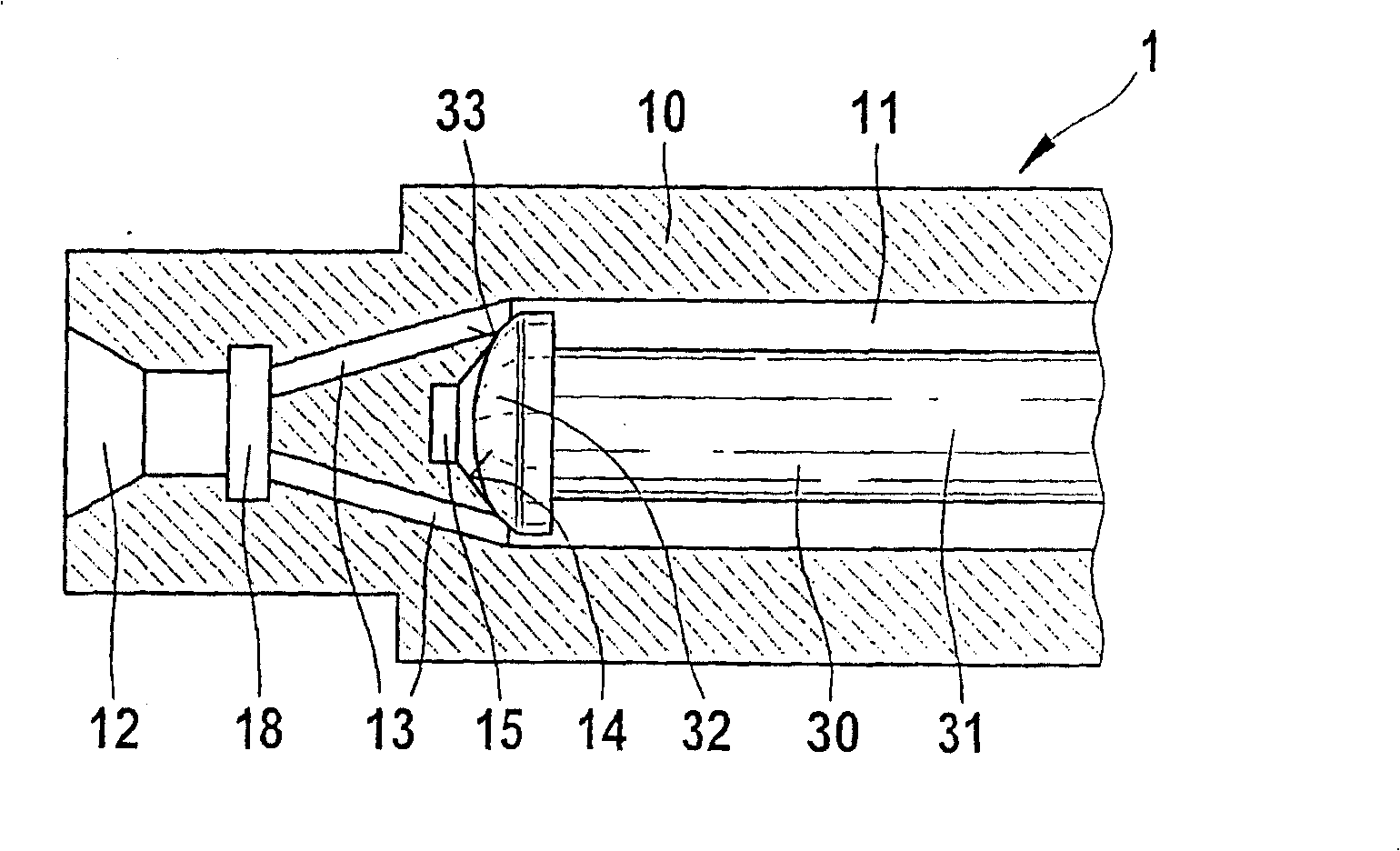

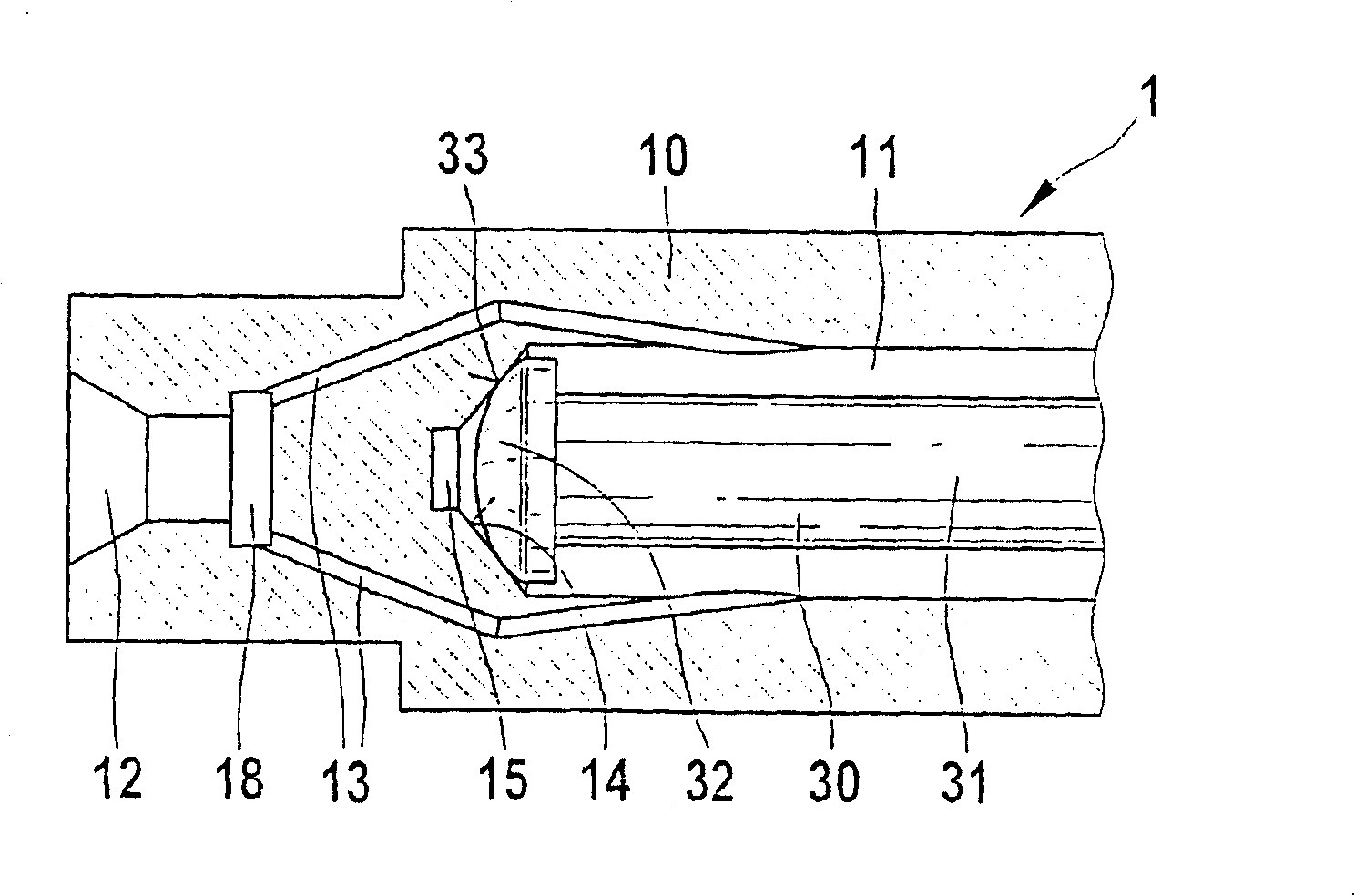

[0019] figure 1 Shown is a valve 1 for controlling a fluid, in particular diesel fuel, which is part of a common rail injector.

[0020] The valve 1 has a valve housing 10 in which extends in the longitudinal direction a pressure bore which forms an actuator chamber 11 . An actuator 30 is supported in the actuator chamber 11 and has a support 31 and an actuator head 32 . The actuator chamber 11 is sealed at its one end against a cable gland 17 by means of a conical seal. The conical seal is formed by means of a conical surface 14 at the end of the actuator chamber 11 and an annular sealing surface 33 corresponding to the conical surface on the actuator top 32 .

[0021] The valve housing 10 also has a high-pressure inlet 12 , which is connected to a high-pressure accumulator (not shown here) for liquid fuel. According to the prior art, fuel under high pressure is supplied laterally to the actuator chamber 11 of the valve housing 10 via an inlet opening 13 . Here, it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com