Method for bending metal wire comb-like form binding element

A technology of metal wire and components, applied in the direction of binding, application, folders, etc., to achieve the effect of stabilizing the printing material and avoiding lateral force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

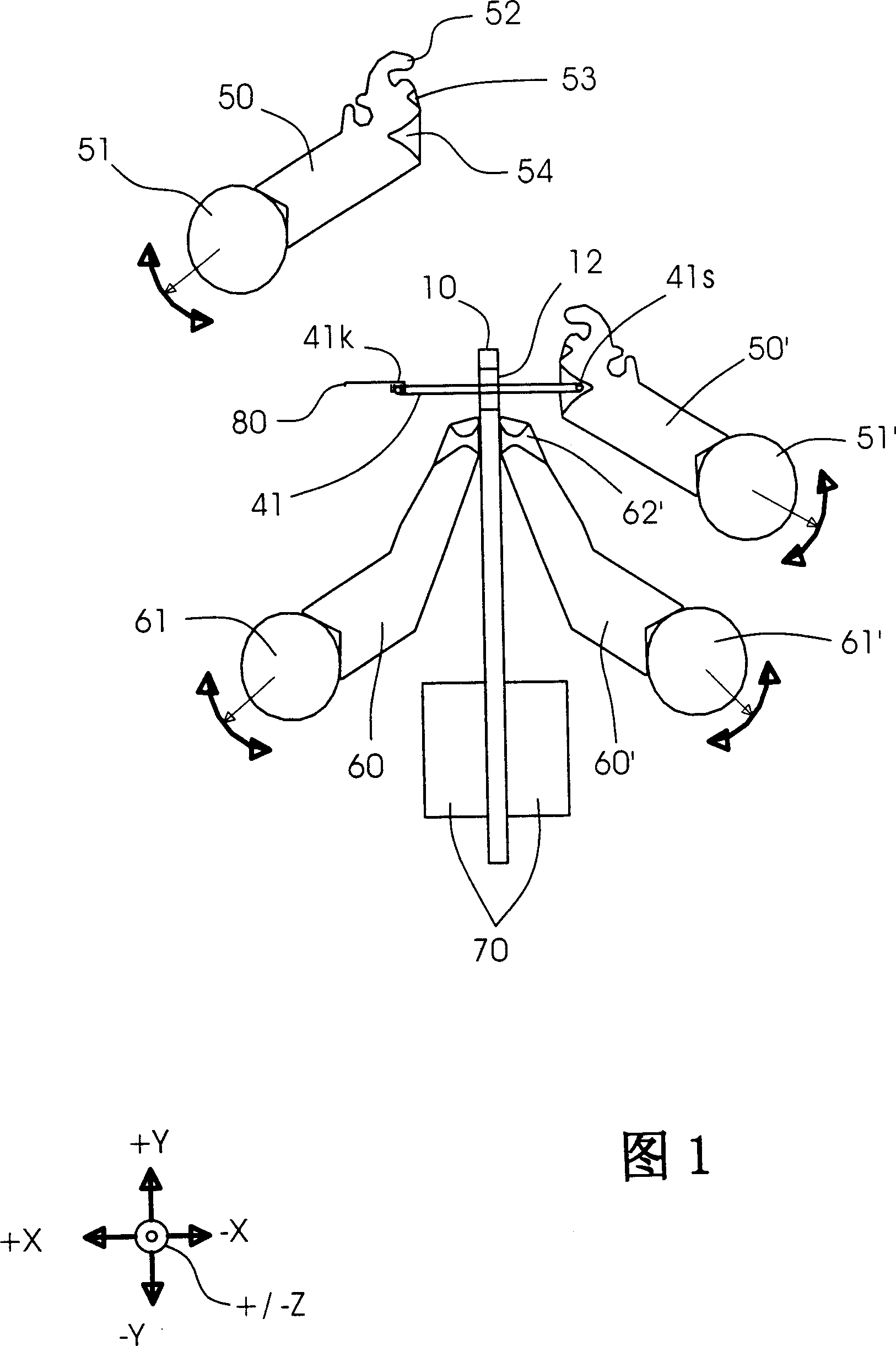

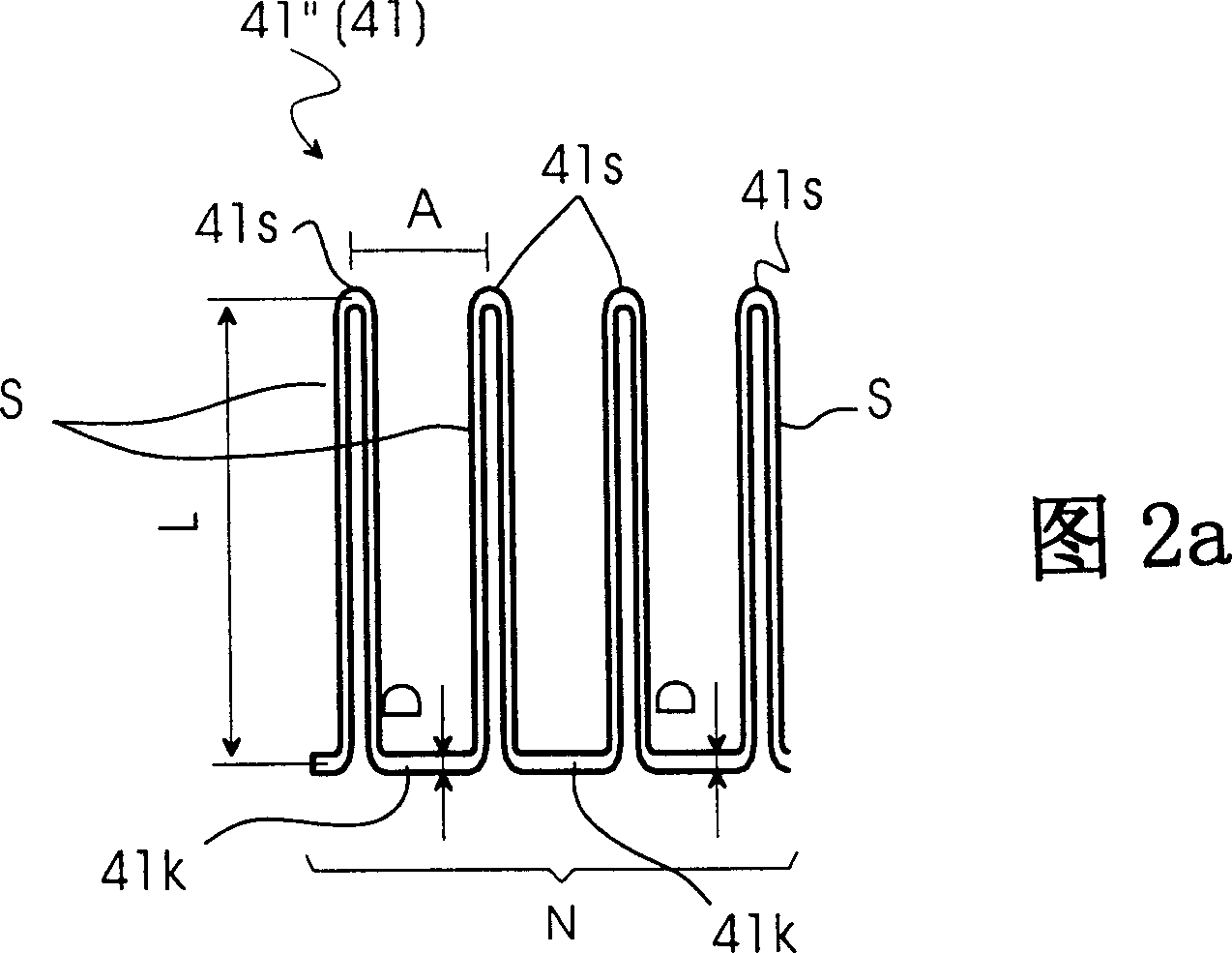

[0044] Fig. 1 shows the overall structure of the device of the present invention, and for simplicity of description, only the main components of the present invention are shown or described. Other drives and / or guides and electrical / electronic circuits which are generally known and required for the operation of the device are not shown here or are only described in general form.

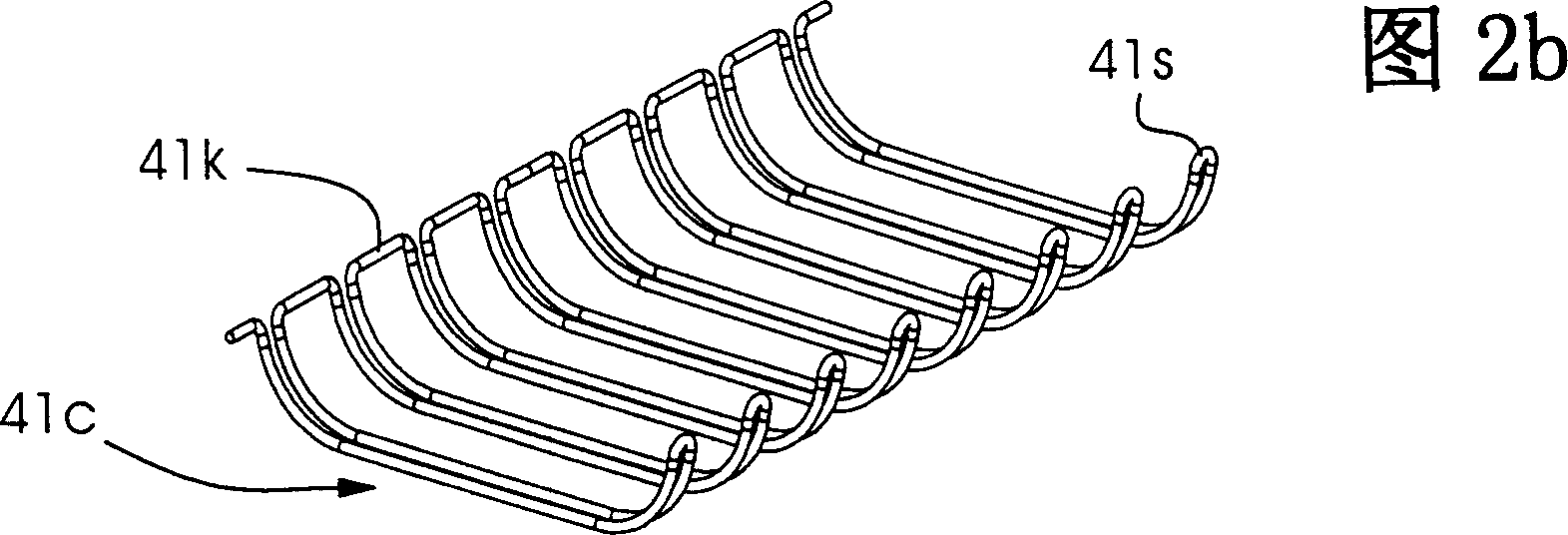

[0045] The device of the present invention mainly includes a pair of C-shaped shapers 50, 50' and a pair of O-shaped shapers. Shape 41c, the O-shaped shaper bends the return-bent wire binding element 41 bent into a C-shape 41c into a closed O-shape 41o for loosely binding the sheet-like printing materials 11 into a booklet 10 .

[0046] The sheet-shaped printing material 11 has a plurality of holes 12, and the outer edges of the holes of a stack of sheet-shaped printing materials 11 are identical, one above the other to form a substantially straight path for the return S of the flat wire binding elem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com