Side-by-side type rotary piston internal combustion engine

A technology for rotating pistons and internal combustion engines, applied to internal combustion piston engines, combustion engines, mechanical equipment, etc., can solve the problems of increased piston and cylinder liner wear, vibration and noise of the whole machine, unfavorable mixture gas formation, combustion and emission reduction, and difficult to use Air flow kinetic energy and other issues to achieve the effect of improving battery life, simple structure, and increased exhaust time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] When implementing, the maximum output torque or maximum output power and maximum speed should be determined first, and a certain type of reciprocating piston internal combustion engine can also be selected to design based on its main parameters. Specific steps are as follows:

[0029] 1. See Figure 4 , calculate the minimum shaft diameter of the main shaft 1 according to the maximum output torque or maximum output power and maximum speed, and draw the structural sketch of the shaft 1 according to the load on the shaft 1.

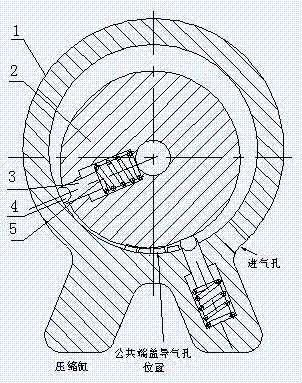

[0030] 2. See figure 1 , according to the maximum output torque and the maximum pressure of gas combustion in the cylinder, determine the maximum lift of the cam-shaped piston 2 curve and the average area of the protruding part of the piston slide 3. Determine the minimum wall thickness for cylinder block 1.

[0031] 3. See figure 1 , in order to achieve the maximum output torque requirement, how to make the cylinder volume to the minimum is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com