Automated large outer diameter preform tipping process and resulting glass preform

A glass preform and preform technology, applied in glass manufacturing equipment, manufacturing tools, glass production, etc., can solve problems such as troubled metal wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0060] The following examples are included to more clearly demonstrate the general nature of the invention. These examples are examples of the invention and do not limit the invention.

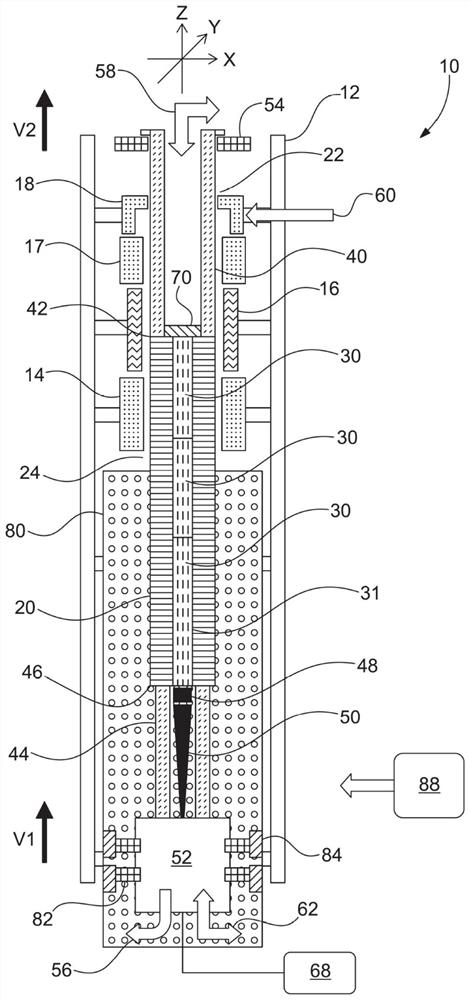

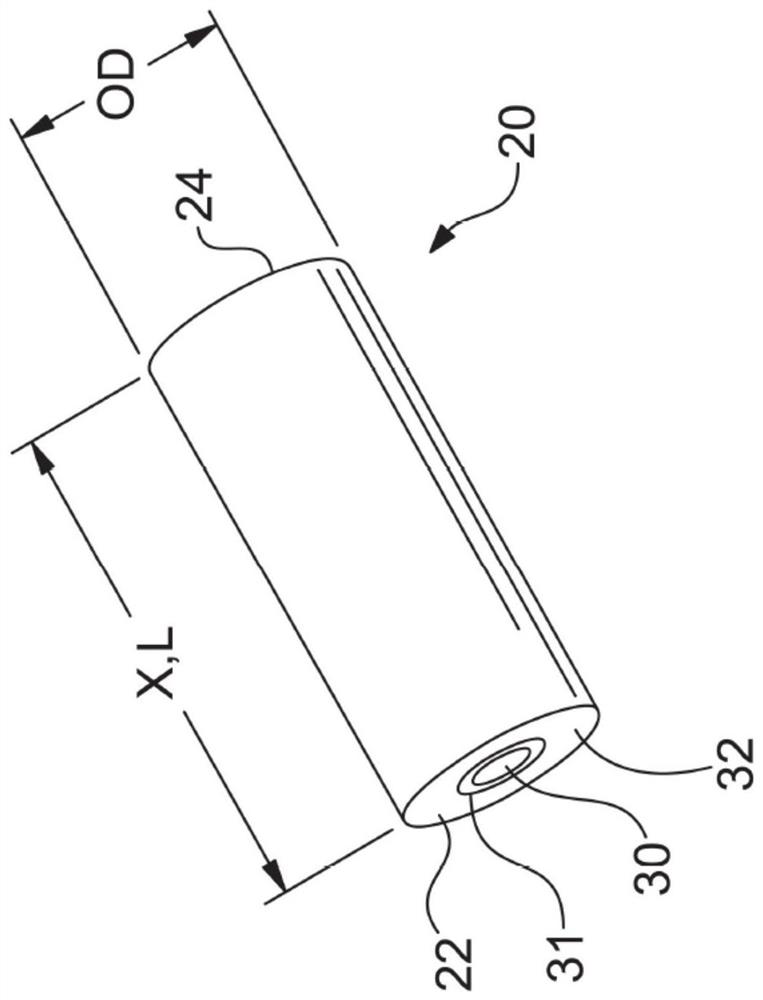

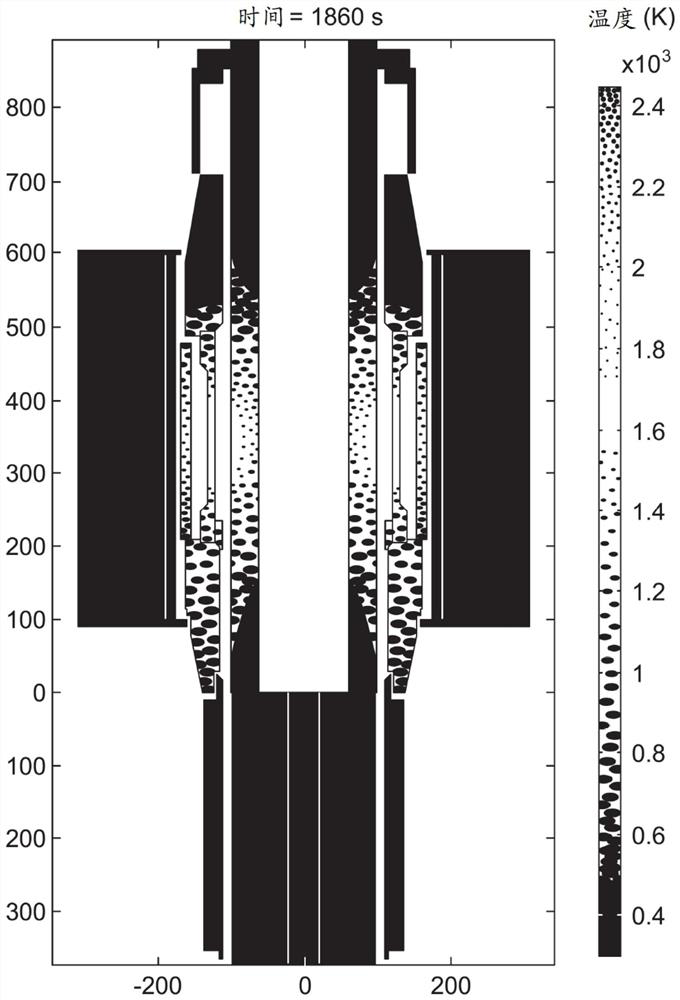

[0061] FEM (Finite Element Modeling) is used to form a process recipe via simulation that combines the movement of the cylinder with the heating rate of the oven to avoid thermal shock to the cylinder and to collapse the cylinder at the right time the temperature required for shrinkage ends. With these simulations, such as Figure 3A , Figure 3B , Figure 3C and Figure 3D As shown, the recipe is identified as standard procedure to preheat the top of the cladding 32 and initiate collapse of the interface between the cladding 32 and the mandrel 30 (ie, closing the gap 31 of the glass body 20). These four plots are snapshots of four typical moments in the simulation, which only attempt to show the warm-up phase (A-B), the dwell time in the center of the heater, and the progressive upward c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com