Dual-body track fixing device

A fixing device and track technology, applied in the direction of track system, transportation and packaging, load hanging components, etc., can solve the problems of affecting the strength of the contact surface between the base plate and the T-bolt, affecting the strength of the base, easy to loosen, etc. Maintenance cost, convenient installation, and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

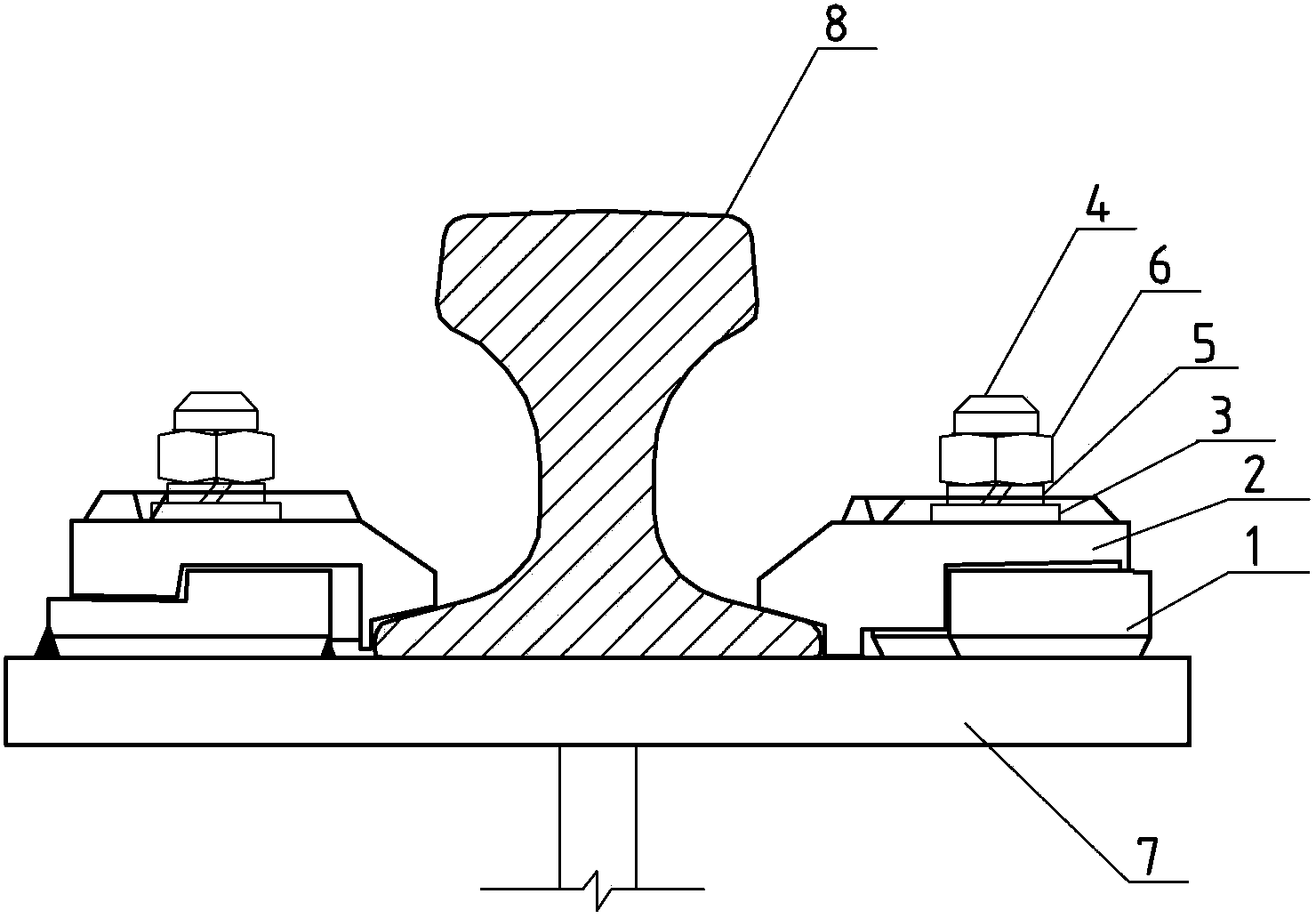

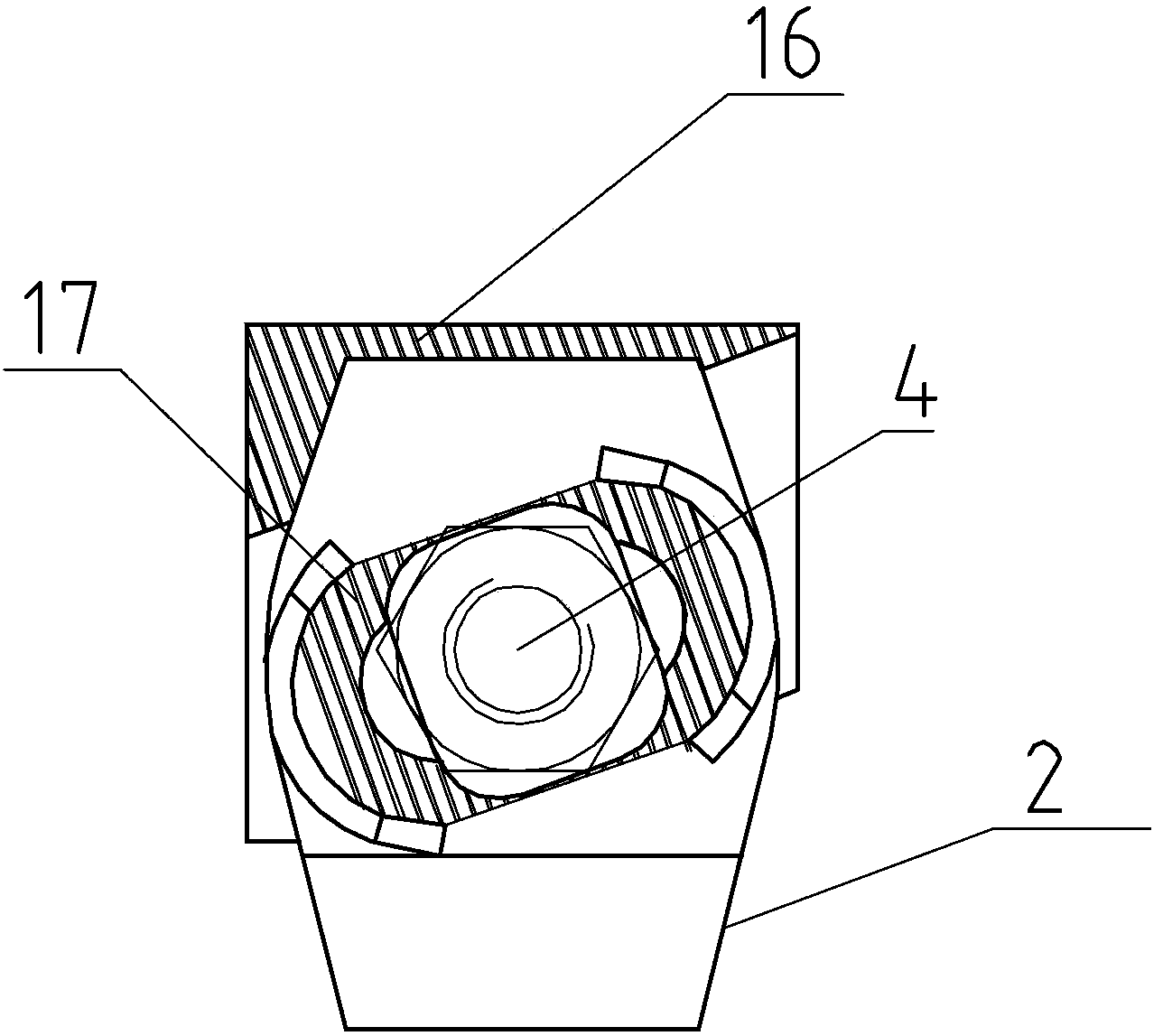

[0023] This embodiment is a two-body rail fixing device. The whole set of fixing devices is arranged on both sides of the upper flange rail 8 of the steel beam 7, and consists of a fixed base 1, an upper cover 2, a toothed backing plate 3, a bucket bolt 4, and a spring washer 5 , Nut 6, composition.

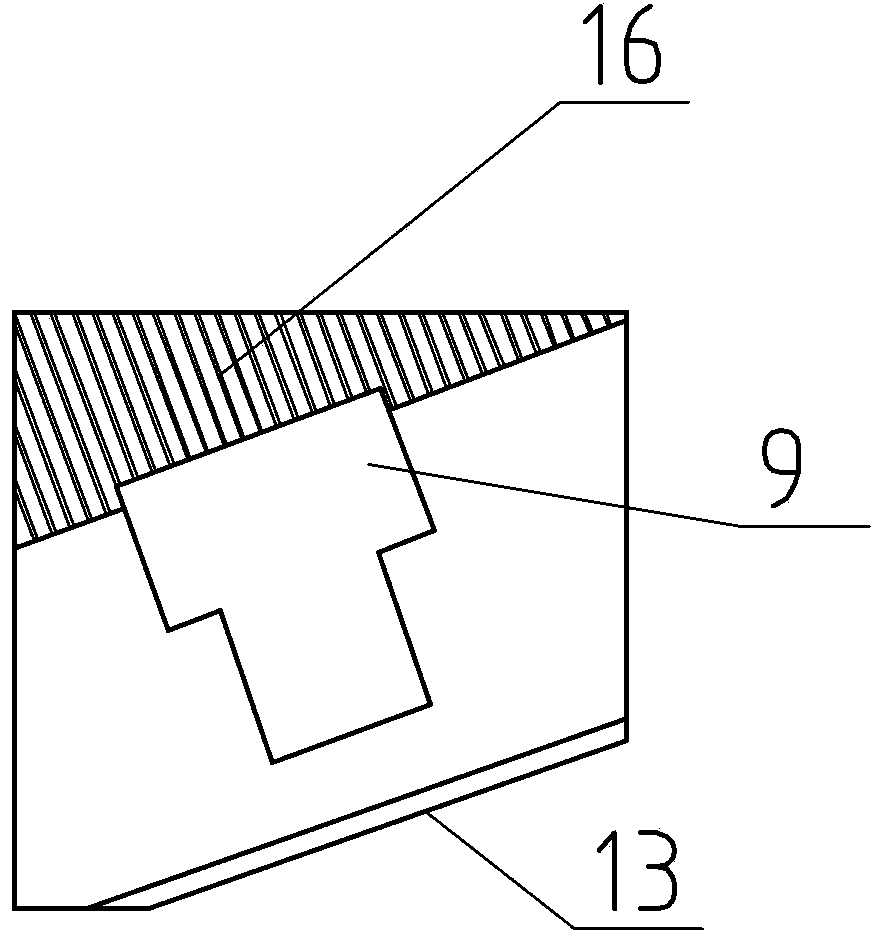

[0024] Two-body reinforced structure, the fixed base 1 is welded with the steel crane beam 7 on all sides, and there is a groove around the fixed base 1 when it is welded with the vehicle beam 7 to strengthen the welding strength and force strength. The middle part of the fixed base 1 has Two T-shaped openings are used to hang the bucket bolts 4, and the two sides of the hanging bolts in the T-shaped openings of the fixed base are bucket-shaped (the bottom is wide and the top is narrow), and has a slope; the lower part of the bucket bolts 4 and the fixed The contact part of the base 1 is bucket-shaped (wide at the bottom and narrow at the top) with a slope; the bucket-shaped bolt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com