A motorized viscous material dispenser

A dispenser, motorized technology for use in caulking guns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] For simplicity, the terms "upper", "lower", "front" and "rear" in the description of the invention are used to describe the interrelationship of the different parts and assemblies of an embodiment of the dispenser according to the invention. Those skilled in the art will recognize that the dispenser will generally be tipped, tipped and turned during use to suit the actual task being performed with the dispenser.

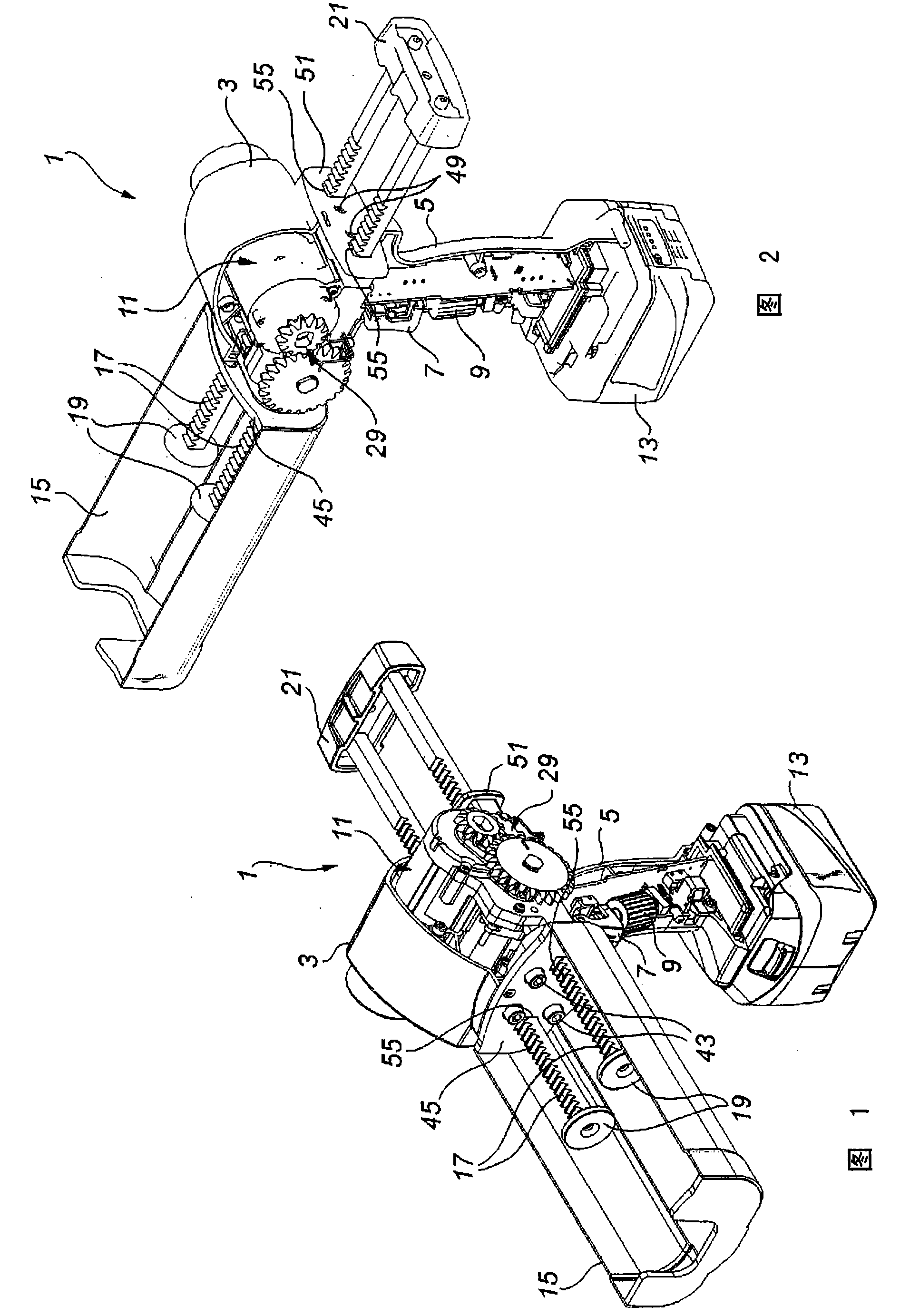

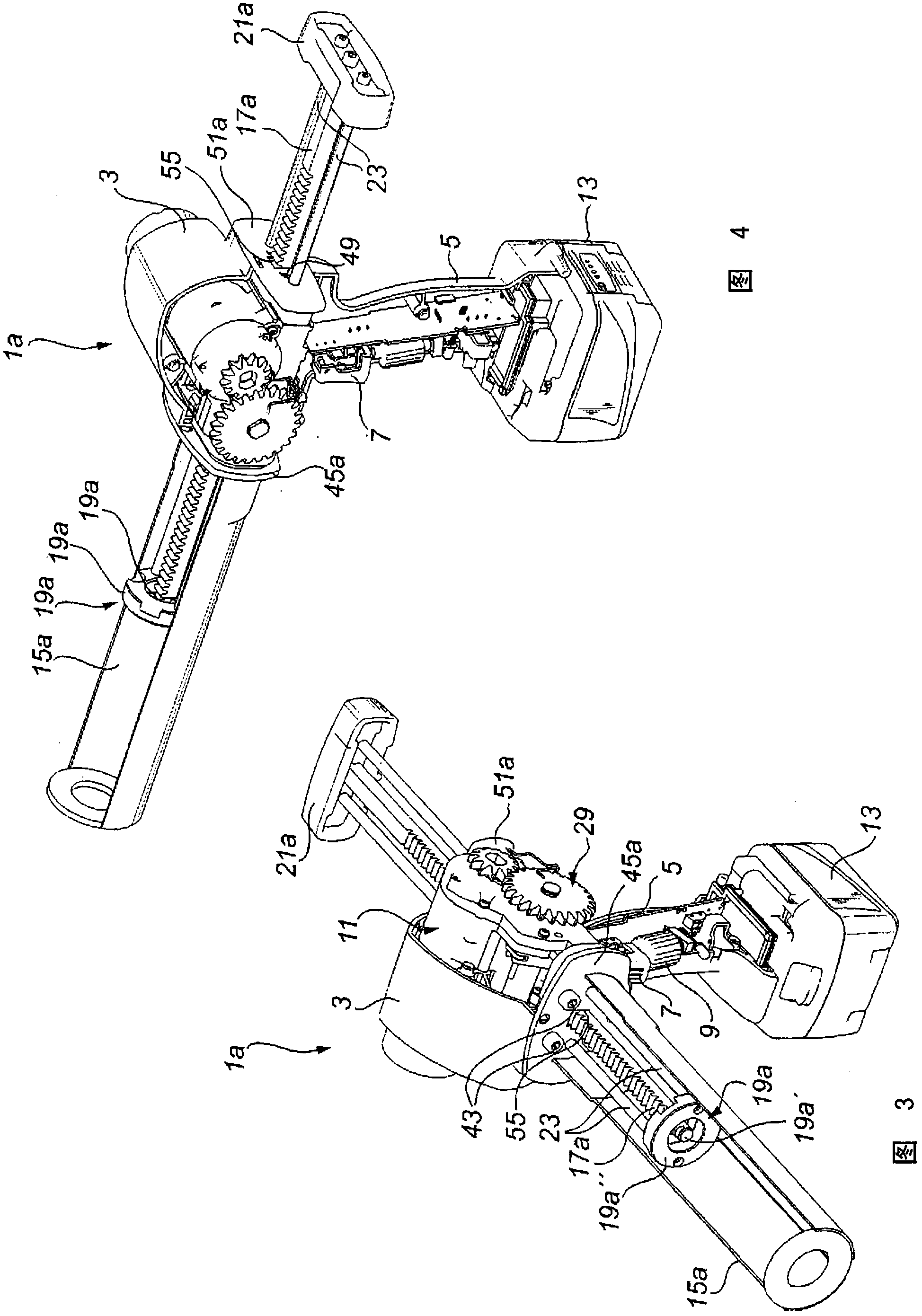

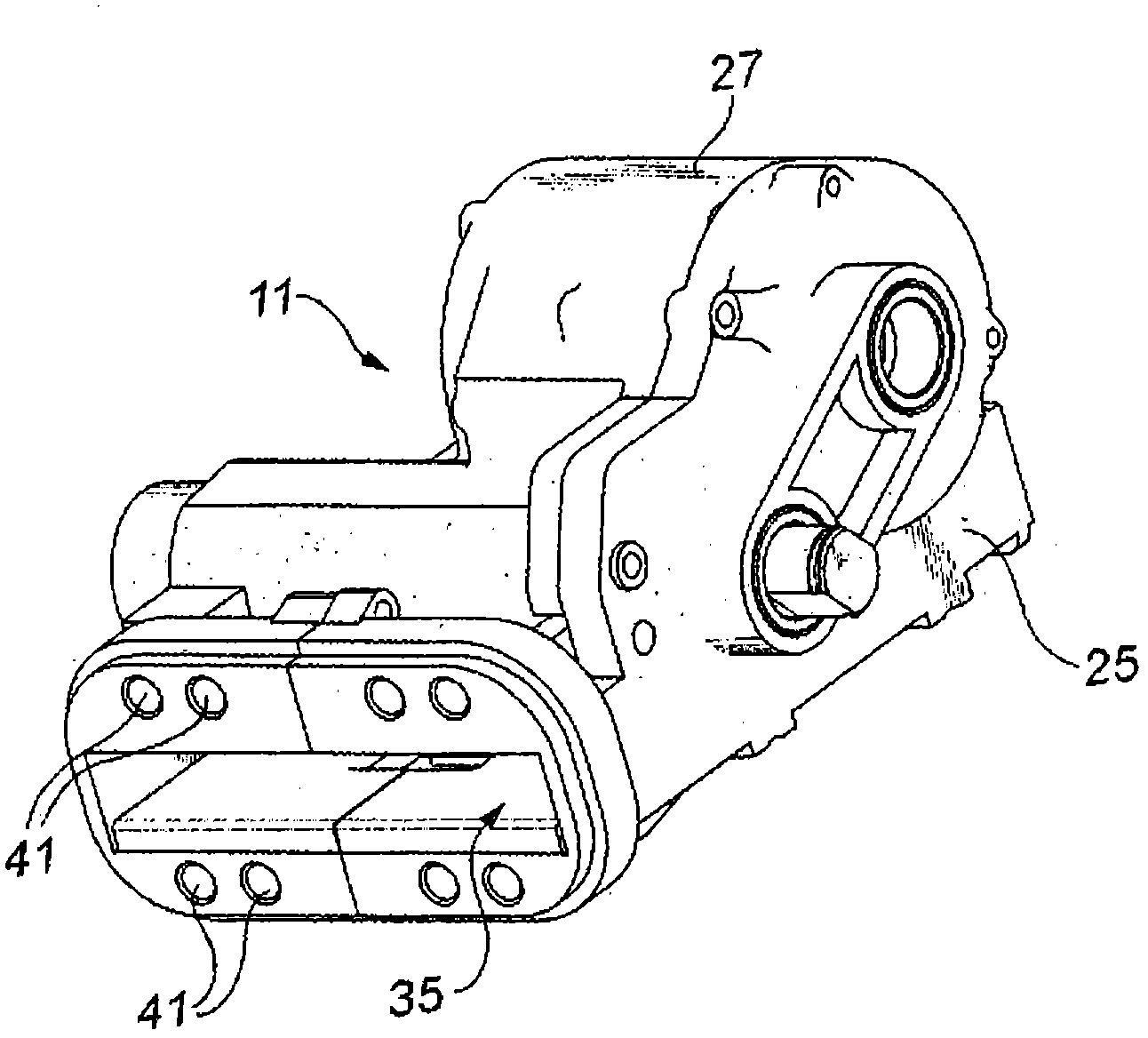

[0029] figure 1 and figure 2 An embodiment of such a motorized viscous material dispenser 1, commonly referred to as a caulking gun, is shown. The caulking gun comprises a housing 3, part of which has been left out to show the internal components, which provides a handle 5 to be grasped by the operator for operating the dispenser to dispense material. At the handle, the dispenser includes a trigger 7 and a speed control dial 9 . The housing 3 houses the drive unit 11, the components of which are also shown in Figure 5 , 6 , 9 in. Attached to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com