Patents

Literature

36results about How to "Guaranteed parallel movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

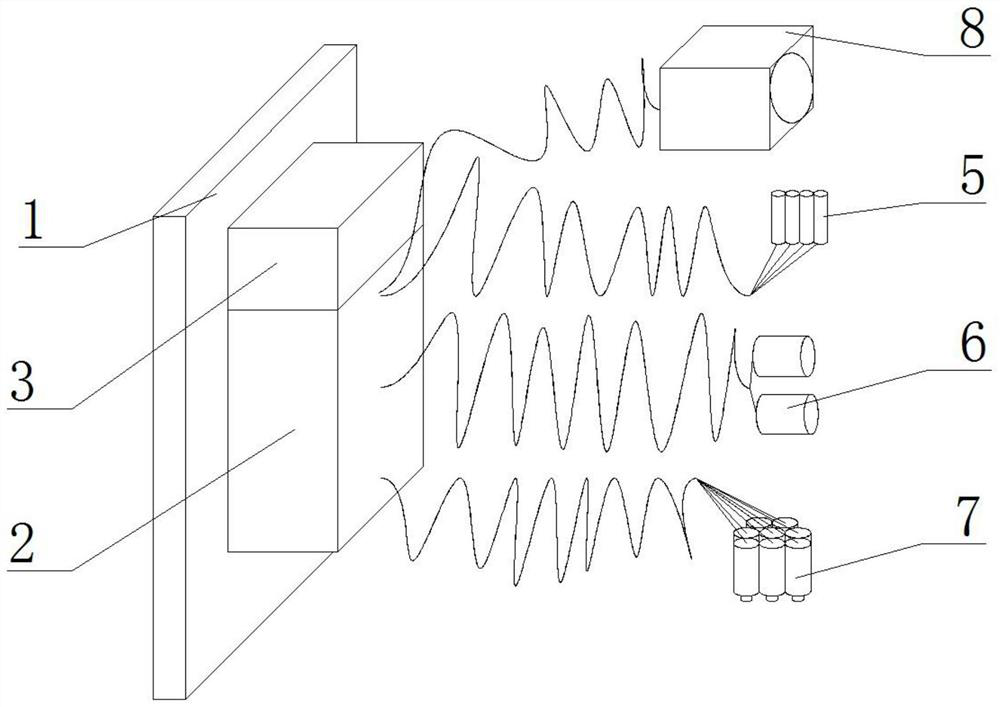

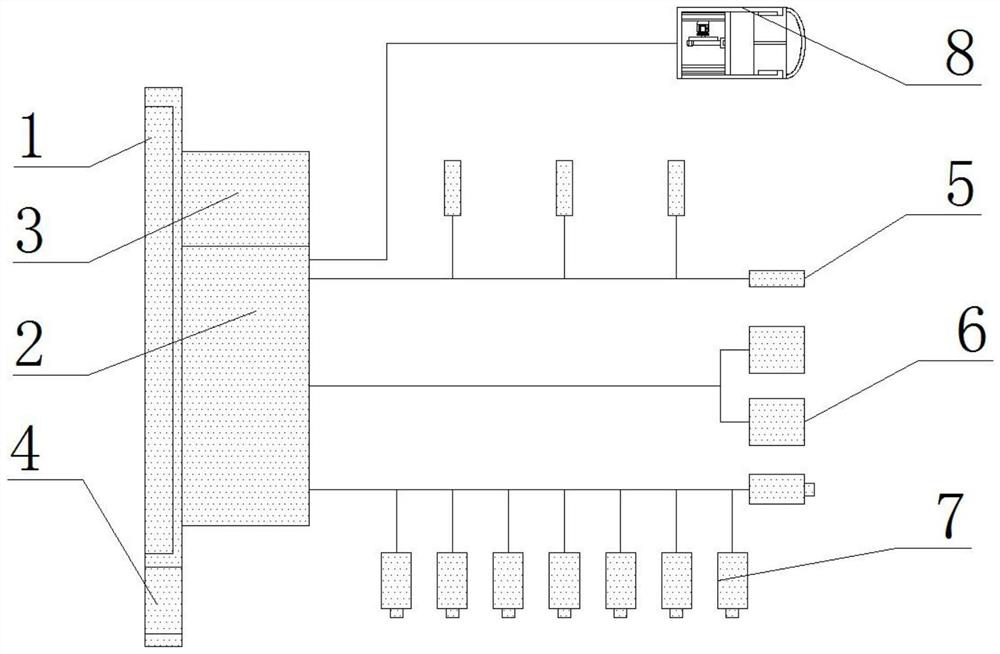

Wire-arranging mechanism of multi-head wire-rewinding machine and numerical control wire-arranging method

InactiveCN101863398AReduce distractionsReduce production capacityFilament handlingManufacturing cost reductionNumerical control

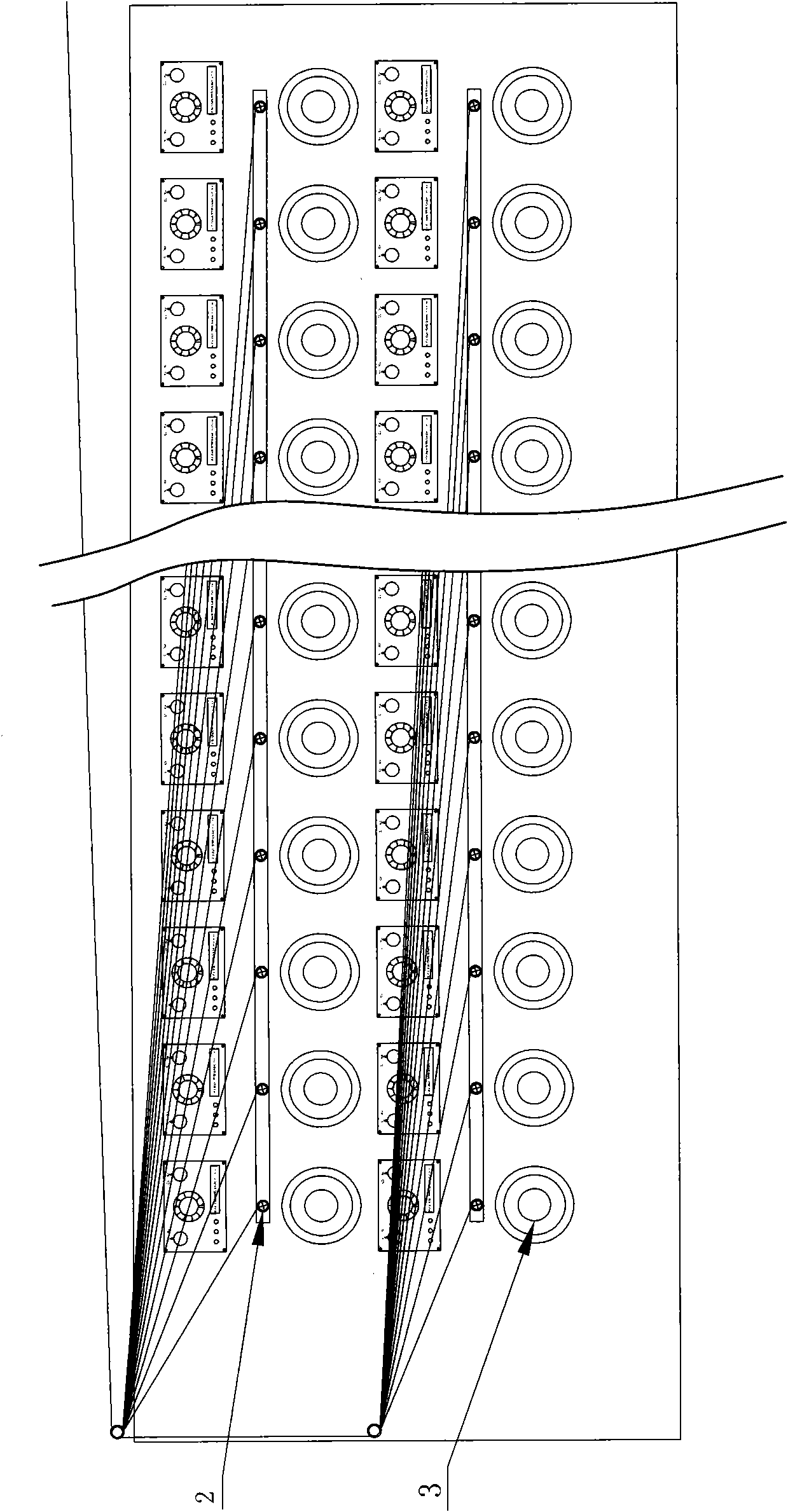

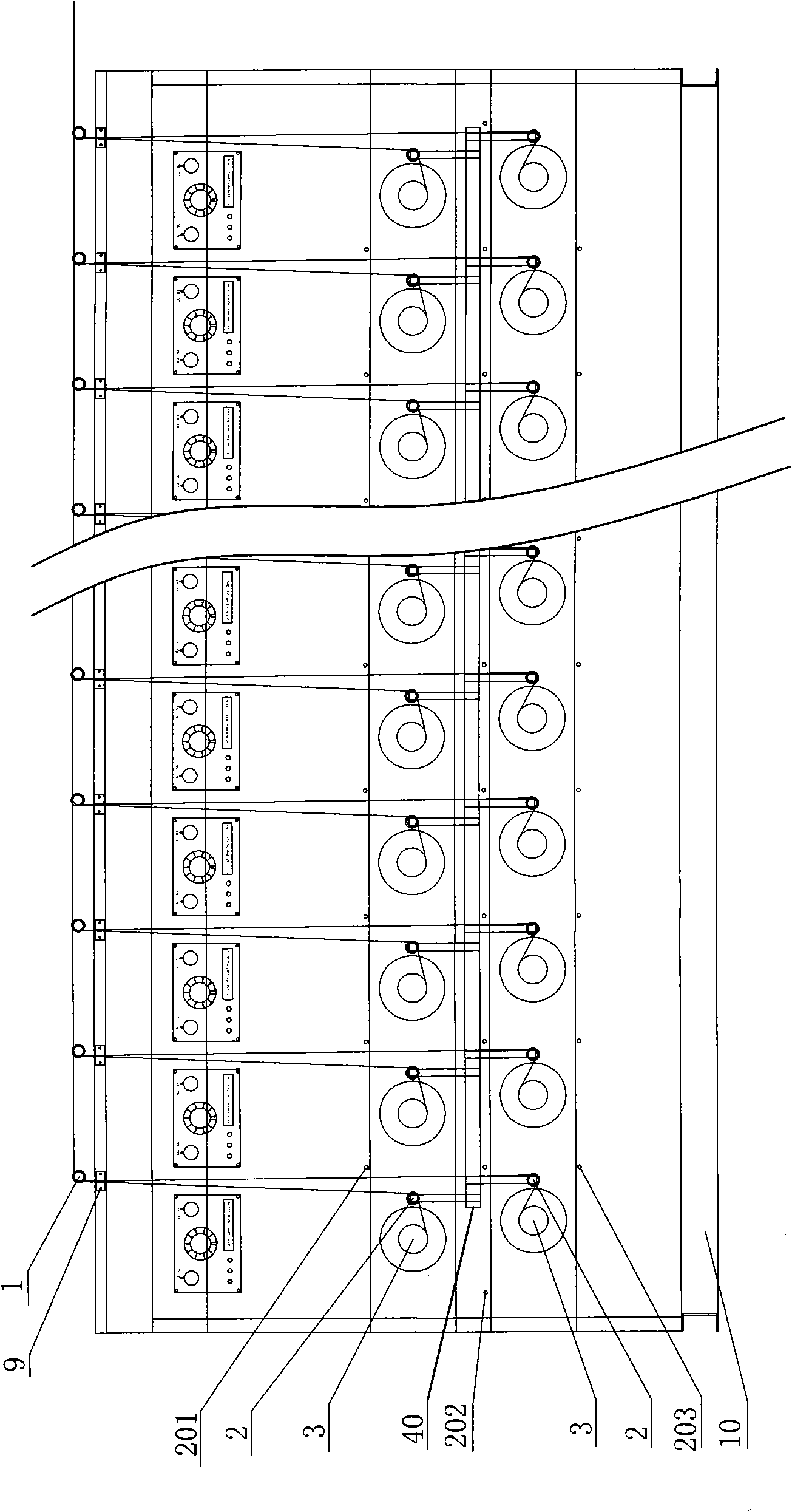

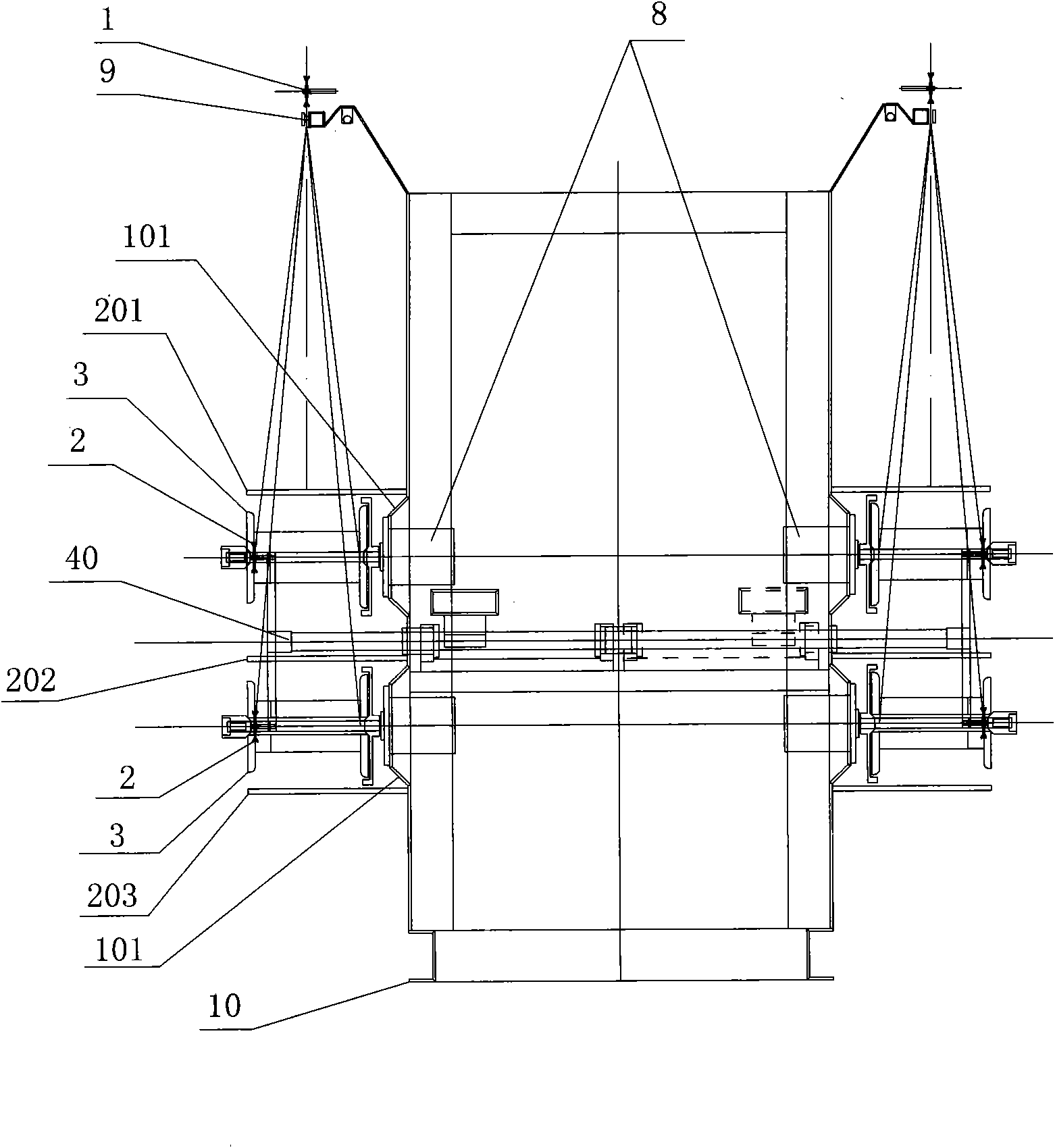

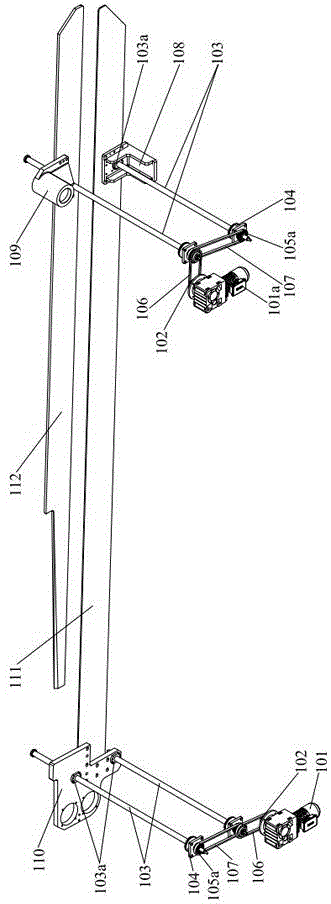

The invention relates to the field of wire-arranging technology of a multi-head wire-rewinding machine, in particular to a wire-arranging mechanism of the multi-head wire-rewinding machine and a numerical control wire-arranging method. The wire-arranging mechanism of the multi-head wire-rewinding machine comprises a stander, a PLC controller, a screw rod driving device, wire-arranging guide wheels, a reversing guide wheel and a wire-arranging guide wheel driving device, wherein the wire-arranging guide wheel driving device is connected with the wire-arranging guide wheels; the screw rod driving device comprises a screw rod, a screw rod nut, an approach switch, two screw rod bearing seats, two synchronous belt pulleys, a synchronous belt and a constant speed motor, wherein the screw rod nut is connected with the wire-arranging guide wheel driving device; the PLC controller is connected with the approach switch and the constant speed motor; and the PLC controller is provided with a forward rotation monitoring timer, a reverse rotating monitoring timer, a millisecond-level reversing timer and a speed increasing and reducing timer. The invention not only reduces the interference amongwires and the production accidents and improves the wire-arranging quality and finished product wire quality, but also simplifies the structure, is easy for operation and reduces the manufacturing and maintaining costs.

Owner:东莞市康汇聚线材科技有限公司

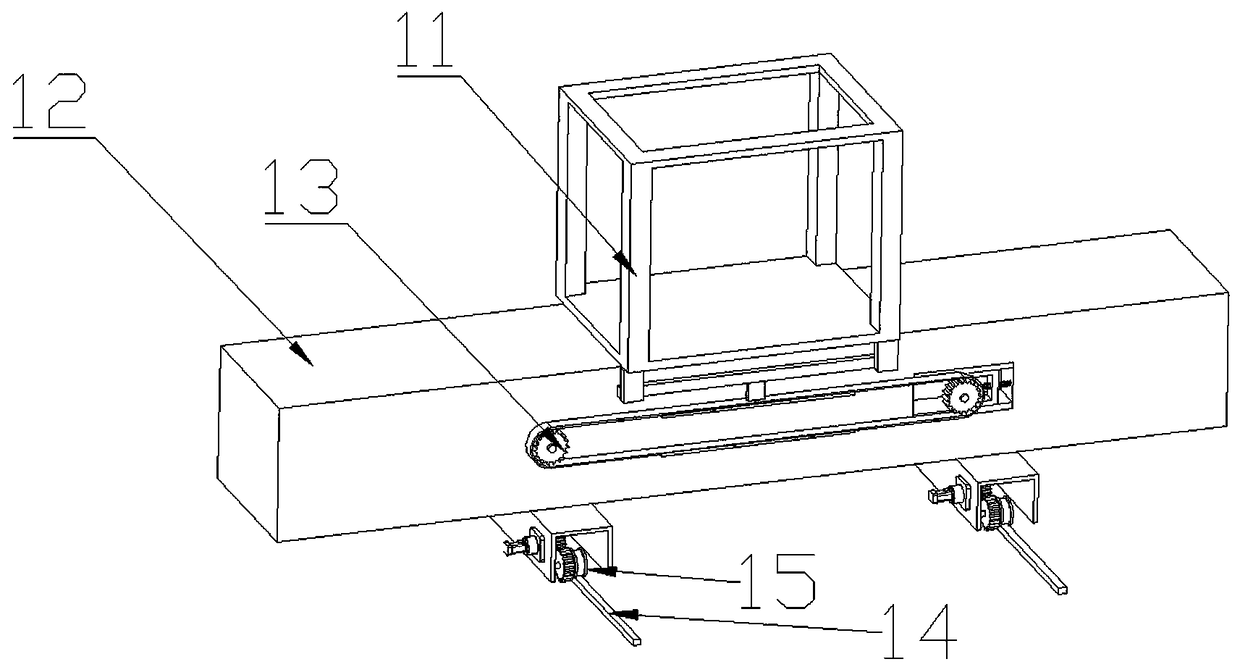

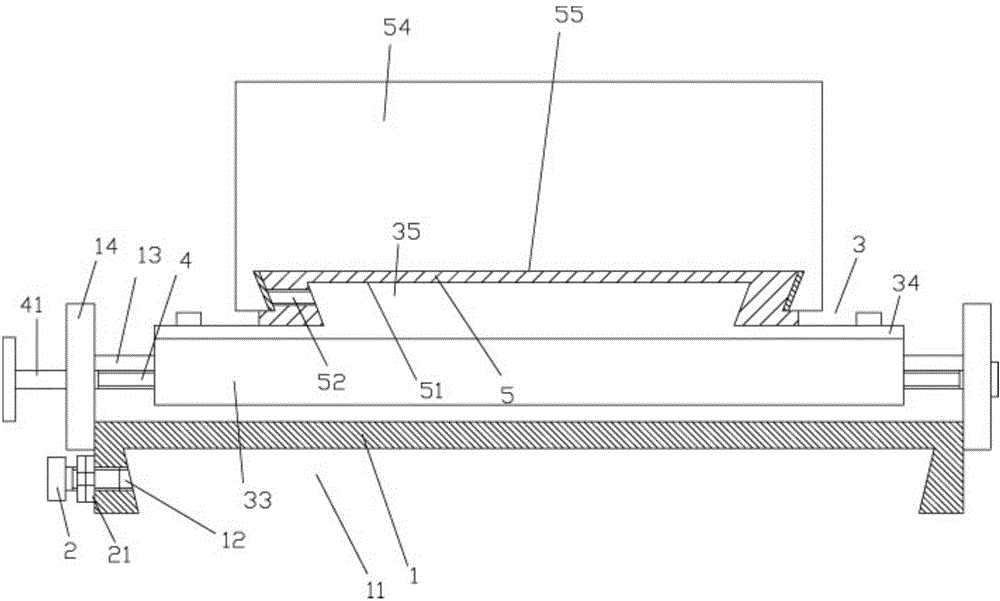

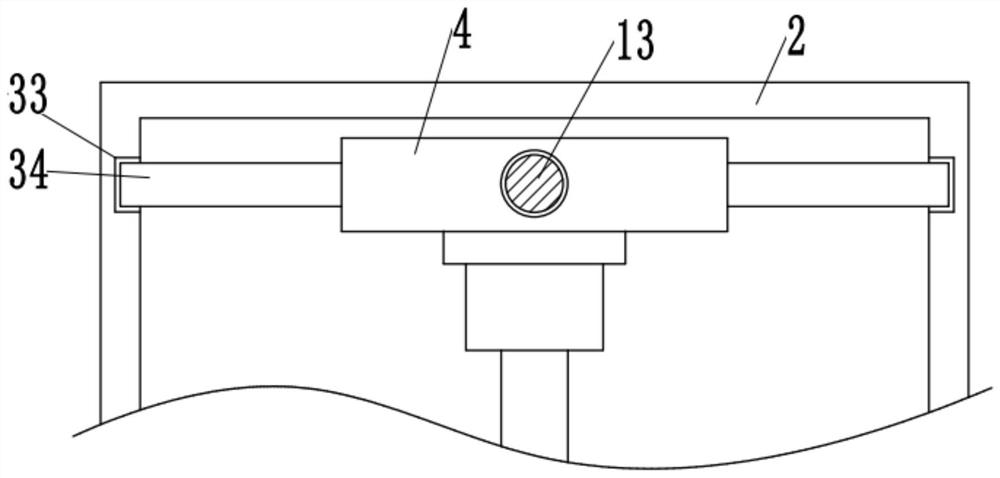

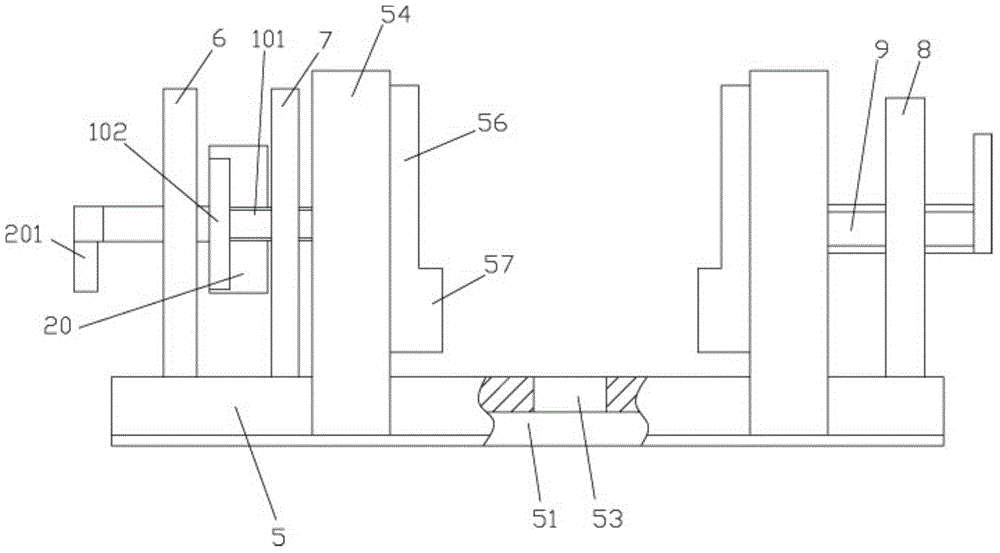

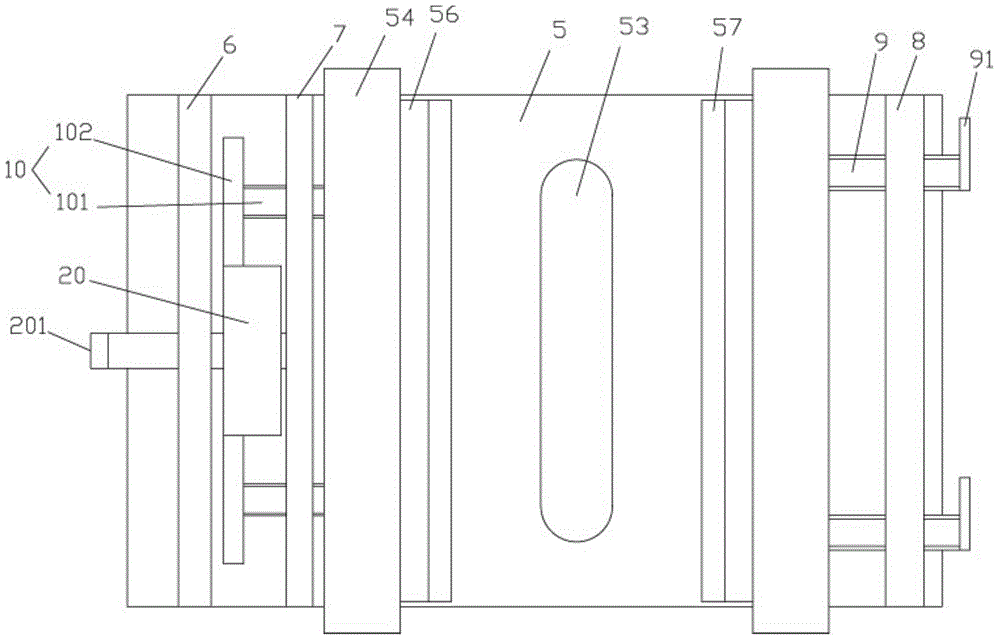

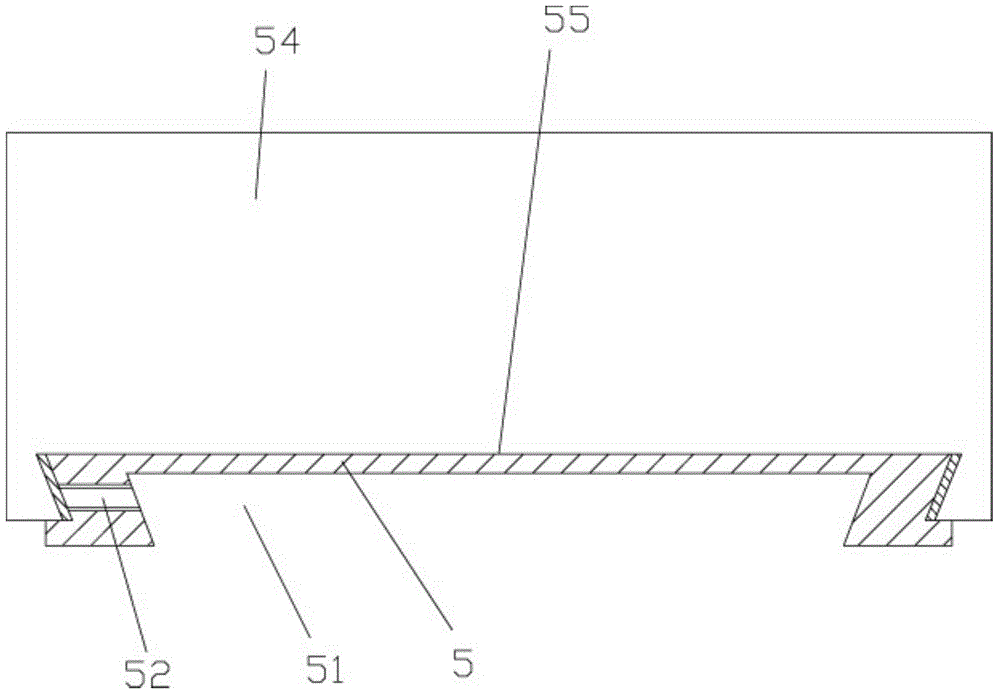

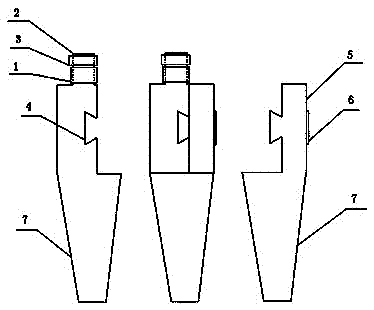

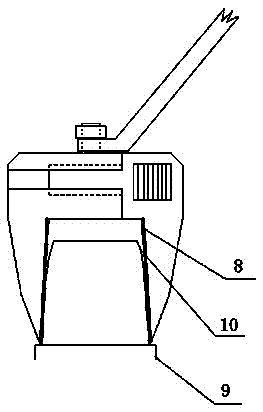

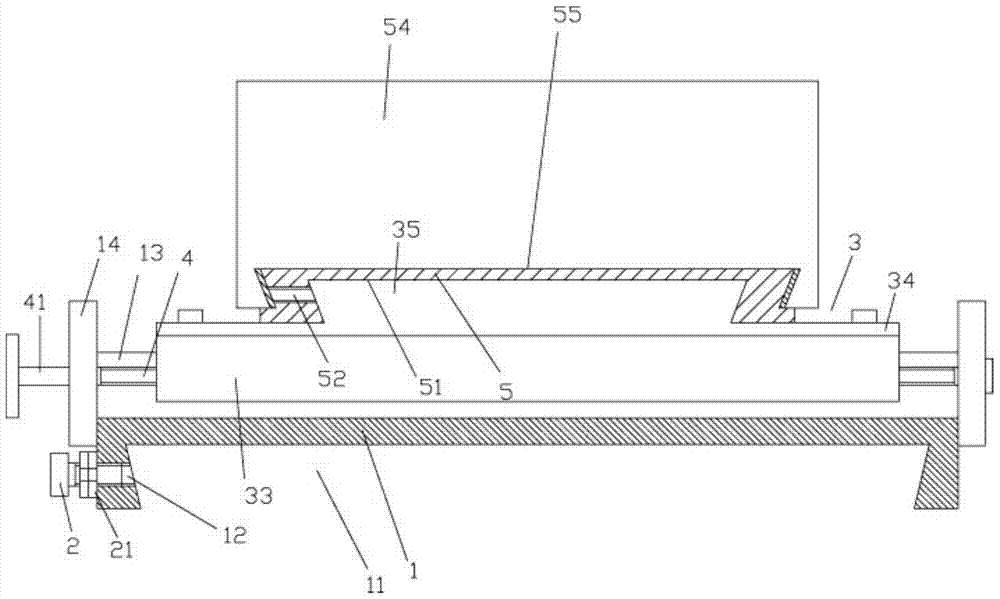

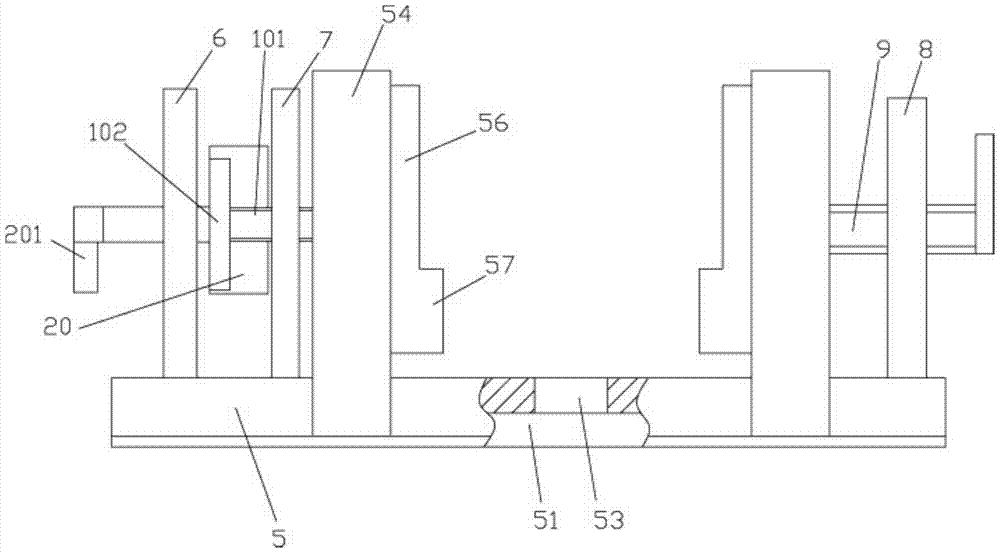

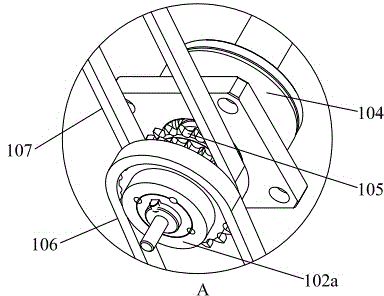

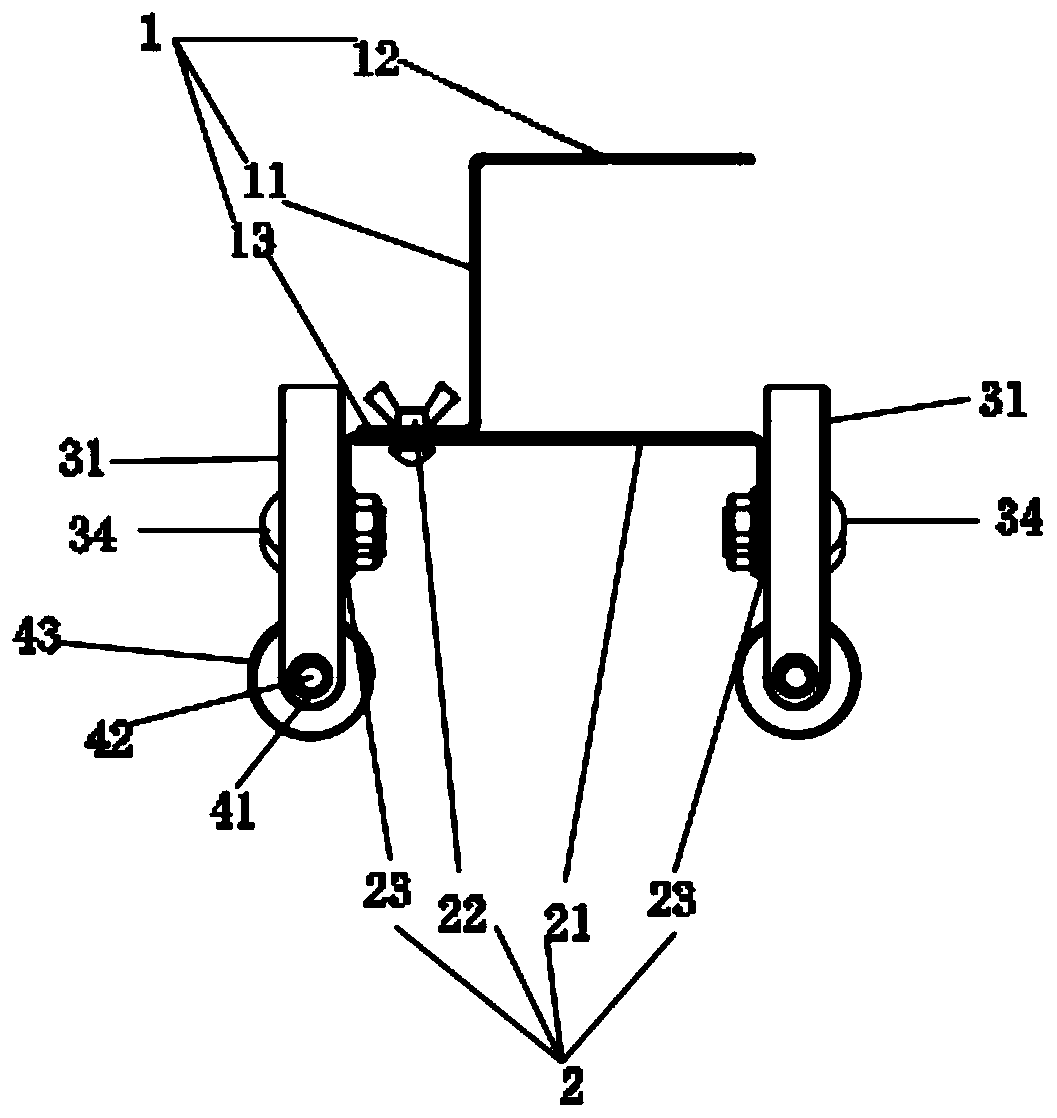

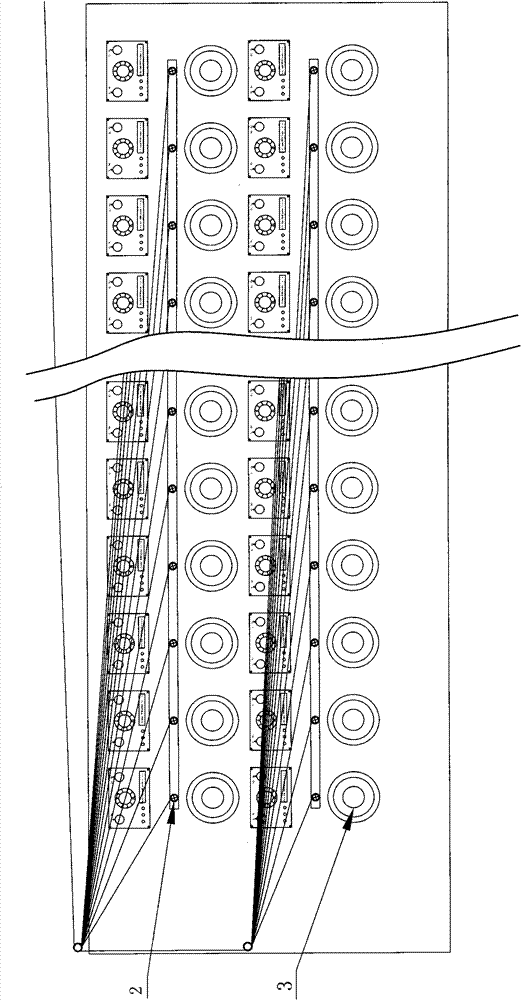

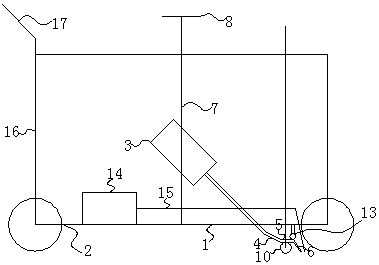

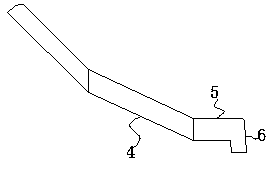

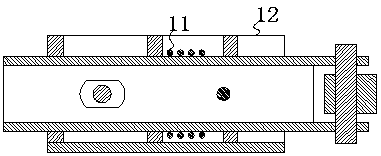

Coiling machine and method for glass reinforced plastic pipe

PendingCN108544769AWind evenlyFlexible adjustment of horizontal distanceTubular articlesYarnEngineering

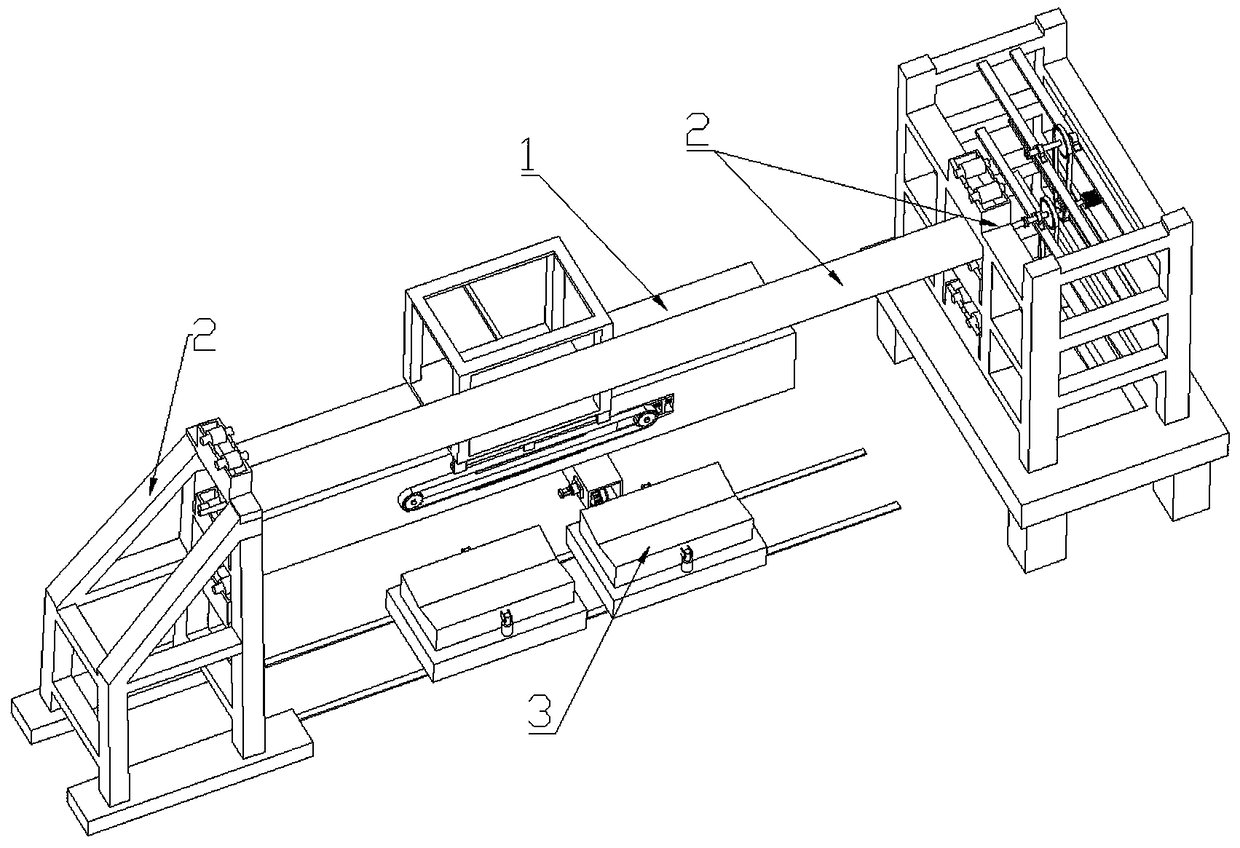

The invention discloses a coiling machine and method for a glass reinforced plastic pipe. The machine comprises a yarn feeding device, a coiling device and a die releasing device, wherein the yarn feeding device comprises a coiling platform, and a coiling trolley which is arranged on the coiling platform and is used for driving a yarn bundle to reciprocate in a direction parallel to the axial direction, wherein a transverse moving mechanism is arranged on the coiling platform and is used for controlling the coiling platform and the coiling trolley to axially parallelly move and position in thedirection vertical to a core die. The method comprises the steps of A, adjusting the distance from the coiling platform to the core die; B, coiling; and C, releasing a die. According to the machine and the method, the distance from the coiling platform to the core dies with different diameters can be adjusted, and moreover, the core die can be separated from a glass reinforced plastic product. The machine and the method are applicable to the production of the glass reinforced plastic products as well as coiling of the glass reinforced plastic pipe and a glass reinforced plastic tank.

Owner:JIZHOU YAORONG GLASS FIBER REINFORCED PLASTIC EQUIP +1

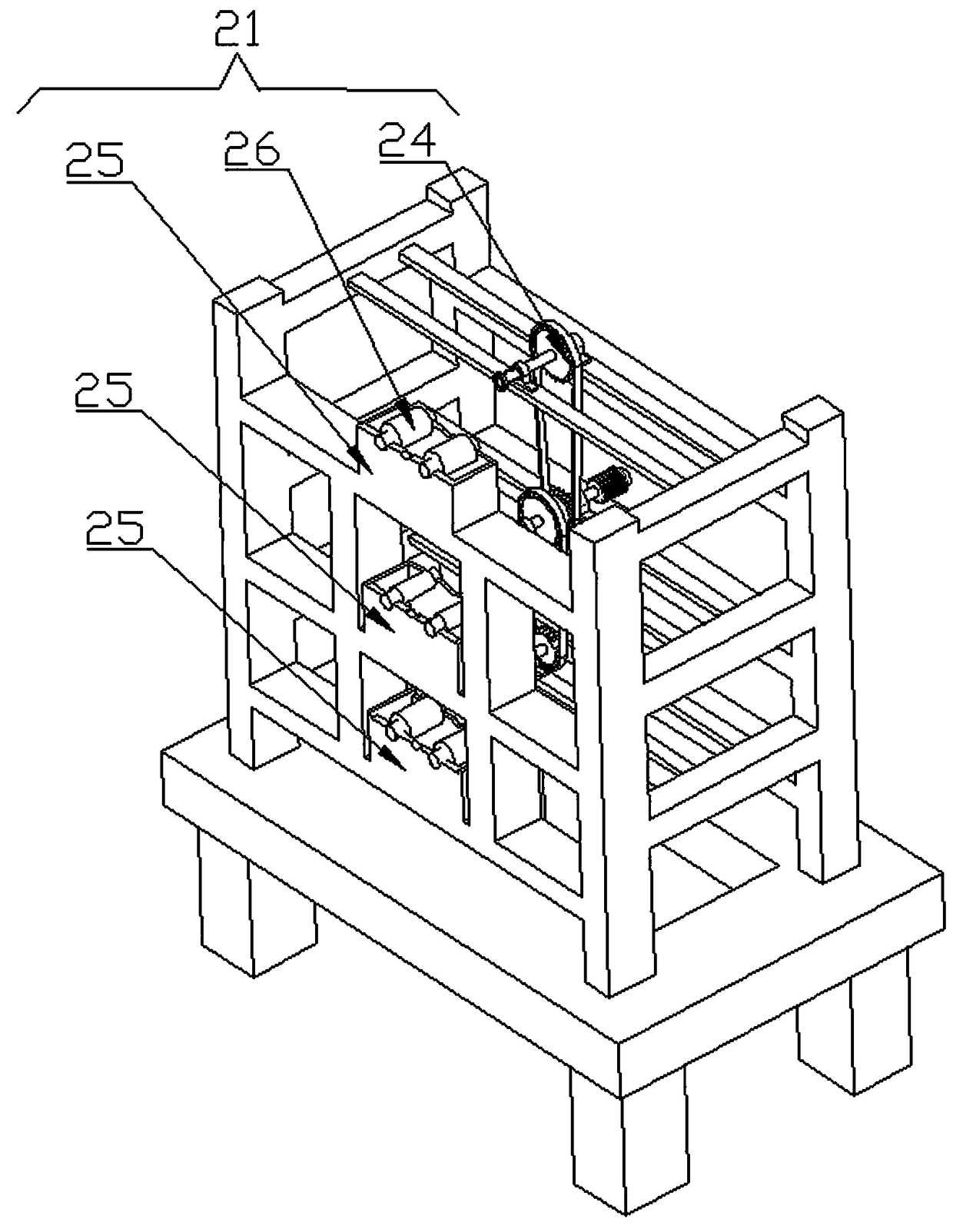

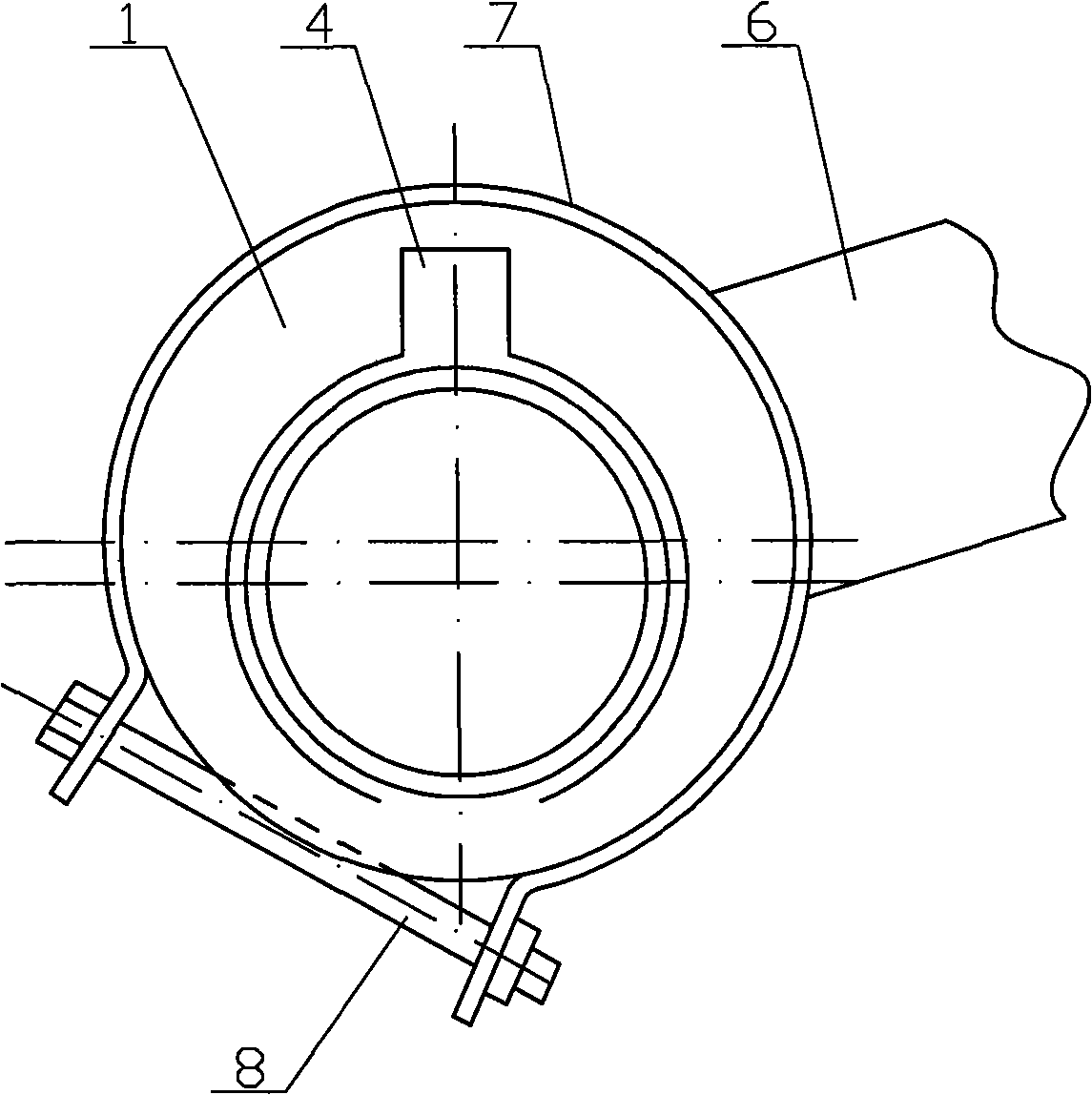

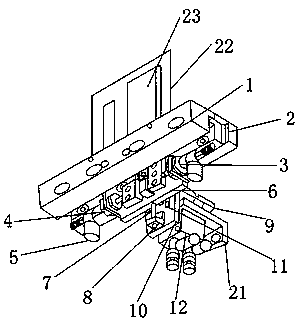

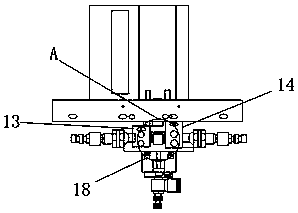

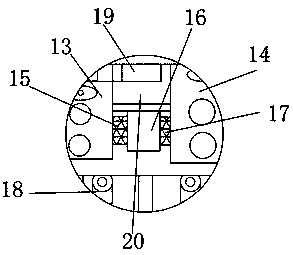

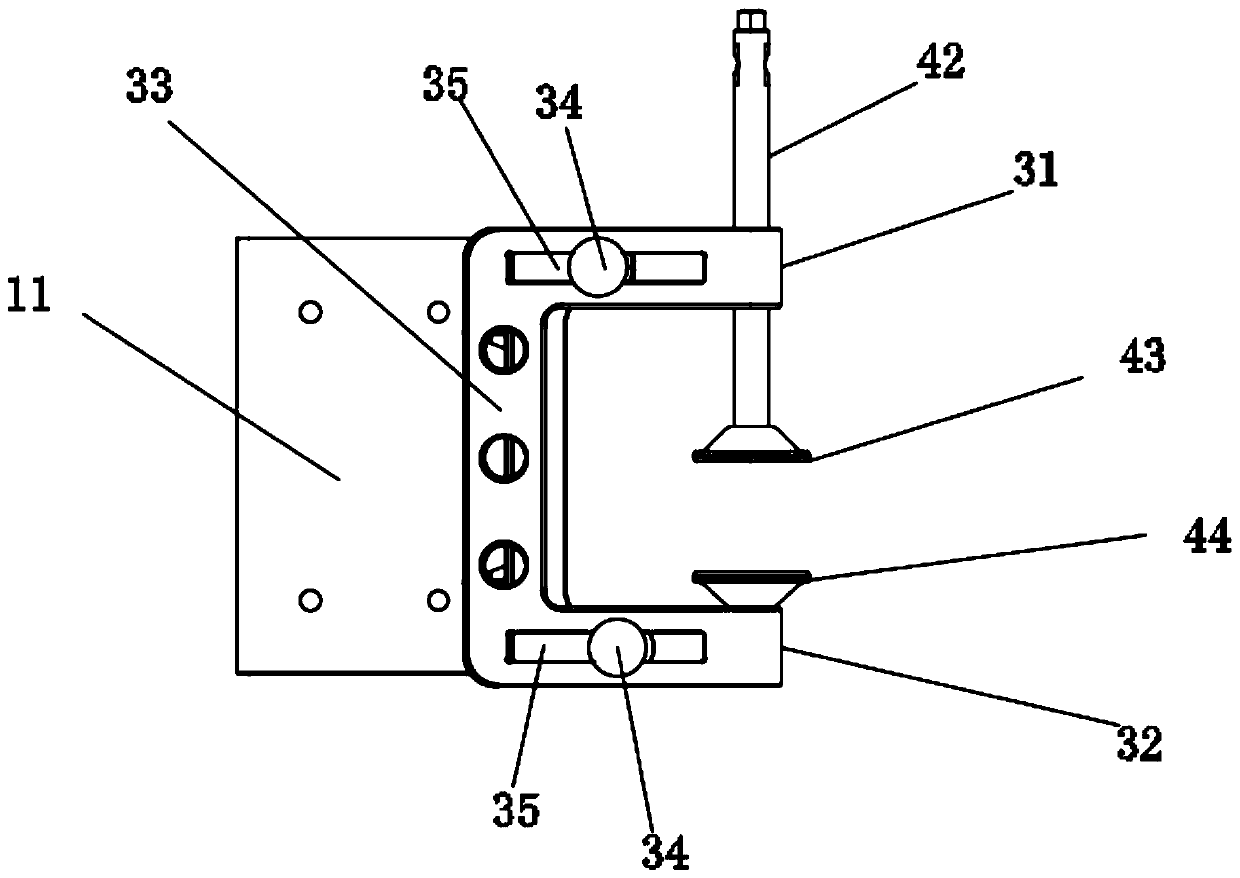

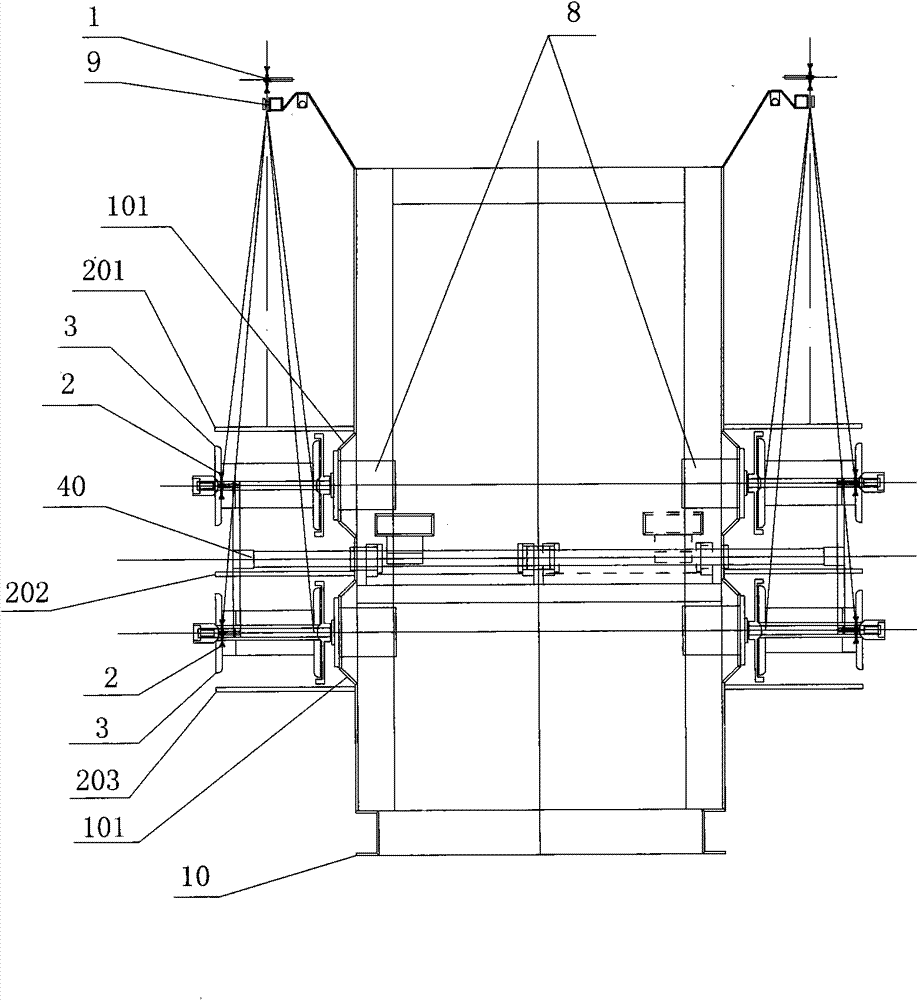

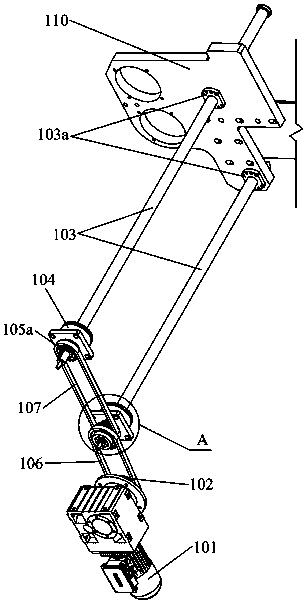

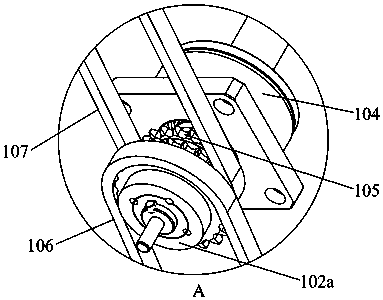

Automatic tube sheet welder positioning device

ActiveCN106825878AGuaranteed parallel movementFlexible moving processWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

The invention belongs to the field of spiral coil heat exchangers, and relates to the field of rotary argon protection automatic welding of heat exchange tube orifices and tube sheets, in particular to an automatic tube sheet welder positioning device which comprises horizontal, vertical and front-back linear movable guide rails. According to the automatic tube sheet welder positioning device, conical positioning mandrel and the rotating center of an adjustable-speed motor are coaxial, radial and axial positioning are performed, the conical positioning mandrel and a workpiece heat exchange pipe of a welding head are firstly positioned, retraction of the conical positioning mandrel is realized, a welding seam position is reserved, and welding cannot be affected. The rotating center of the welding head cannot deviate from the center of the heat exchange pipe after the positioning mandrel retracts, welding cannot be affected, and movable locking mechanisms are locked anywhere.

Owner:KAIFENG AIR SEPARATION GROUP

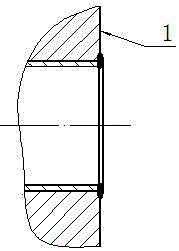

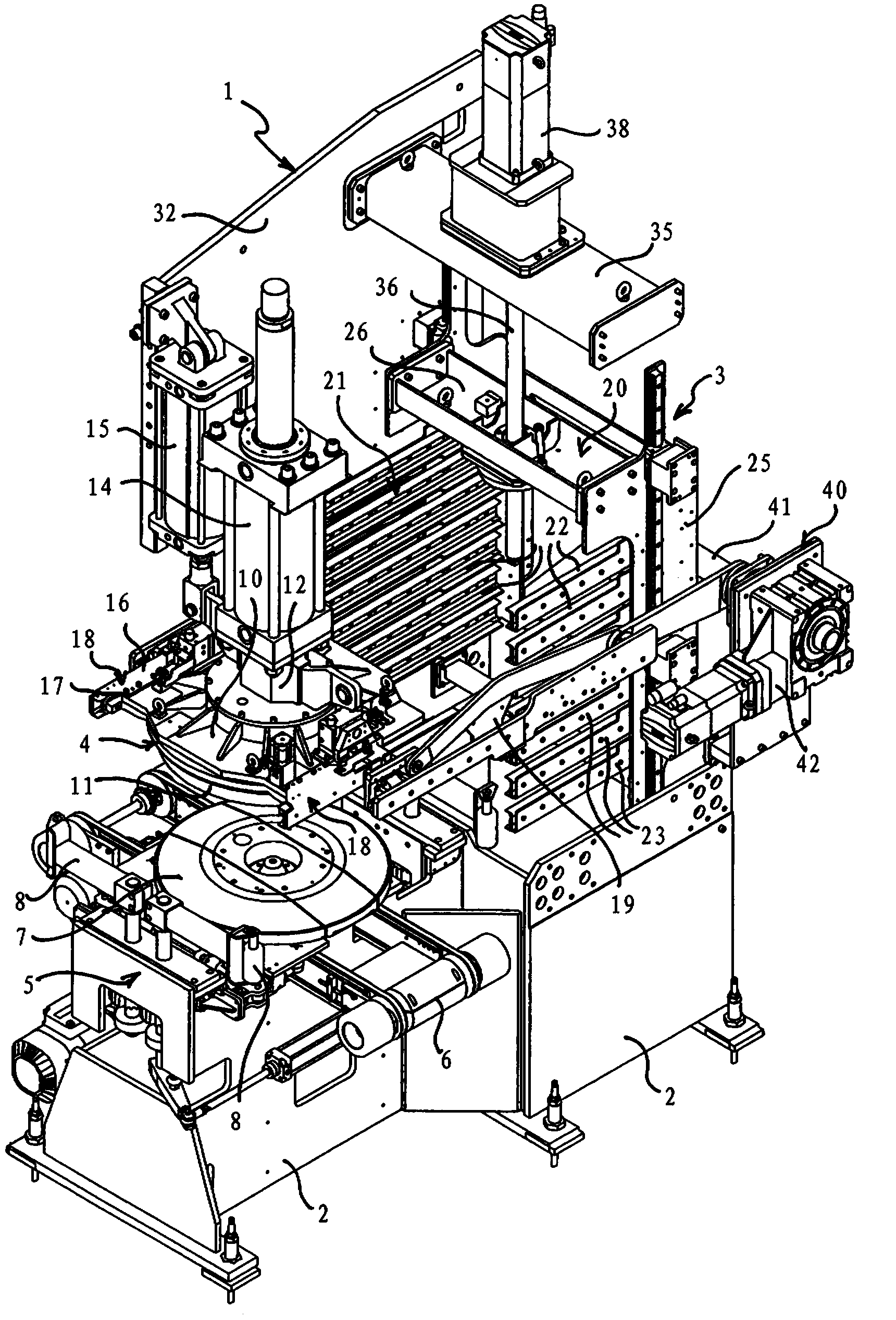

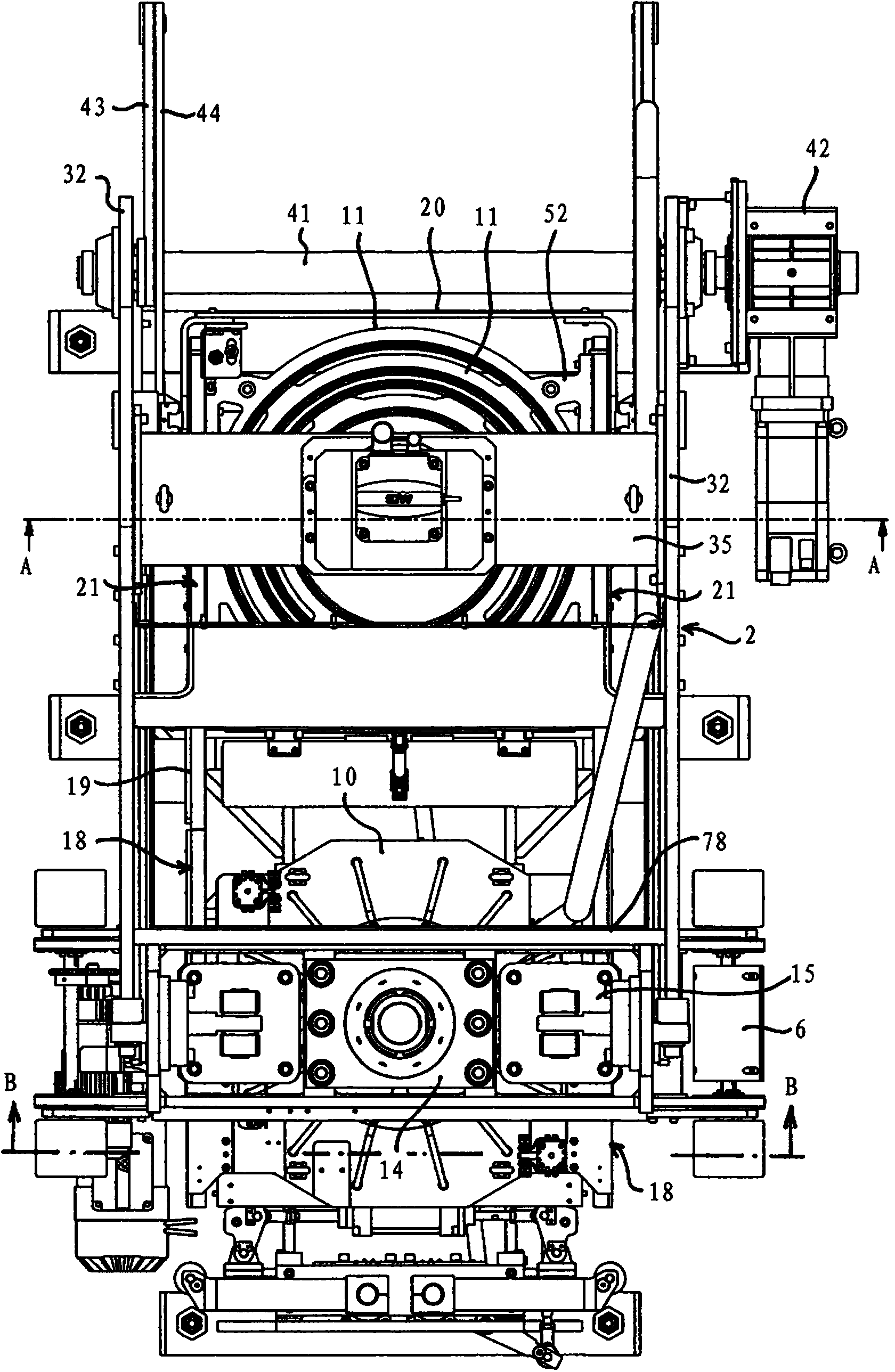

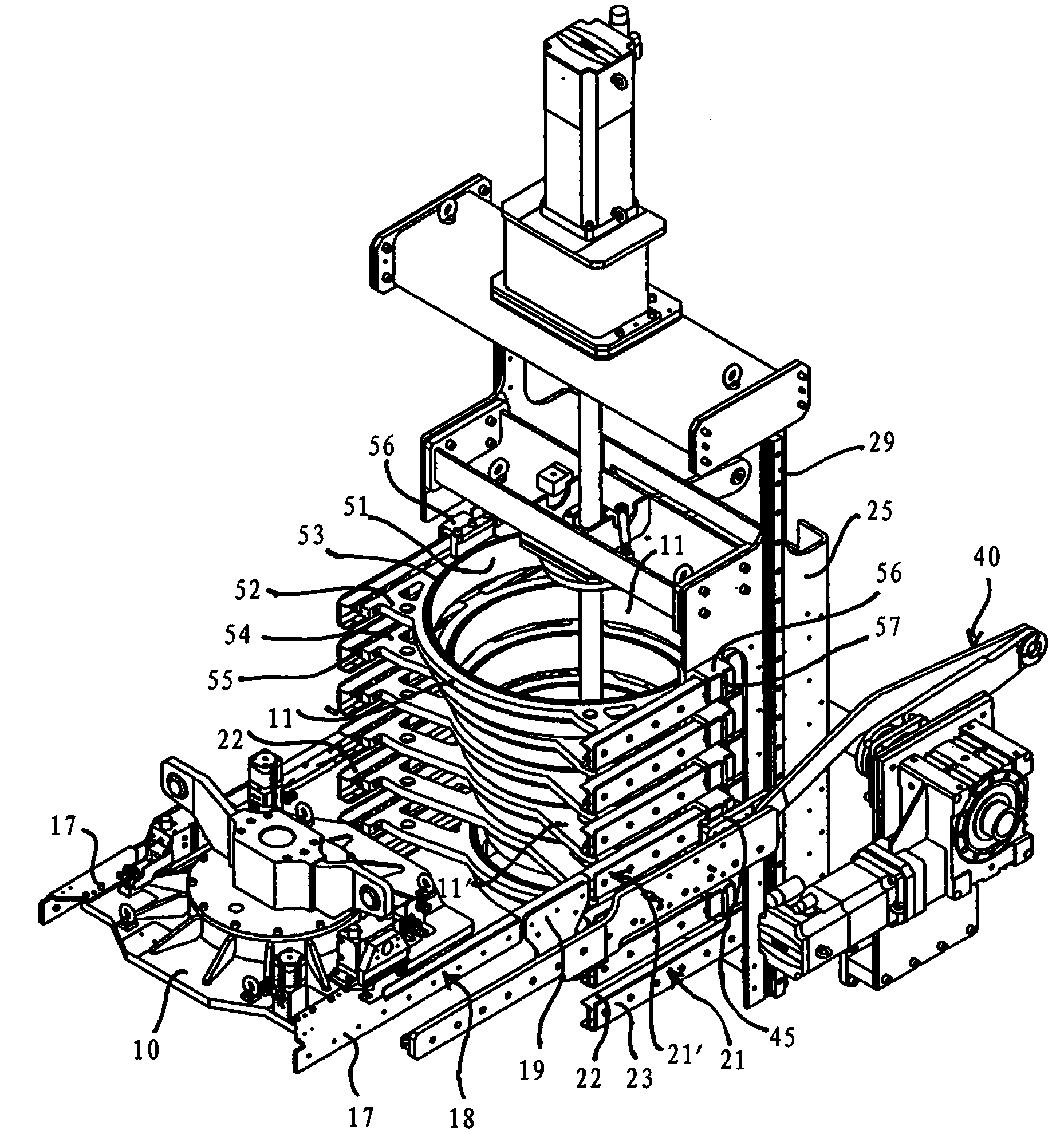

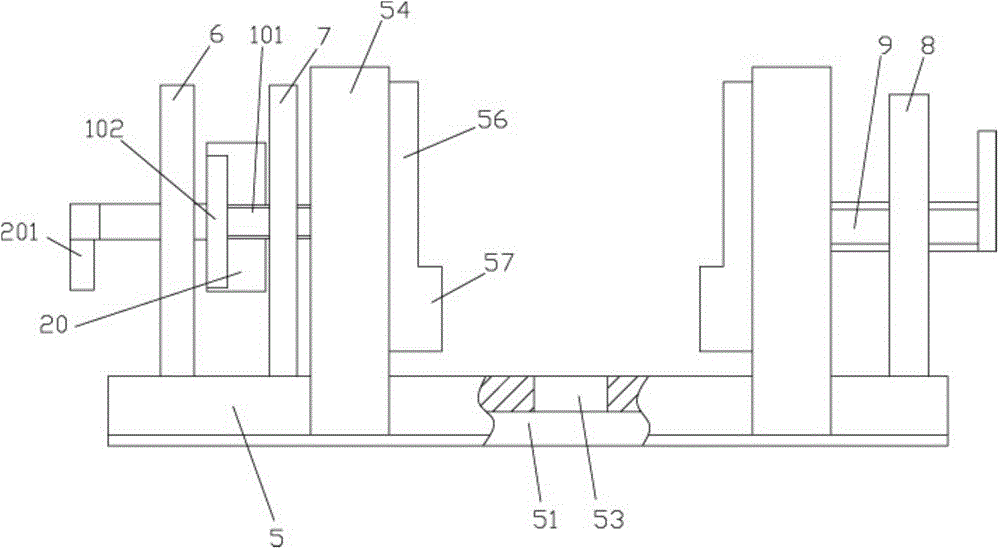

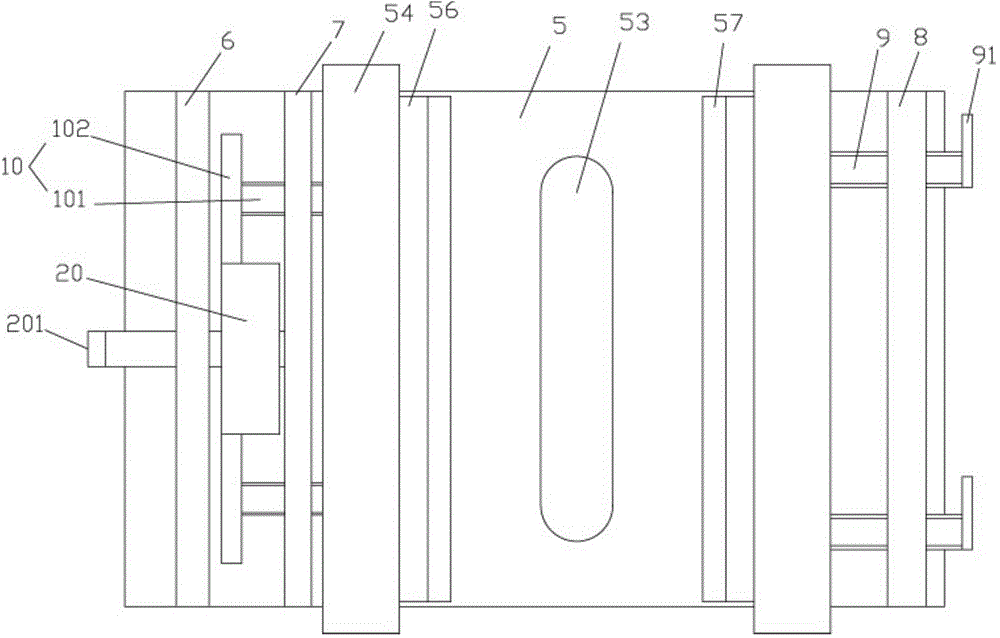

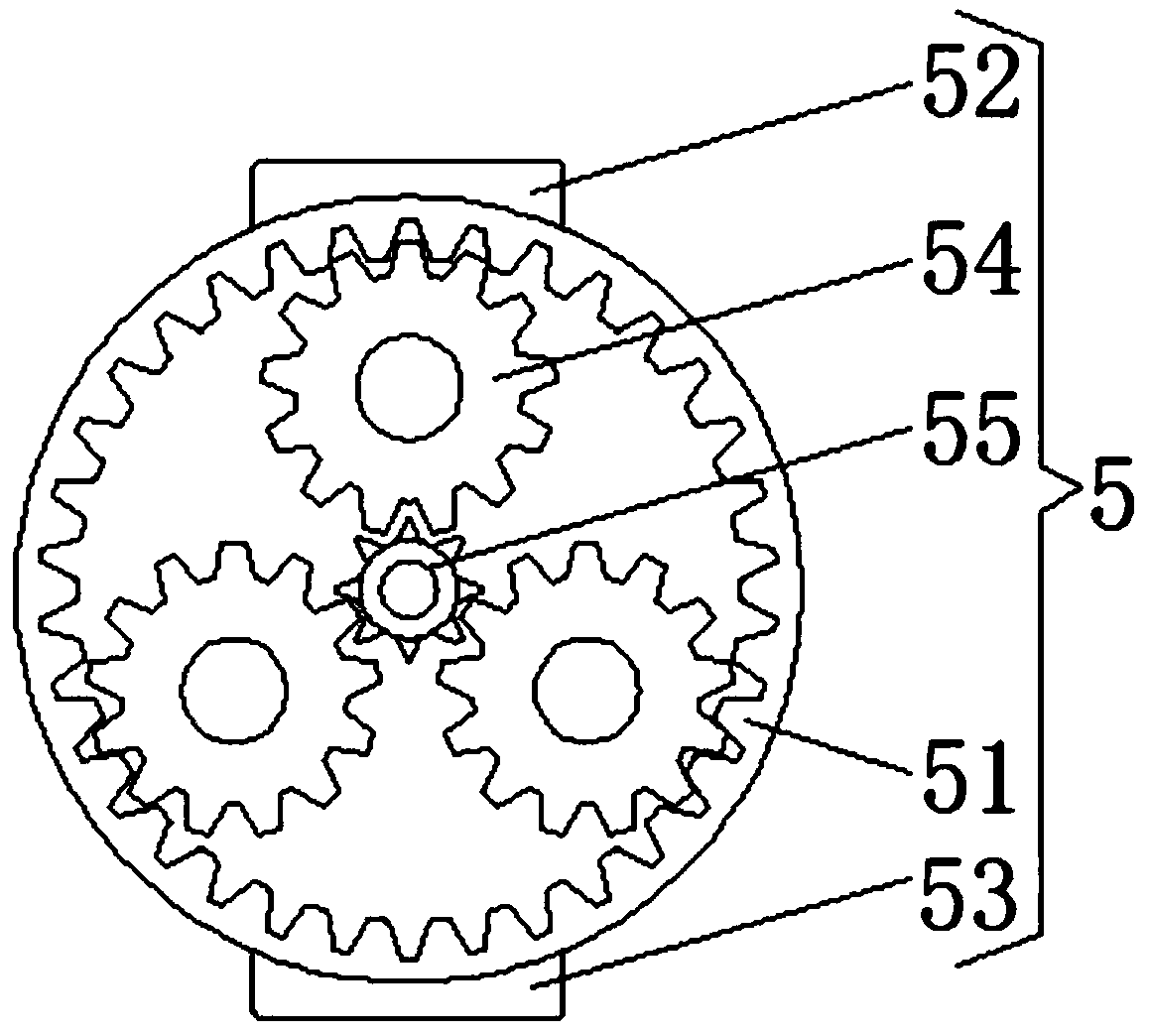

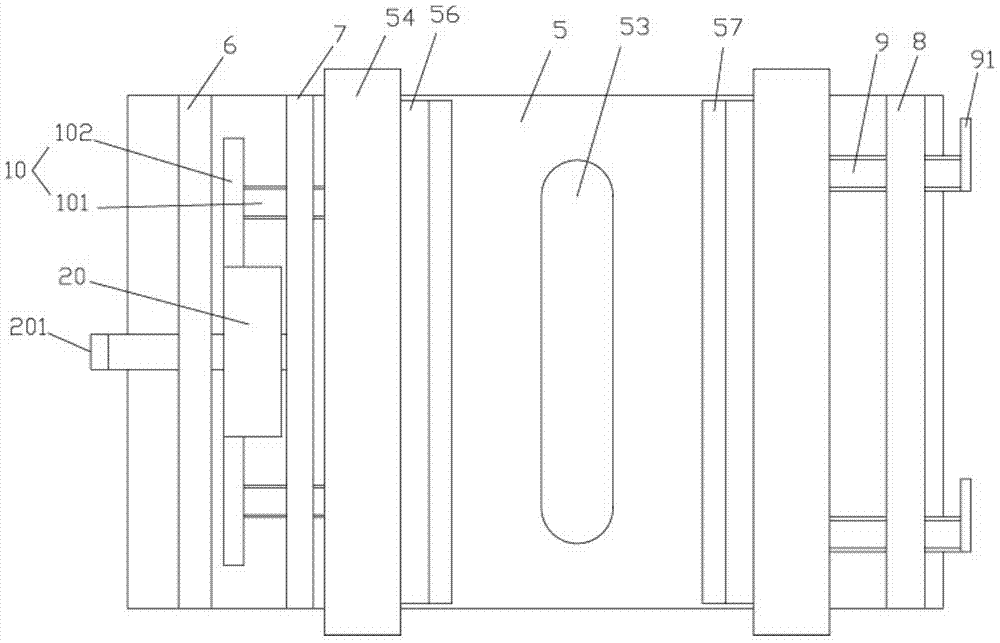

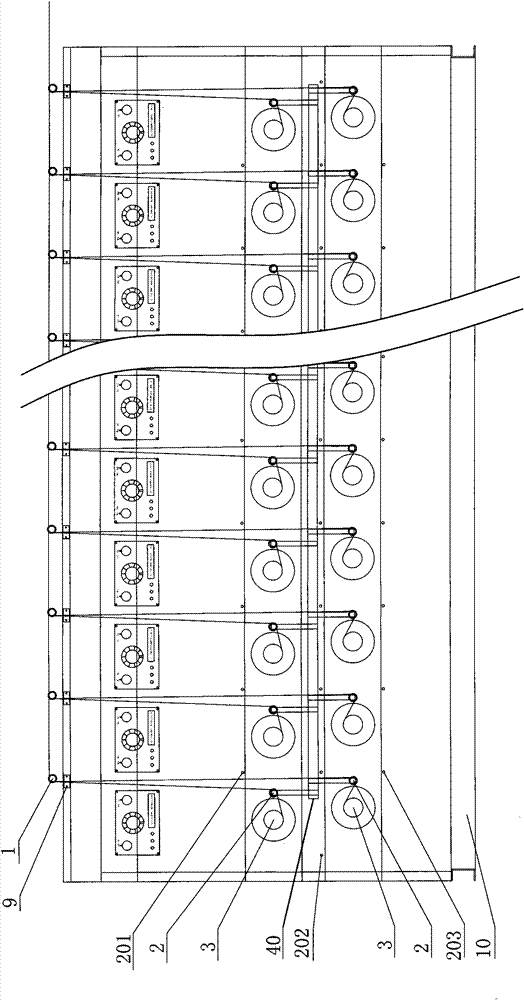

Tyre inflation device

ActiveCN104108381AReduced Tolerance RequirementsAutomatic decouplingVehicle servicing/repairingTyre repairingMechanical engineeringParallel plane

In a tire inflating device having a machine frame (2), a tire filling bell (4) arranged on the machine frame (2) and a supporting and sealing device (5) for sealing a filling chamber. The tire filling bell (4) is comprised of a filling plate (10) and a separate filling ring (11). A magazine (3) has a magazine rack (20) and magazine guides (21) lying in a plurality of parallel planes, each of said guides being able to hold a filling ring (11, 11′) mounted so that it can move. The magazine rack (20) and the filling plate (10) can be moved with respect to each other into a plurality of transfer positions in the direction of the axis of rotation. The magazine guide (21) in each case is connected to a filling plate guide (18) arranged on the filling plate (10) in said transfer positions. A filling ring (11) which is located in the magazine guide (21) arranged in the transfer position can be conveyed by a conveying device (40) into a filling plate guide and a centered position on the filling plate (10).

Owner:SCHENCK ROTEC GMBH

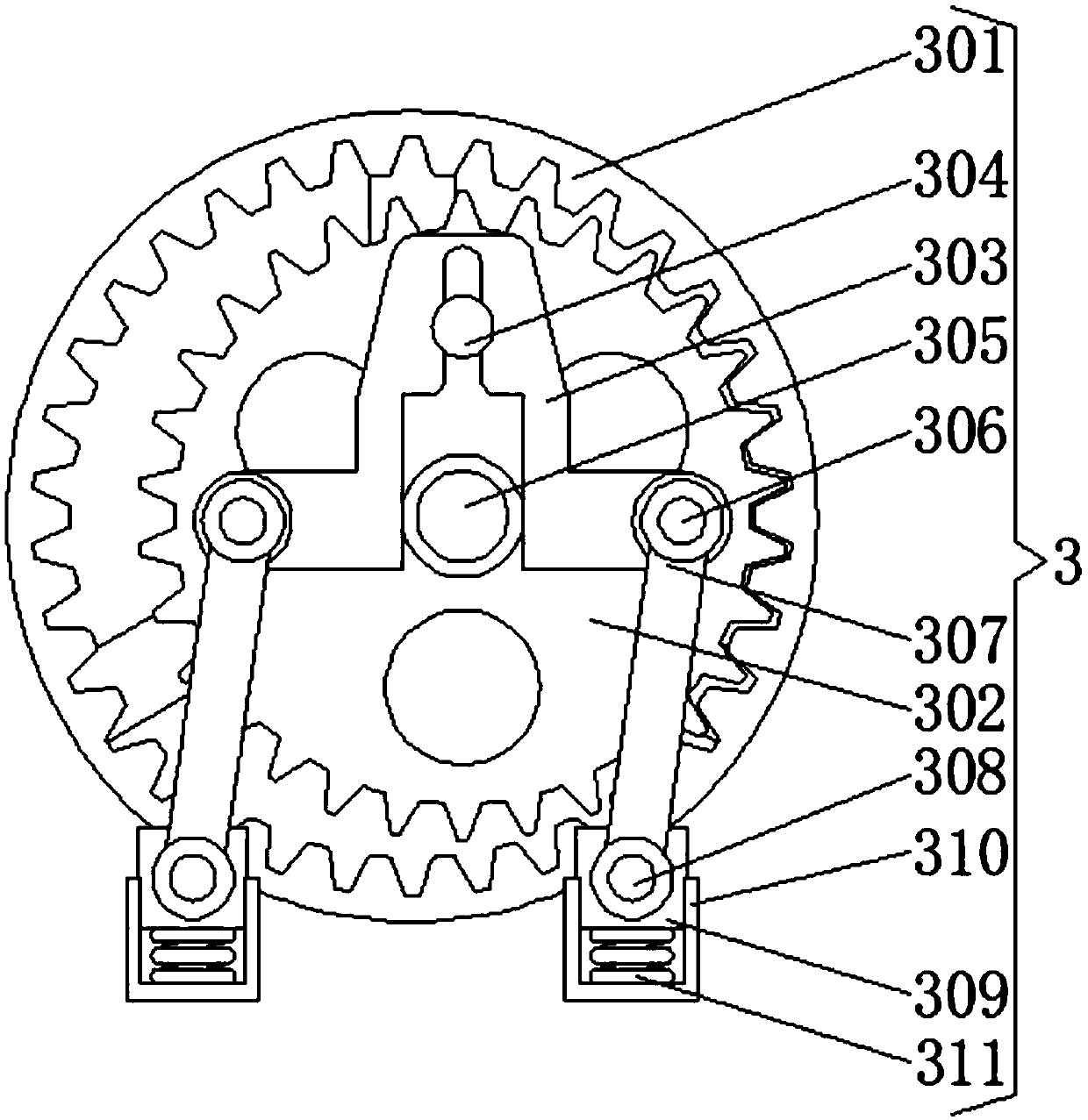

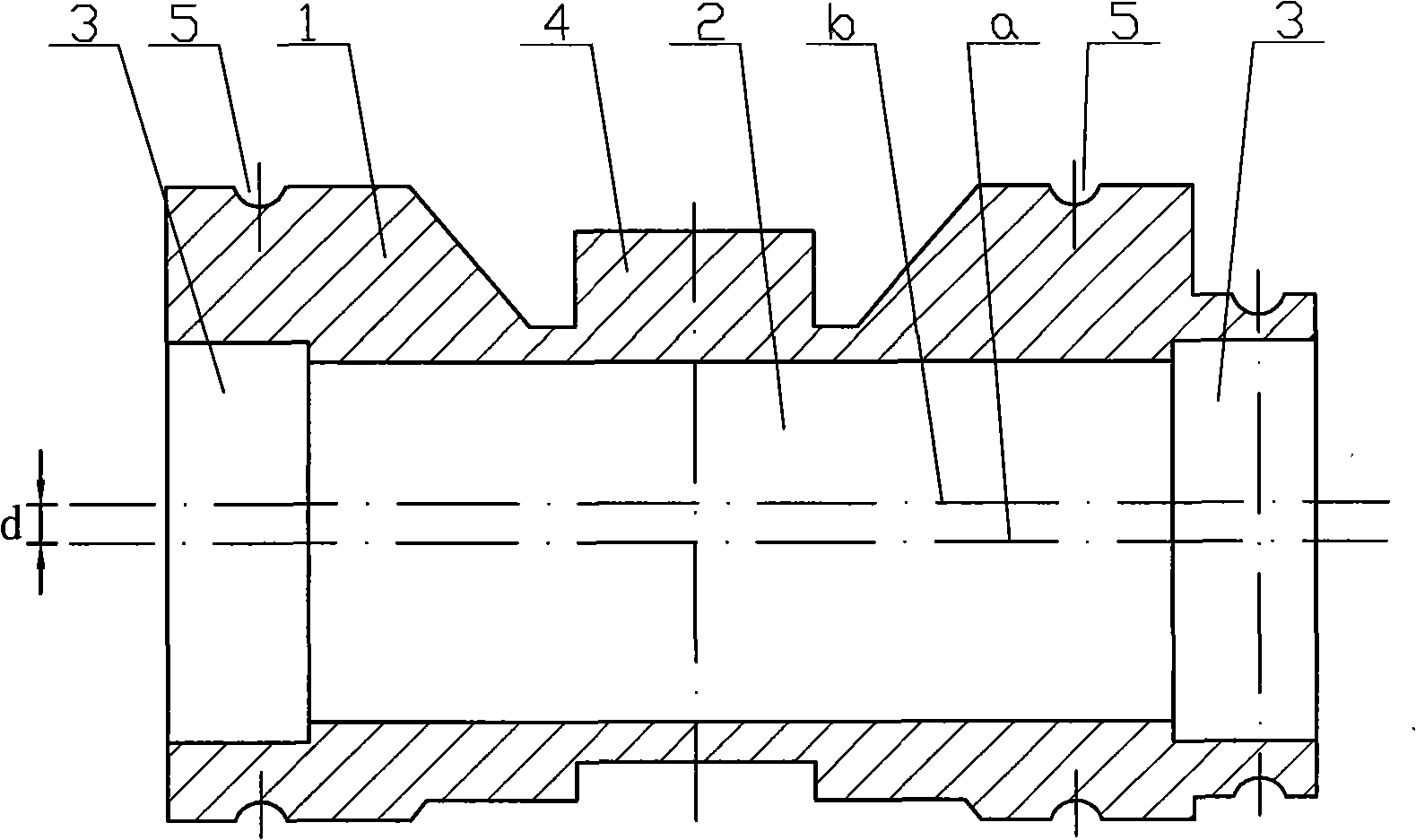

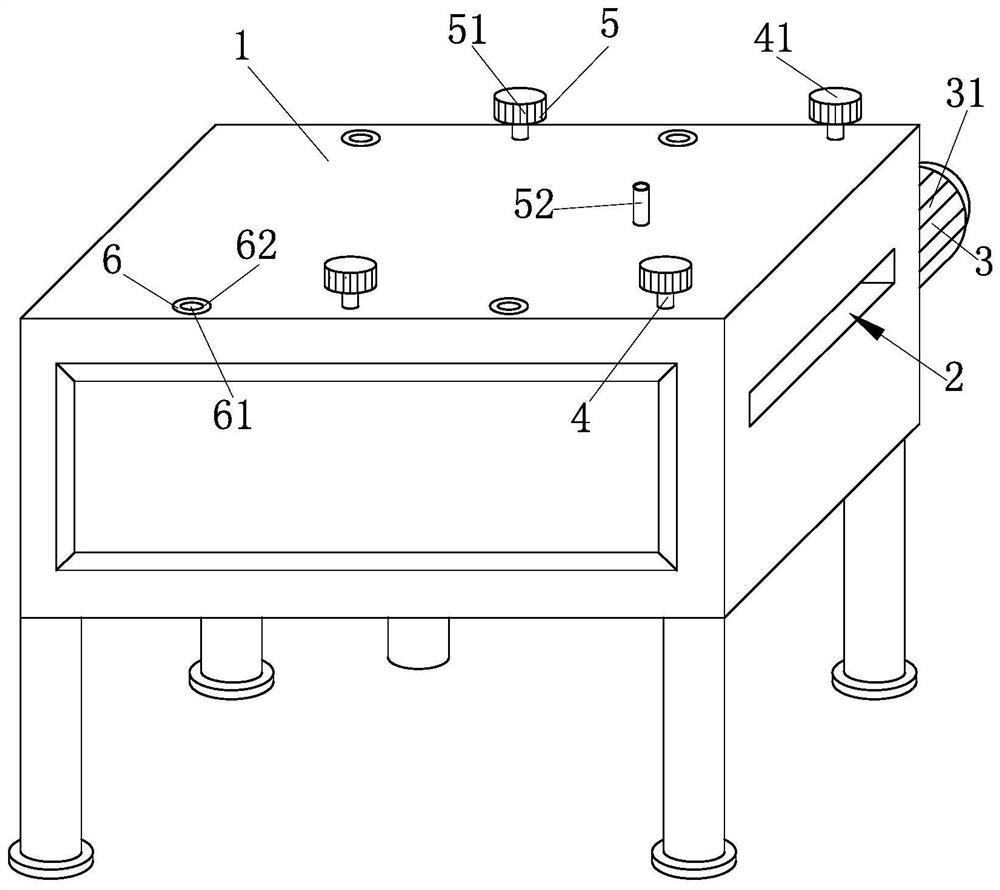

Workpiece clamping device of track of machine tool

ActiveCN104440546AGuaranteed parallel movementGuaranteed service lifeGrinding work supportsEngineeringMachine tool

The invention discloses a workpiece clamping device of a track of a machine tool. The workpiece clamping device of the track of the machine tool comprises a base plate and a longitudinal adjusting base plate, wherein a longitudinal moving groove is formed in the bottom of the base plate; an adjusting screw hole is formed in a side wall of the base plate; at least two transverse adjusting tracks are fixed on the top of the base plate; adjusting grooves which are matched with the adjusting tracks are formed in the bottom of an upper clamping adjusting block; the adjusting tracks are inserted in the adjusting grooves; supporting plates are fixed at the front end and the rear end of the base plate; two ends of an adjusting lead screw are hinged to the two supporting plates; the middle of the adjusting lead screw is in screwed connection to screwed connection through holes formed in the left side and the right side of the upper clamping adjusting block; a bottom chute is formed in the bottom of the longitudinal adjusting base plate; and a dovetail-shaped sliding track which is arranged on the upper portion of the upper clamping adjusting block is inserted in the bottom chute. Two adjusting gear screws move synchronously by rotating a middle adjusting gear, an adjusting clamping block on the left side can move in parallel, and workpieces can be quickly adjusted in the transverse direction and the longitudinal direction.

Owner:金丽丹

Cleaning assembly of tinning device

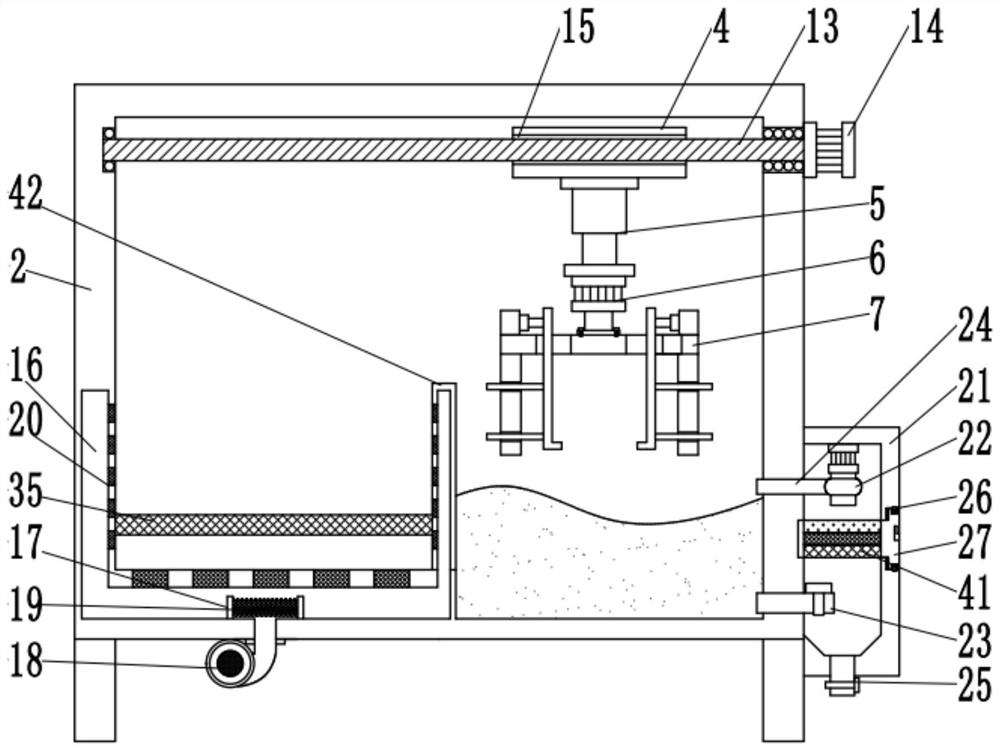

InactiveCN112246771AGuaranteed parallel movementImprove stabilityDrying gas arrangementsCleaning using liquidsHydraulic cylinderTinning

The invention relates to the technical field of tinning, in particular to a cleaning assembly of a tinning device. The cleaning assembly comprises a base and a movable block. A cleaning box and a tinning box are mounted on the outer wall of the top of the base through bolts. A lifting hydraulic cylinder is mounted on the outer wall of the bottom of the movable block through a bolt. A rotary motoris mounted at the output end of the bottom of the lifting hydraulic cylinder through a bolt. A mounting seat is mounted at the output end of the bottom of the rotary motor through a bolt. Clamping hydraulic cylinders are mounted on the two sides of the outer wall of the top of the mounting seat through bolts. Through grooves are formed in the two sides of the outer wall of the top of the mountingseat. The cleaning assembly has the advantages that the clamping hydraulic cylinders can enable clamping seats to clamp metal plates of different specifications, and the application range is wider; meanwhile, guide rods can guarantee parallel movement of the clamping seats, and stability is improved; and hot air can be blown into the cleaning box, the cleaned metal plates can be dried, and the situation that the metal plates with water are directly tinned can be avoided.

Owner:江西勇骏实业有限公司

Pipeline inner wall shot blasting device

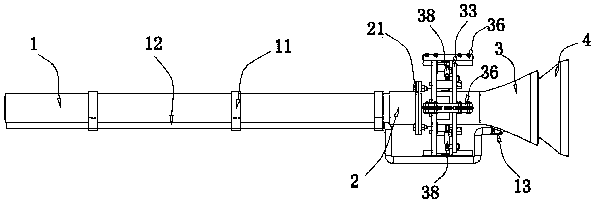

PendingCN108326755AGuaranteed parallel movementAbrasive feedersAbrasive blasting machinesPeeningSpray nozzle

The invention provides a pipeline inner wall shot blasting device which is used for conducting shot blasting treatment on the inner wall of a pipeline. The conveying pipeline is of a tubular structureand is fixedly connected with the small end of a trumpet-shaped separation pipeline. A high-pressure air pipe is arranged on the conveying pipeline. A spray nozzle extending into the separation pipeline is arranged at the tail end of the high-pressure air pipe. A base is fixed to the separation pipeline. A plurality of wheel carriers arranged uniformly in the circumferential direction are slidably mounted on the base. An adjusting mechanism for driving the wheel carriers to move in the radial direction is arranged on the base. A high-pressure gas outer tube is arranged in the separation pipeline. A shot blasting channel is formed between the high-pressure gas outer tube and the separation pipeline. A high-pressure gas inner tube is arranged in the high-pressure gas outer tube. A high-pressure gas channel is formed between the high-pressure gas inner tube and the high-pressure gas outer tube. The high-pressure gas outer tube is provided with gas holes communicating with the high-pressure gas channel. The pipeline inner wall shot blasting device can conduct shot blasting operation on the inner wall of the pipeline conveniently and can conduct shot blasting on the inner wall of the whole pipeline.

Owner:UNIV OF JINAN

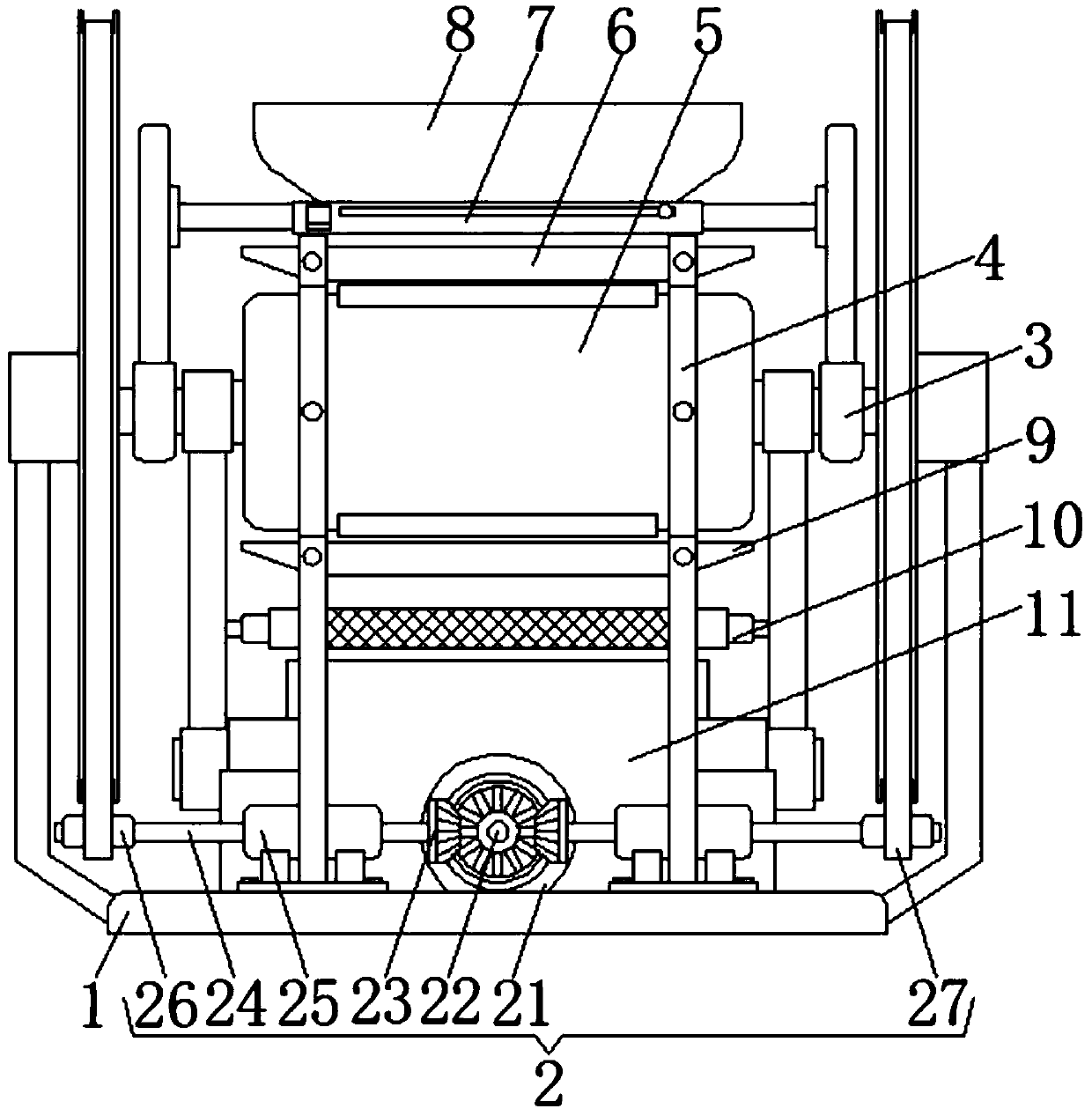

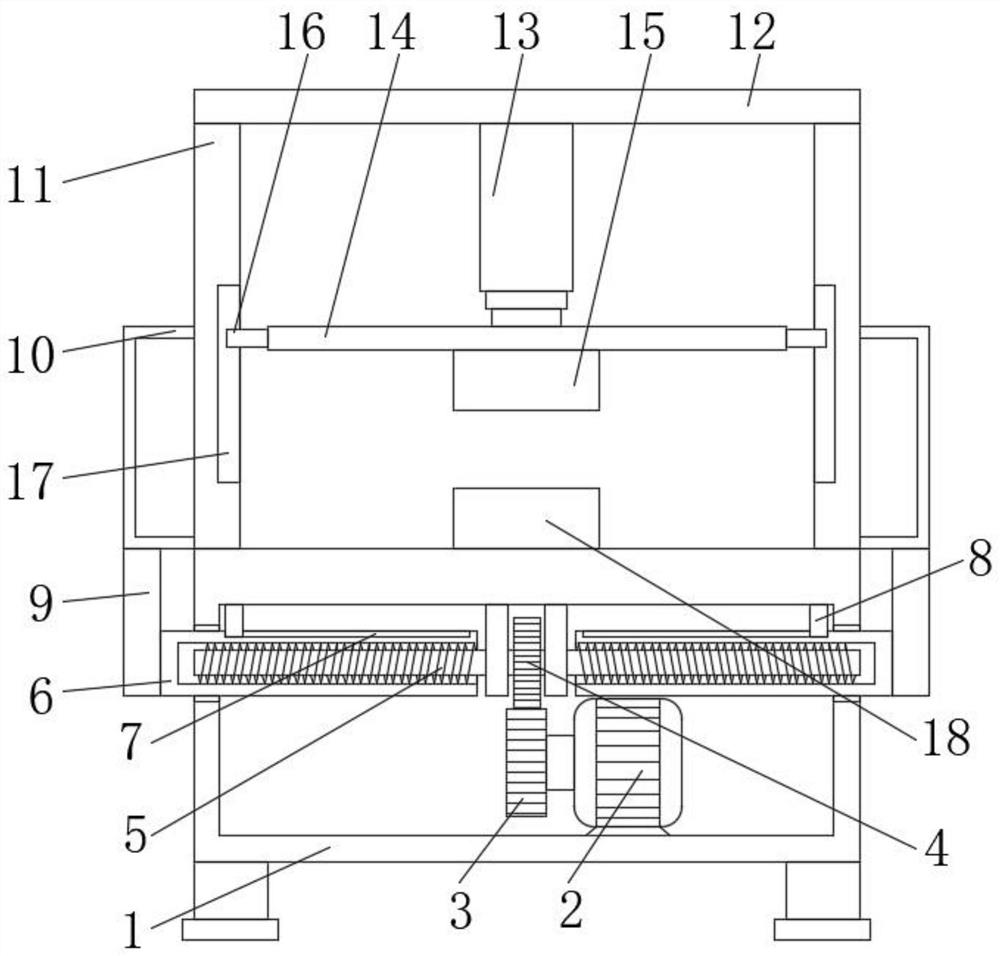

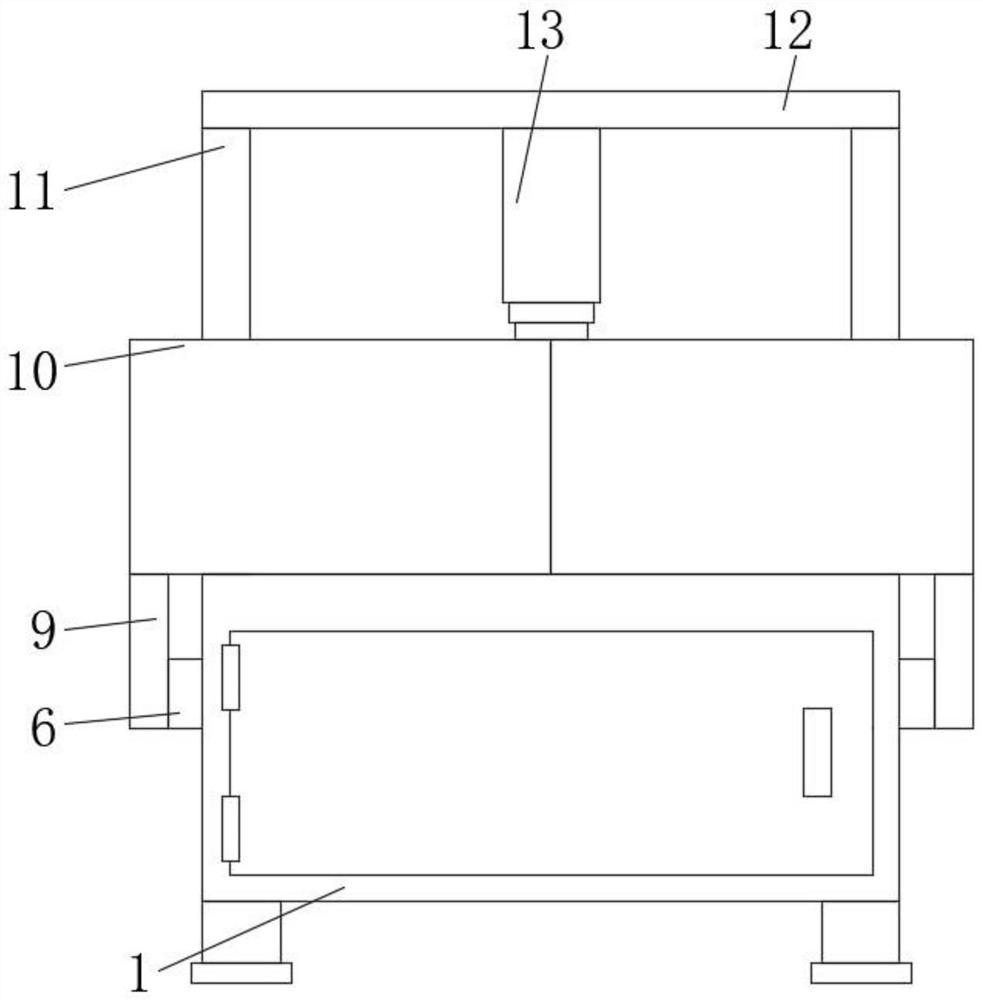

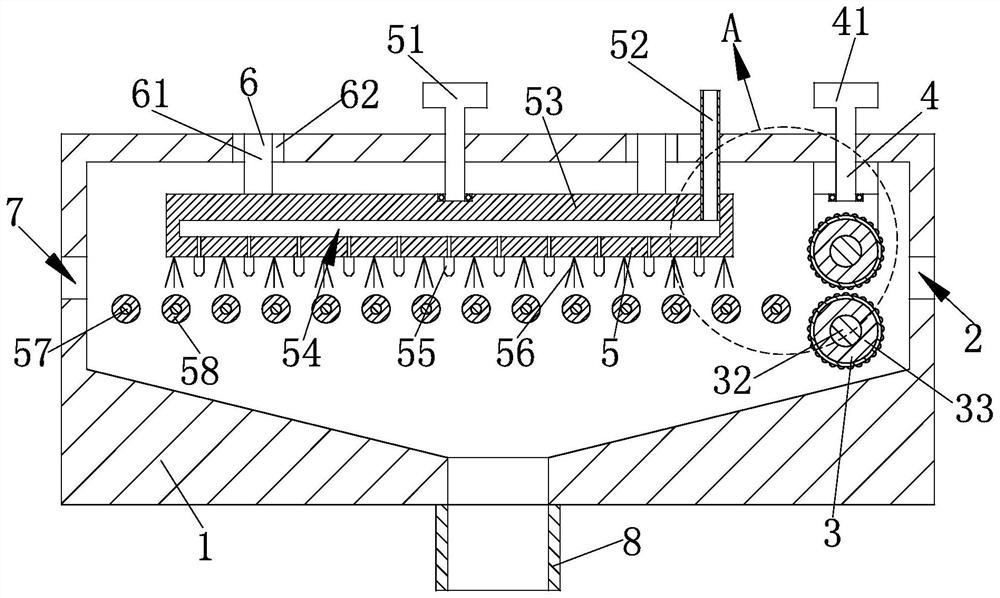

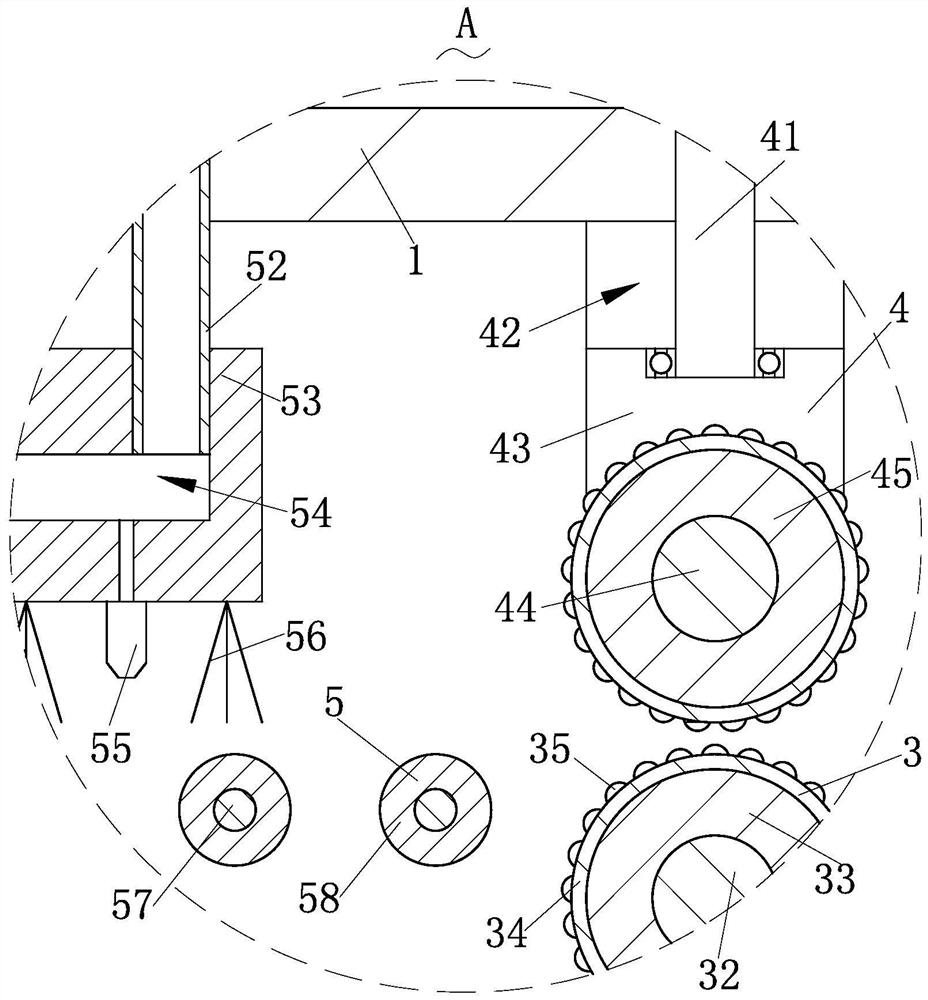

Organic fertilizer processing apparatus with linkage-power anti-blocking function and quantity controlled crushing function

InactiveCN108672023AAvoid clogging the screenEasy to removeSievingScreeningProcess engineeringOrganic fertilizer

The invention discloses an organic fertilizer processing apparatus with linkage-power anti-blocking function and quantity controlled crushing function, which relates to the technical field of fertilizer processing. The organic fertilizer processing apparatus with linkage-power anti-blocking function and quantity controlled crushing function comprises a base, wherein a transmission mechanism is fixedly mounted on a top of the base; joint swinging mechanisms are arranged on both sides of the top of the transmission mechanism; four fixed rods are symmetrically arranged between the two joint swinging mechanisms; and the four fixed rods are fixedly connected to the front and rear sides of the base respectively in groups of two. According to the organic fertilizer processing apparatus with linkage-power anti-blocking function and quantity controlled crushing function, by arranging the transmission mechanism, the manual anti-blocking mechanism and the screen plate can be driven to shake whilethe raw materials are crushed. Moreover, by arranging the manual anti-blocking mechanism, raw materials stacked on the screen net can be easily removed, and the problem that in the prior art, the discharge of a large number of fertilizer crushing apparatuses is blocked, is effectively solved.

Owner:邱学岭

Workpiece clamping device provided with rails with longitudinal moving functions for machine tool

ActiveCN104476391AImprove efficiencyGood parallelismHoning machinesGrinding work supportsKidneyEngineering

The invention discloses a workpiece clamping device provided with rails with longitudinal moving functions for a machine tool. The workpiece clamping device comprises a longitudinal adjusting base plate. A bottom slide groove is formed in the bottom of the longitudinal adjusting base plate, longitudinal fixing screw holes are formed in a side wall of the bottom slide groove, a kidney-shaped straight slot is formed in the middle of the longitudinal adjusting base plate, two adjusting clamping blocks are arranged on the longitudinal adjusting base plate and are arranged on two sides of the kidney-shaped straight slot, main grooves are formed in the bottoms of the adjusting clamping blocks, and the upper portion of the longitudinal adjusting base plate is inserted in the main grooves. The workpiece clamping device has the advantages that a middle adjusting gear can rotate, so that two adjusting gear screws can synchronously move, the adjusting clamping block on the left side of the kidney-shaped straight slot can assuredly parallelly move, high adjusting efficiency can be guaranteed, the workpiece clamping device is good in parallelism, the probability that the adjusting clamping blocks are jammed on the longitudinal adjusting base plate can be reduced, and the service life of equipment can be guaranteed.

Owner:金丽丹

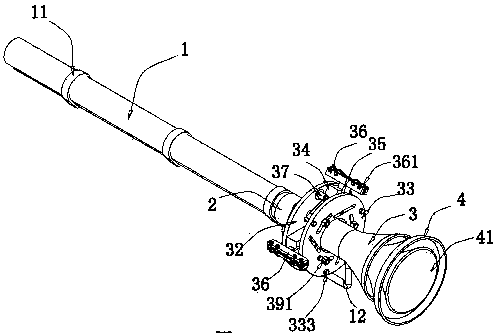

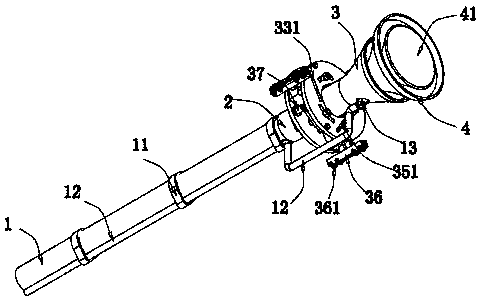

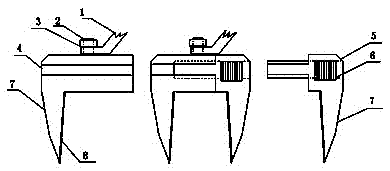

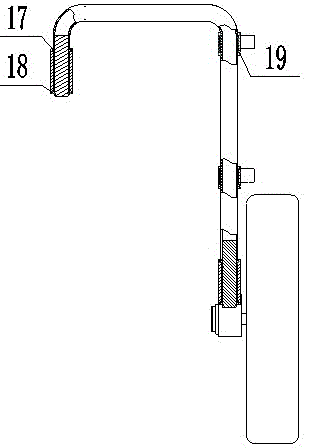

Prosthodontic tooth preparation axial surface convergence angle checker

InactiveCN106996734AGuarantee your own accuracyIncrease contrastAngles/taper measurementsEngineeringOral cavity

The invention discloses a prosthodontic tooth preparation axial surface convergence angle checker, which comprises a handle, a sliding rail and a sliding block, wherein the tail end of the handle is detachably connected with the sliding rail; the sliding block and the sliding rail are connected through a dovetail structure; the lower end of the sliding rail and the lower end of the sliding block are provided with working beaks; the opposite sides of the two working beaks are working surfaces; the included angle between the two working surfaces is 7 DEG; and the edge of each working surface is provided with a detection line. The checker has the advantages that the structure is simple; the use is convenient; the manufacturing cost is low; and the problem of inaccurate tooth preparation axial surface convergence angle judgment by naked eyes of a doctor can be well solved.

Owner:SHIYAN TAIHE HOSPITAL

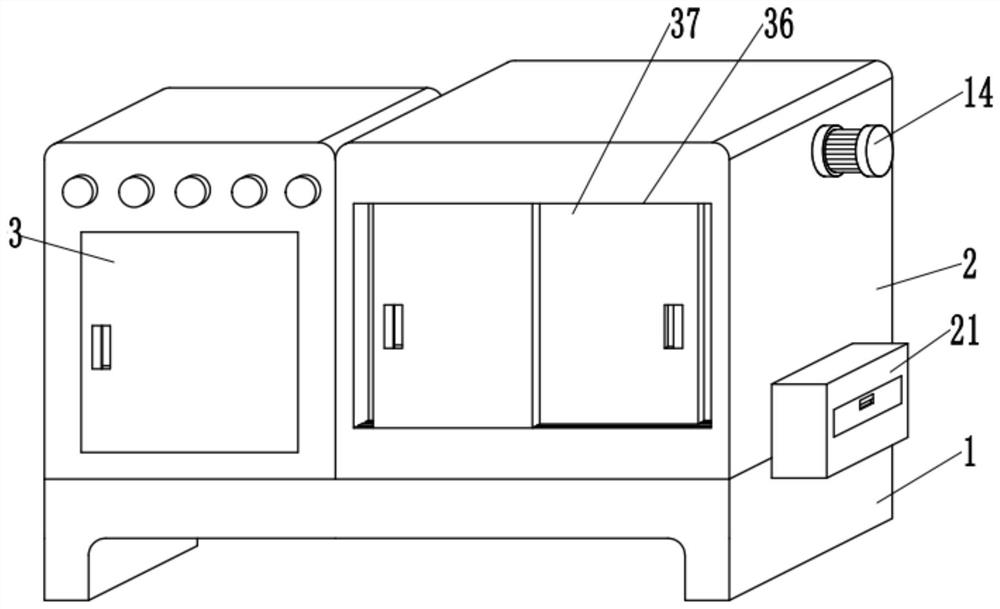

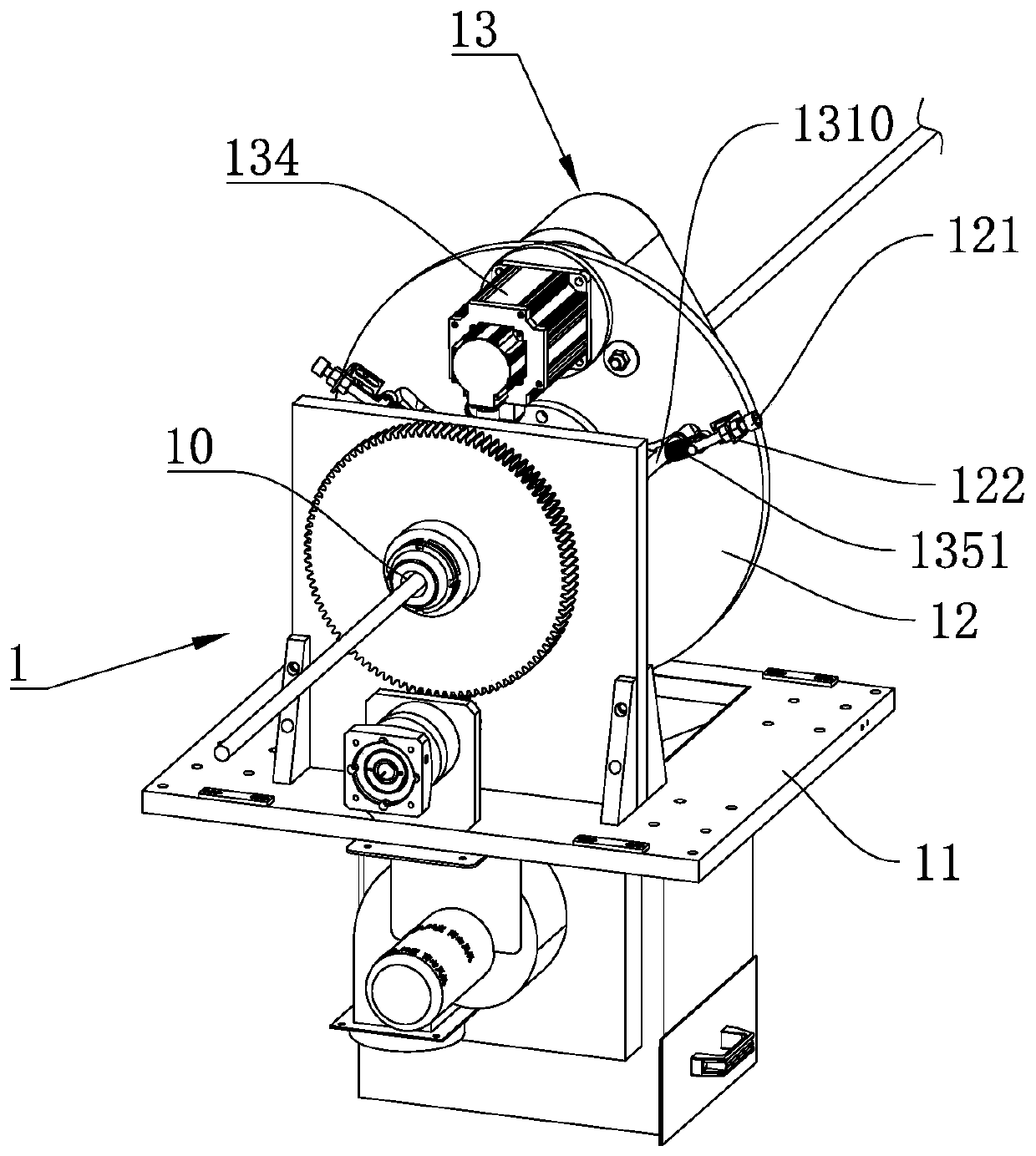

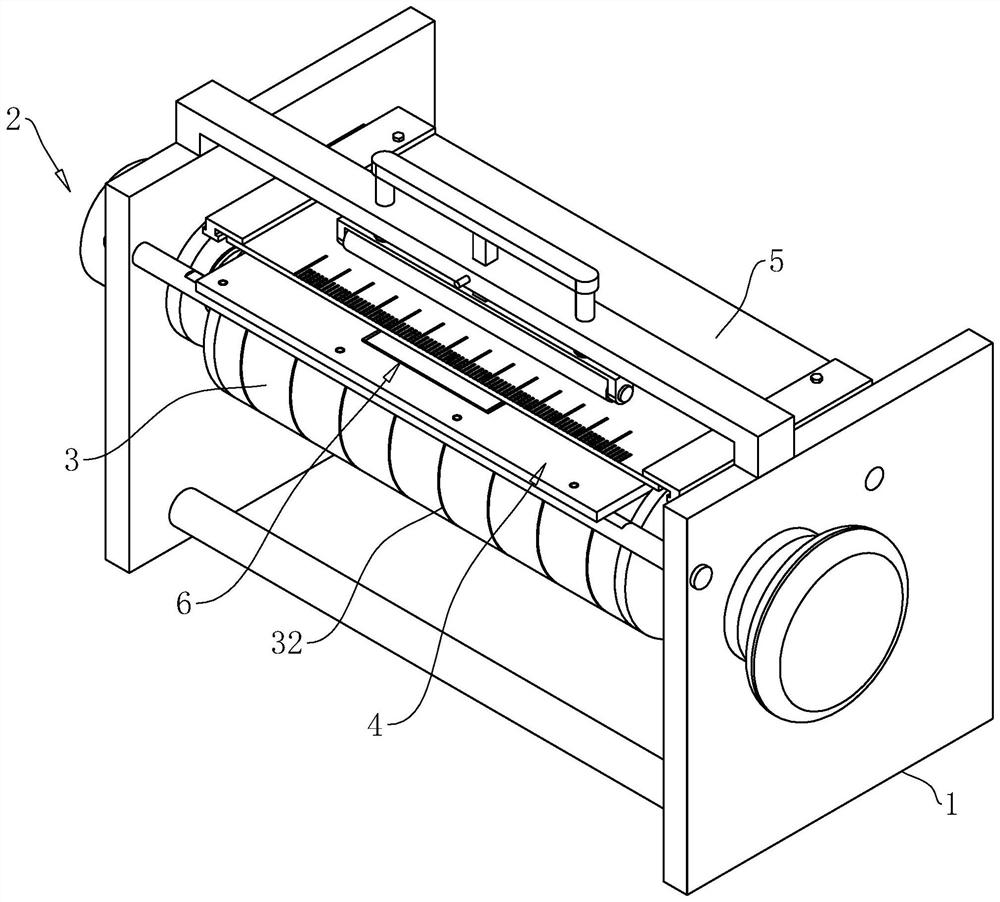

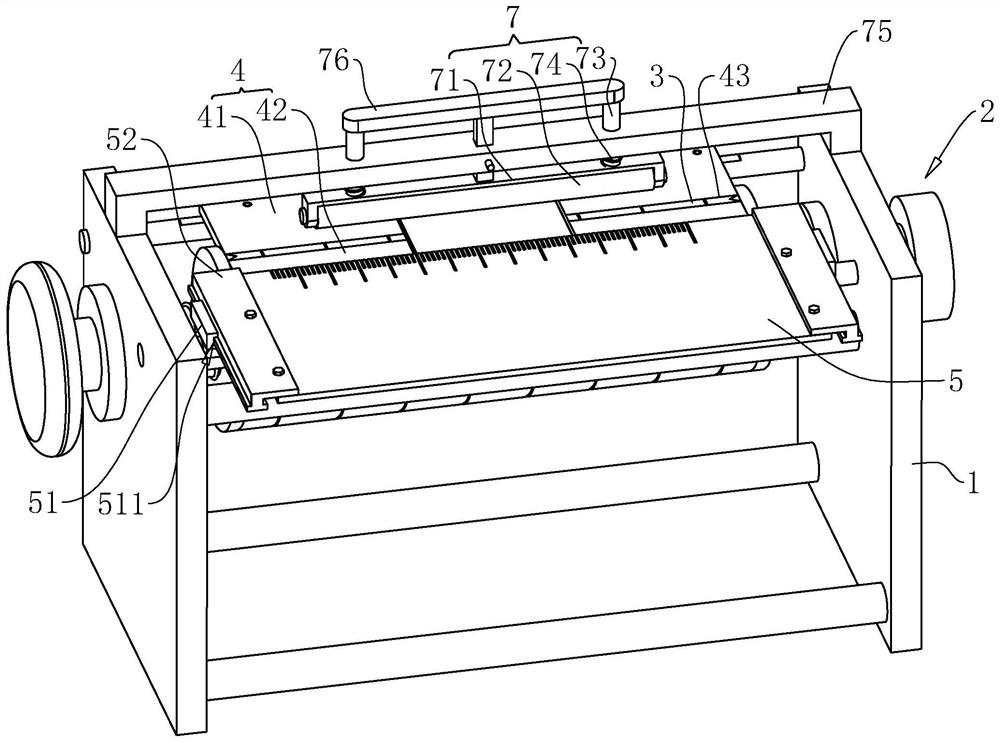

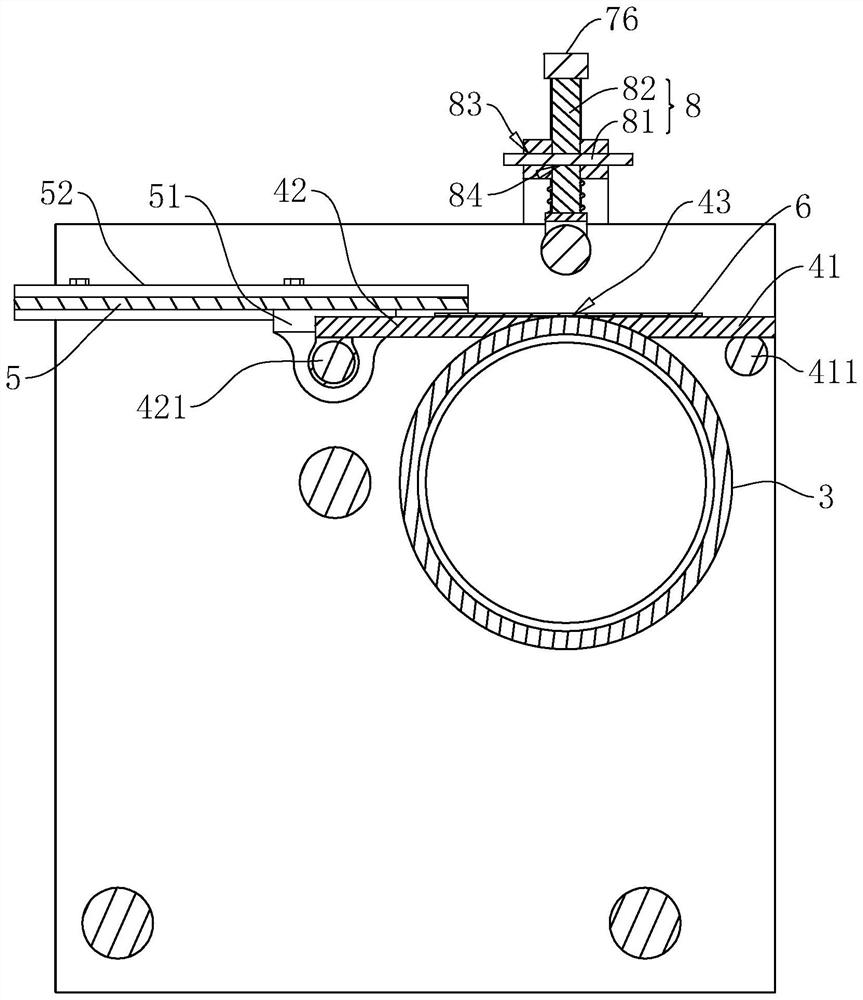

Automatic sharpening machine

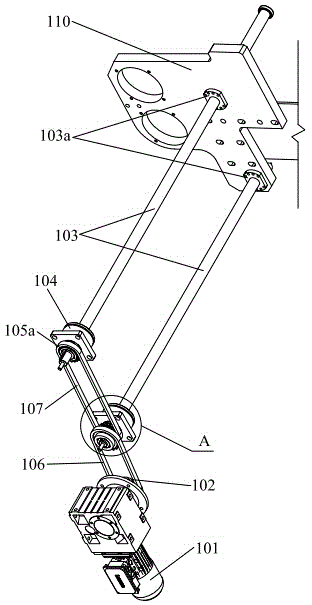

PendingCN111360656AImprove processing efficiencyImprove grinding effectGrinding drivesBelt grinding machinesLinear motionEngineering

The invention belongs to the technical field of machinery, and relates to an automatic sharpening machine. The automatic sharpening machine comprises a sharpening mechanism and a rack table, wherein the sharpening mechanism can do reciprocating linear motion along the rack table, a through steel wire channel is arranged in the sharpening mechanism, and the axial direction of the steel wire channelis parallel to the moving direction of the sharpening mechanism. According to the automatic sharpening machine, targeted synchronous grinding of a steel wire is realized, so that the processing efficiency of the steel wire is improved, and the grinding effect of the steel wire is improved.

Owner:ZHUJI HAINA SPECIAL STEEL

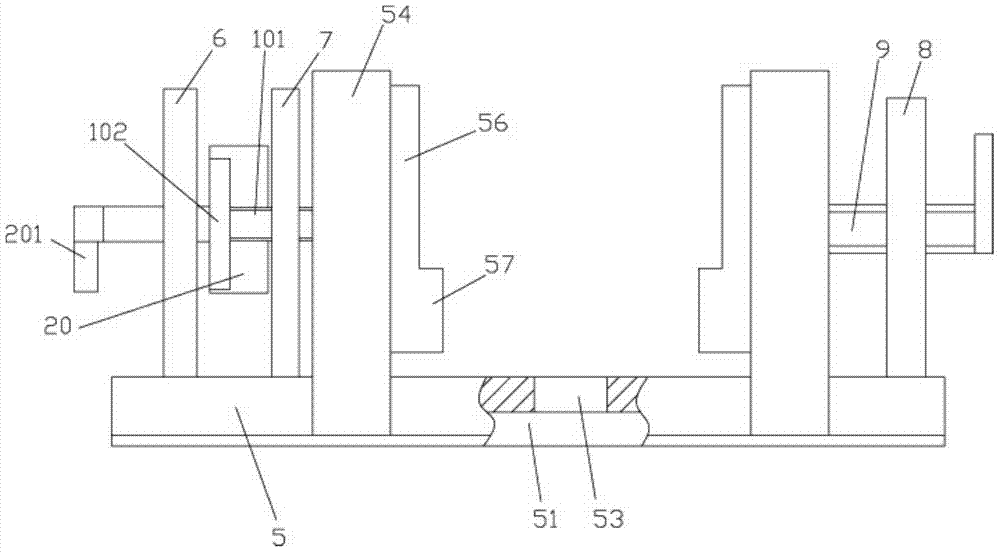

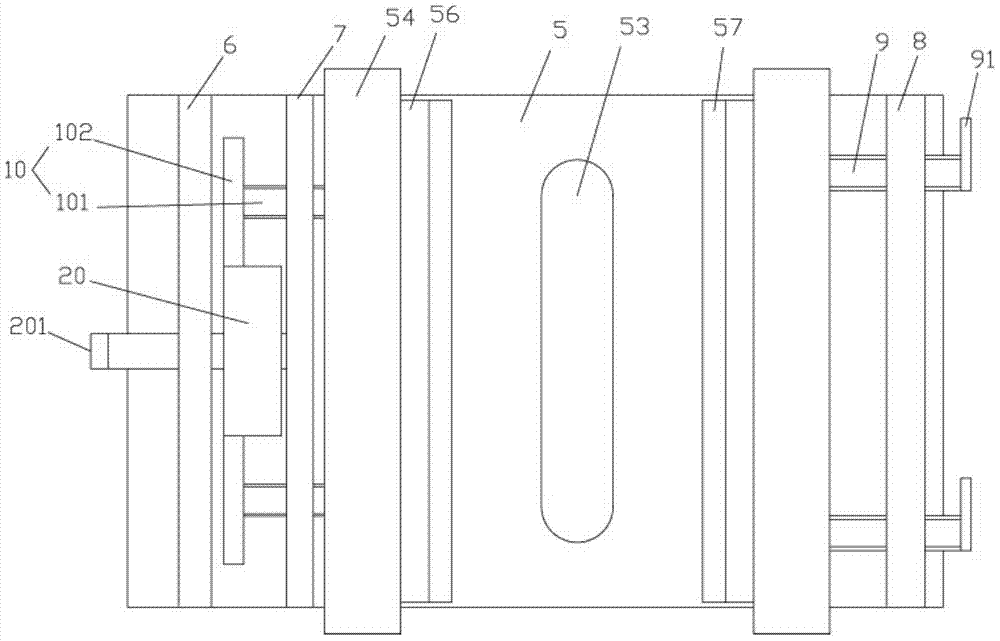

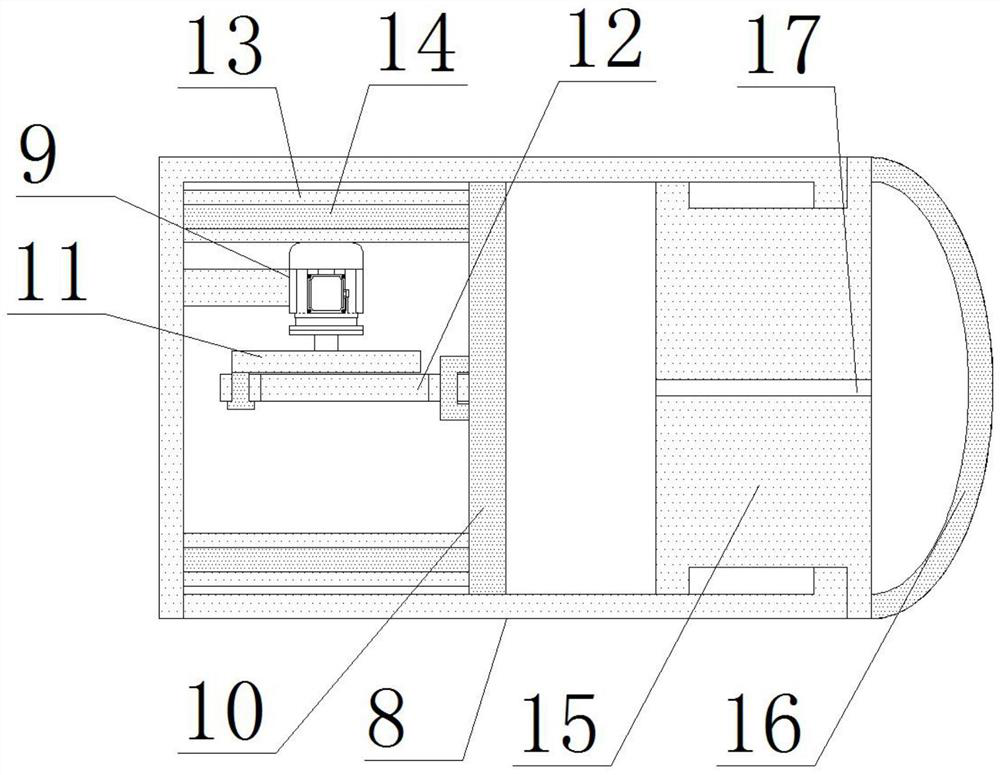

Rock hardness detection device based on geological exploration

InactiveCN112378799APrevent splashAvoid accidental injuryInvestigating material hardnessThreaded pipeGear wheel

The invention relates to the technical field of geological survey, in particular to a rock hardness detection device based on geological exploration. The device comprises a box body, a servo motor isfixedly installed at one end of the bottom of an inner cavity of the box body, a driving gear is fixedly installed on an output shaft of the servo motor, and a driven gear is engaged with the top of the driving gear; a positive and negative threaded rod is fixedly mounted on the inner side of the driven gear, and the outer side of the positive and negative threaded rod is in threaded connection with a threaded pipe; through the arrangement of the box body, the servo motor, the driving gear, the driven gear, the positive and negative threaded rods, the threaded pipe, a support plate and a protection frame, the problems that the existing rock hardness detection device does not have a protection function, and the whole process is directly exposed outside when the traditional rock hardness detection device detects the rock hardness, during detection, rock fragments are easily and directly sputtered to the body of a worker, so that the body of the worker is damaged are solved.

Owner:湖南达道新能源开发有限公司

Rear axle housing body of beach vehicle

InactiveCN101314394AAvoid stuck teethAvoid breaking and other phenomenaChain/belt transmissionAxle unitsAutomotive engineeringEngineering

Owner:力帆科技(集团)股份有限公司

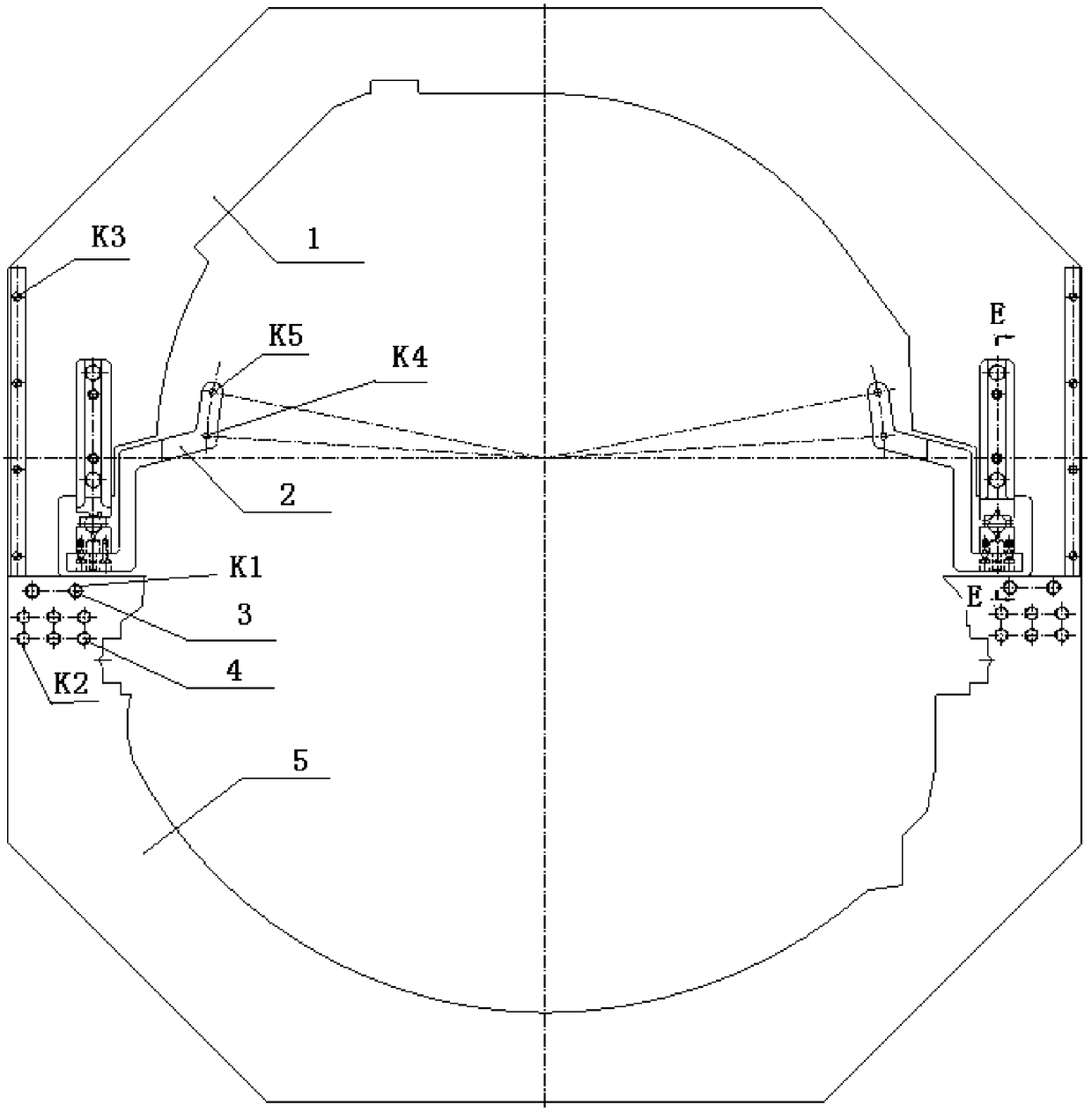

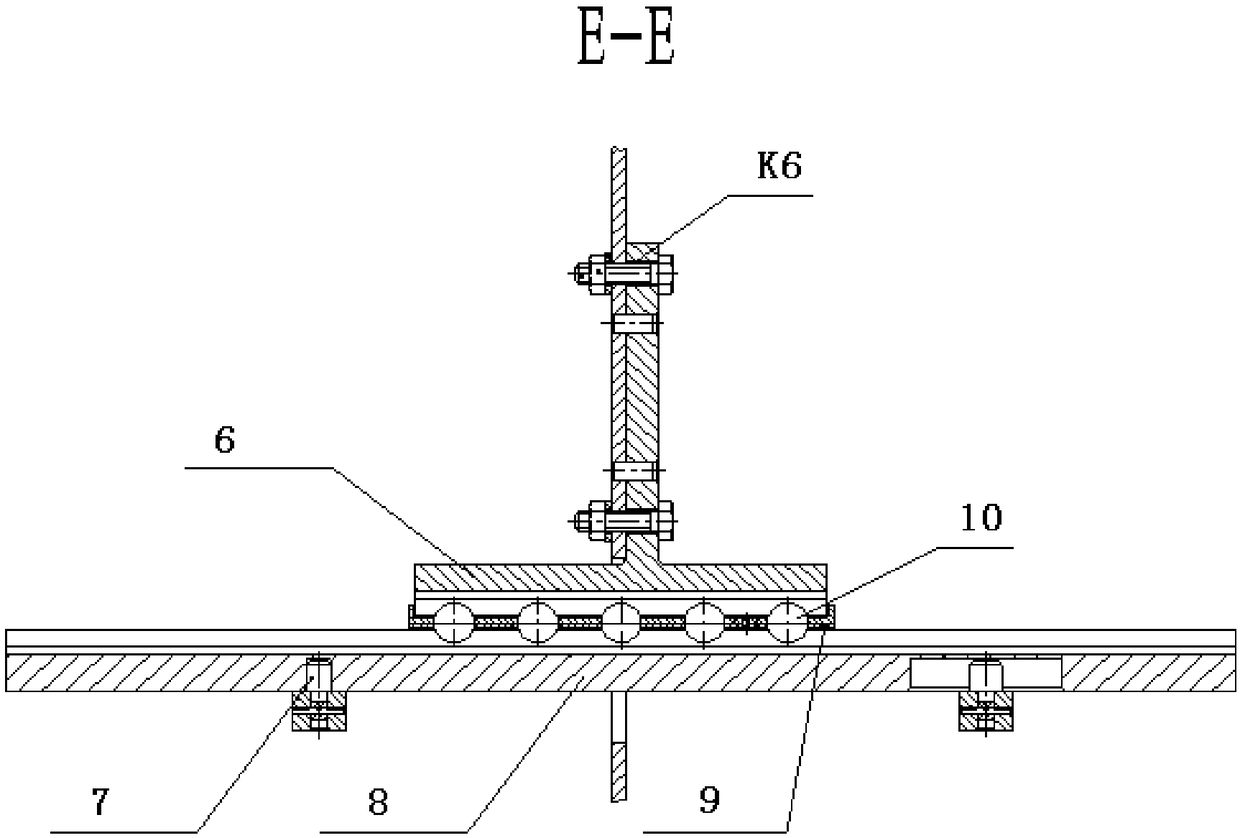

Contour detection method and contour detection device for aero-engine assembly

InactiveCN108278956AGuaranteed parallel movementEliminate human factorsMechanical counters/curvatures measurementsComputer scienceAero engine

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Automatic positioning device for battery cell tab

PendingCN110788474AHigh precisionImprove efficiencyFinal product manufactureWelding/cutting auxillary devicesEngineeringMechanical engineering

The invention provides an automatic positioning device for a battery cell tab, and relates to the field of lithium battery production. The automatic positioning device for the battery cell tab comprises an upper end socket, a lower end socket, a right clamping cylinder, a left clamping cylinder, a regulating valve, a correcting fixing plate, a forward and backward screw rod, a fine adjustment block, an up-down sliding plate, a forward and backward guide rail fixing plate, a linear guide rail, an up-down cylinder, a left fixing clamp, a right fixing clamp, a left opening spring, a spring supporting block, a right opening spring, a linear guide rail, a right clamp, a left clamp, a base, an aluminum mold and a bare battery cell, wherein the rear end of the upper end socket is movably connected with the lower end socket. According to the automatic positioning device for the battery cell tab, inert gas flows into the right clamping cylinder and the left clamping cylinder from the cylindersthrough pressure difference, flows into the central position from the cylinders, and pushes the left fixing clamp and the right fixing clamp to adjust the positions, and the right clamp and the left clamp are aligned with the tab position to clamp, so that the precision of battery cell tab folding and positioning is improved.

Owner:东莞赣锋电子有限公司

Building safety net cleaning device

InactiveCN112024478AImprove cleaning efficiencyPlay the role of conveying guideCleaning using toolsCleaning using liquidsEnvironmental resource managementSafety net

The invention discloses a building safety net cleaning device. The cleaning device comprises a box body, a feeding port, a feeding structure, an adjusting structure, a cleaning structure, a rotating screw rod, a water inlet pipe, a fixing sleeve, a water tank, spray heads, brushes, a fixing rod, conveying rollers, a guide structure, a discharging port and a water outlet pipe. The cleaning device has the beneficial effects that the multiple brushes are linearly distributed at the bottom end of the fixing sleeve, through the arrangement of the brushes, a steel mesh penetrating through the interior of the box body can be brushed, the multiple conveying rollers linearly rotate in the box body, the effect of supporting the steel mesh can be achieved, and the effect of conveying and guiding thesteel mesh can also be achieved, so as to cooperate with the brushes to have a better brushing effect. After external water enters into the water tank through the water inlet pipe, due to the fact that the water tank is communicated with the spray heads, the water in the water tank can enter the spray heads and then is sprayed out, and the brushes can be matched to brush dust and soil on the steelmesh. Therefore, brushing quality and efficiency can be greatly improved.

Owner:山东鼎鲁建筑工程有限公司

A workpiece clamping device with longitudinal movement of machine tool track

ActiveCN104476391BGuaranteed parallel movementGuaranteed service lifeHoning machinesGrinding work supportsEngineeringMachine tool

Owner:金丽丹

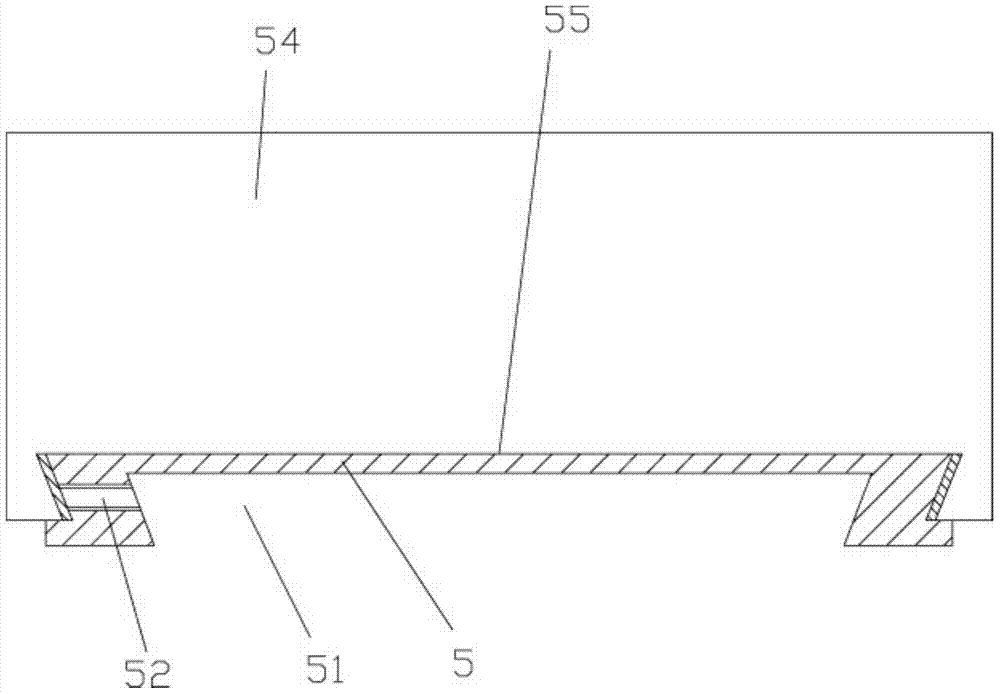

Flexible printing plate pasting device and method

PendingCN113968076AQuick pastePrecise alignmentPrinting press partsEngineeringMechanical engineering

Owner:BEIJING QUNYING PRINTING CO

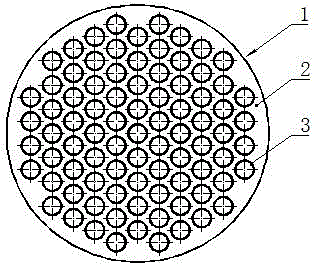

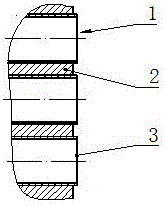

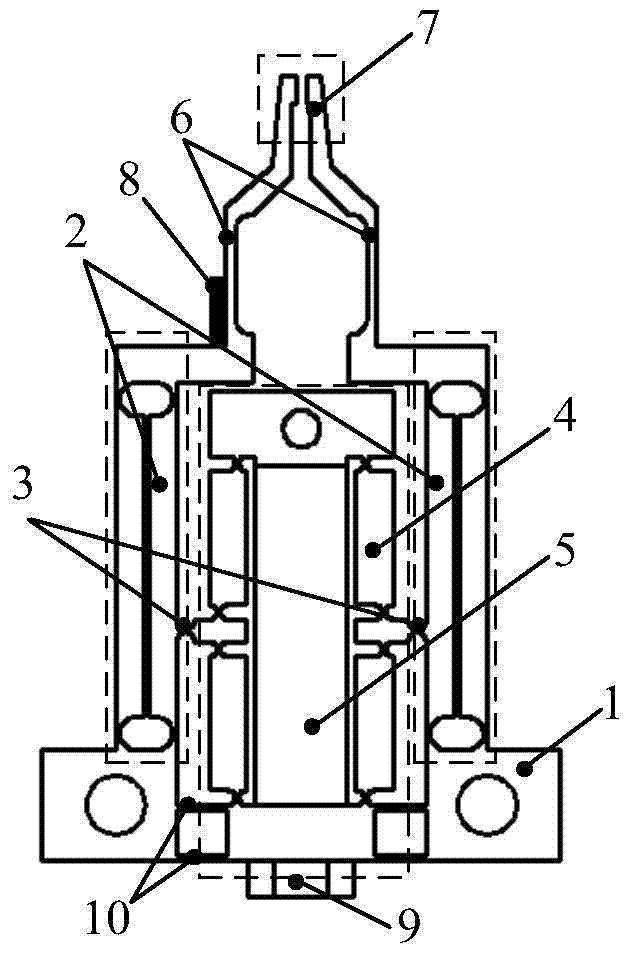

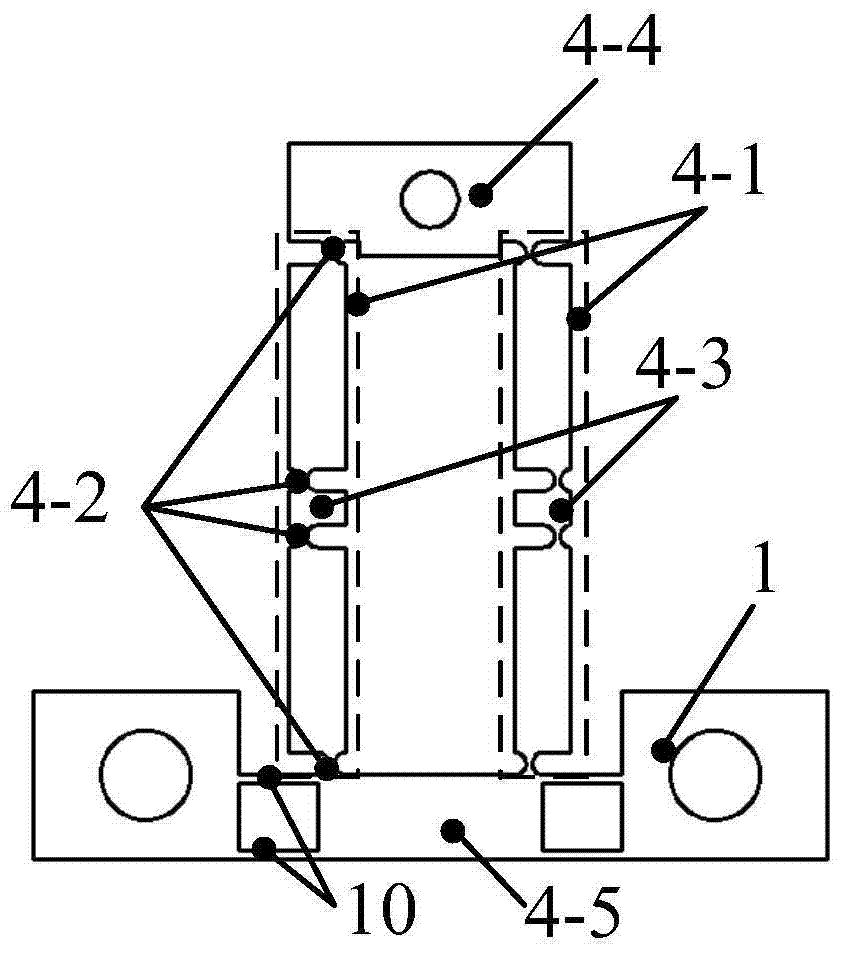

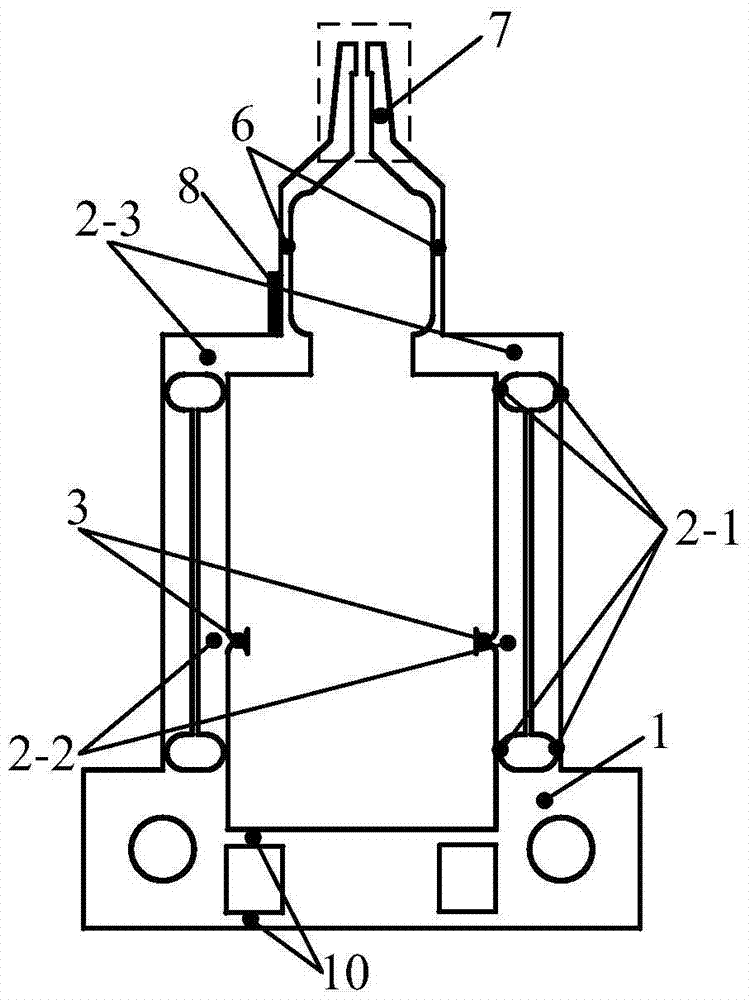

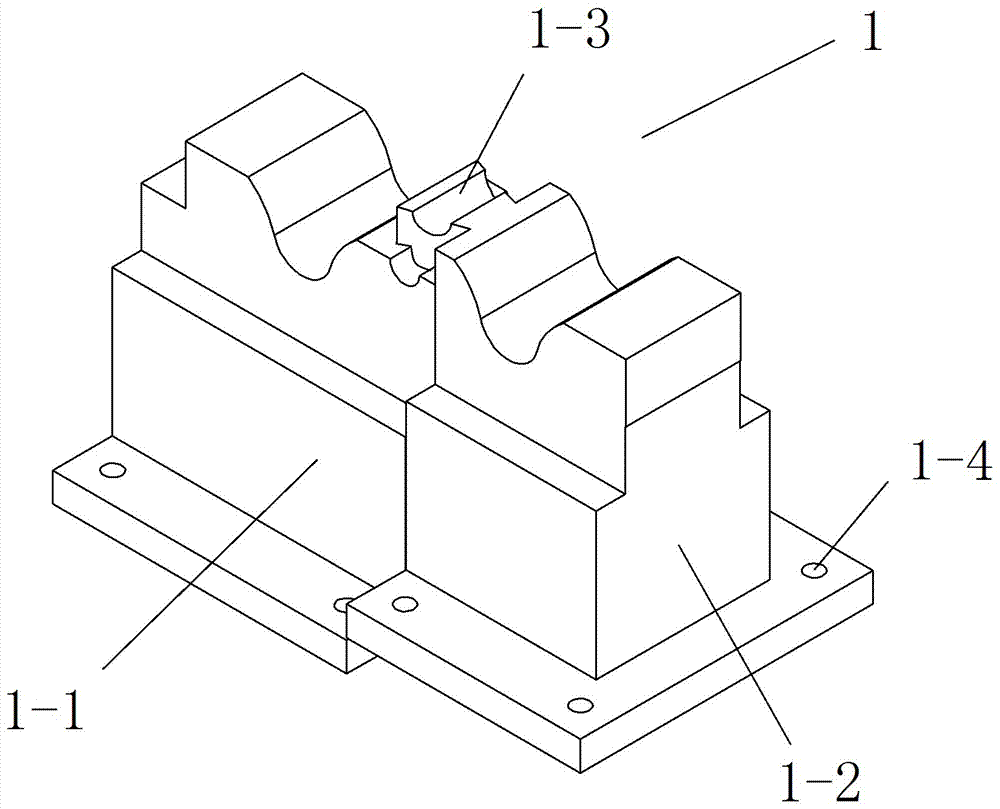

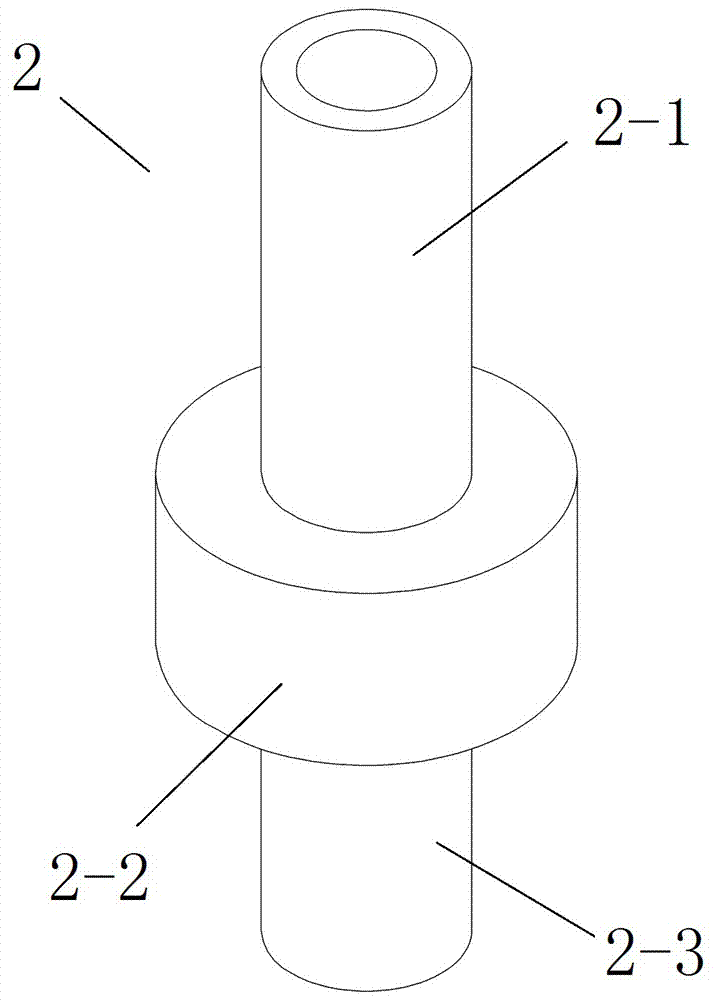

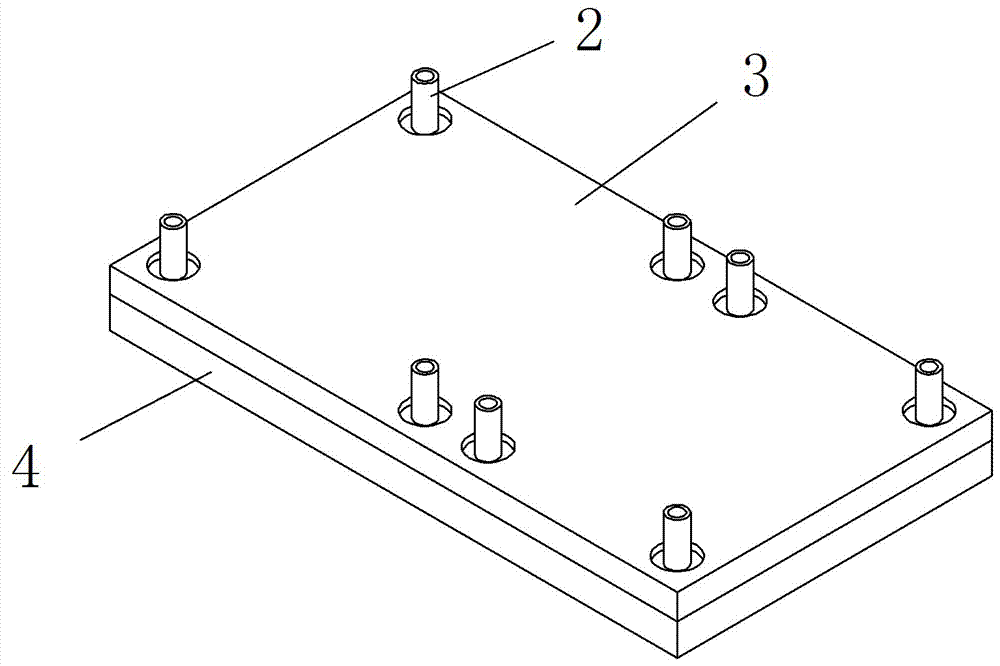

Piezoelectric driven high precision lead wire clamp

ActiveCN105236349BReduce quality problemsReduce volumeDecorative surface effectsChemical vapor deposition coatingElectricityPiezoelectric actuators

The invention discloses a piezoelectric-driven high-precision lead wire clip. The wire clip is integrally formed by wire cutting of a plate, and includes a bridge-type displacement amplification mechanism and a base body. The base body is formed on both sides of the movable end of the bridge-type displacement amplification mechanism. Side; the bridge-type displacement amplifying mechanism is provided with a fixed beam parallel to the substrate, a movable beam and two four-bar linkages connecting them, and a flexible parallel double-plate mechanism connected to the substrate is formed at both ends of the movable beam; A piezoelectric ceramic driver is provided between the fixed beam and the movable beam; two parallelogram mechanisms are formed on one side of the substrate, and a connecting beam perpendicular to it is formed on the output end of the parallelogram mechanism, and a connecting beam is formed on the connecting beam. There are jaws; the output end of the bridge-type displacement amplifying mechanism is connected with the input end of the parallelogram mechanism through a flexible hinge III. The invention has the advantages of small volume, compact structure, stable and reliable clamping force, low manufacturing cost and large displacement magnification.

Owner:TIANJIN UNIV

A workpiece clamping device for a machine tool track

ActiveCN104440546BGuaranteed parallel movementGuaranteed service lifeGrinding work supportsEngineeringMachine tool

The invention discloses a workpiece clamping device of a track of a machine tool. The workpiece clamping device of the track of the machine tool comprises a base plate and a longitudinal adjusting base plate, wherein a longitudinal moving groove is formed in the bottom of the base plate; an adjusting screw hole is formed in a side wall of the base plate; at least two transverse adjusting tracks are fixed on the top of the base plate; adjusting grooves which are matched with the adjusting tracks are formed in the bottom of an upper clamping adjusting block; the adjusting tracks are inserted in the adjusting grooves; supporting plates are fixed at the front end and the rear end of the base plate; two ends of an adjusting lead screw are hinged to the two supporting plates; the middle of the adjusting lead screw is in screwed connection to screwed connection through holes formed in the left side and the right side of the upper clamping adjusting block; a bottom chute is formed in the bottom of the longitudinal adjusting base plate; and a dovetail-shaped sliding track which is arranged on the upper portion of the upper clamping adjusting block is inserted in the bottom chute. Two adjusting gear screws move synchronously by rotating a middle adjusting gear, an adjusting clamping block on the left side can move in parallel, and workpieces can be quickly adjusted in the transverse direction and the longitudinal direction.

Owner:金丽丹

Obstacle collision early warning device based on vehicle-road cooperation

InactiveCN112537322AAvoid getting stuckAvoid missing informationDetection of traffic movementAnti-collision systemsDriving safetyElectric machinery

The invention provides an obstacle collision early warning device based on vehicle-road cooperation. The device comprises a display, a driving camera, an infrared sensor, a radar detector and a vibration sleeve, wherein one side of a display screen is provided with an intelligent processor through bolts, the top of the intelligent processor is provided with an information transmitter through bolts, the inner side of the display screen is provided with an alarm loudspeaker box through bolts, and the inner of the vibration sleeve is provided with a motor through bolts. According to the obstaclecollision early warning device based on vehicle-road cooperation, a rubber sleeve can be driven by a piston to vibrate back and forth on the inner side of a seat, information omission is avoided, thesituation that the piston collides with a person and pains the person can be prevented, and safety of the person is improved; the obstacle collision early warning device based on vehicle-road cooperation guarantees body safety of personnel, can relieve pushing of the piston and the rubber sleeve to the personnel through compressed air when the personnel are tightly attached to the seat backrest, guarantees comfort and driving safety of the personnel, effectively guarantees flatness and comfort of the seat backrest, and is suitable for being installed on an automobile to be used for obstacle collision early warning.

Owner:HUNAN INSTITUTE OF ENGINEERING

Welding mold, welding device and mold installation method for double-spout transfusion bag

The invention discloses a welding device and a welding method for a double-pipe transfusion bag. The welding device includes a welding mold, which is divided into two parts corresponding to the nozzle; the two parts are connected by a locking structure, so that the two parts of the mold run in the same direction during the welding process. The welding device of the double nozzle infusion bag of the present invention divides the welding mold into two parts, and connects the two parts through the locking structure, so as to ensure the parallel movement between each other; the elastic buffer pad is used to reduce the deviation of different nozzles due to material and size And it is difficult to match the impact, thus improving the quality of double nozzle welding. By setting the guide parts, the mold can maintain the correct relative position with the nozzle during the welding process, so as to avoid the deviation of the welding position of the nozzle.

Owner:HUNAN KELUN PHARMA

A glass wool product quality on-line monitoring device

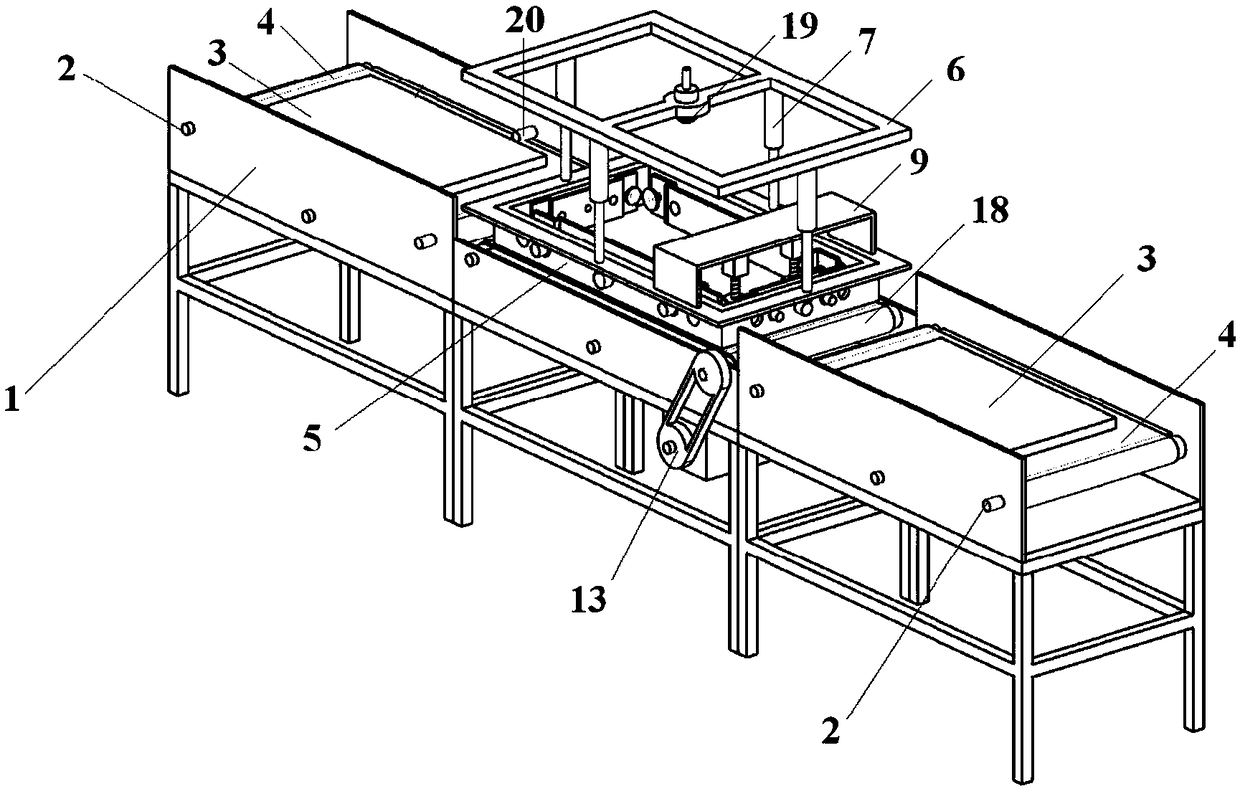

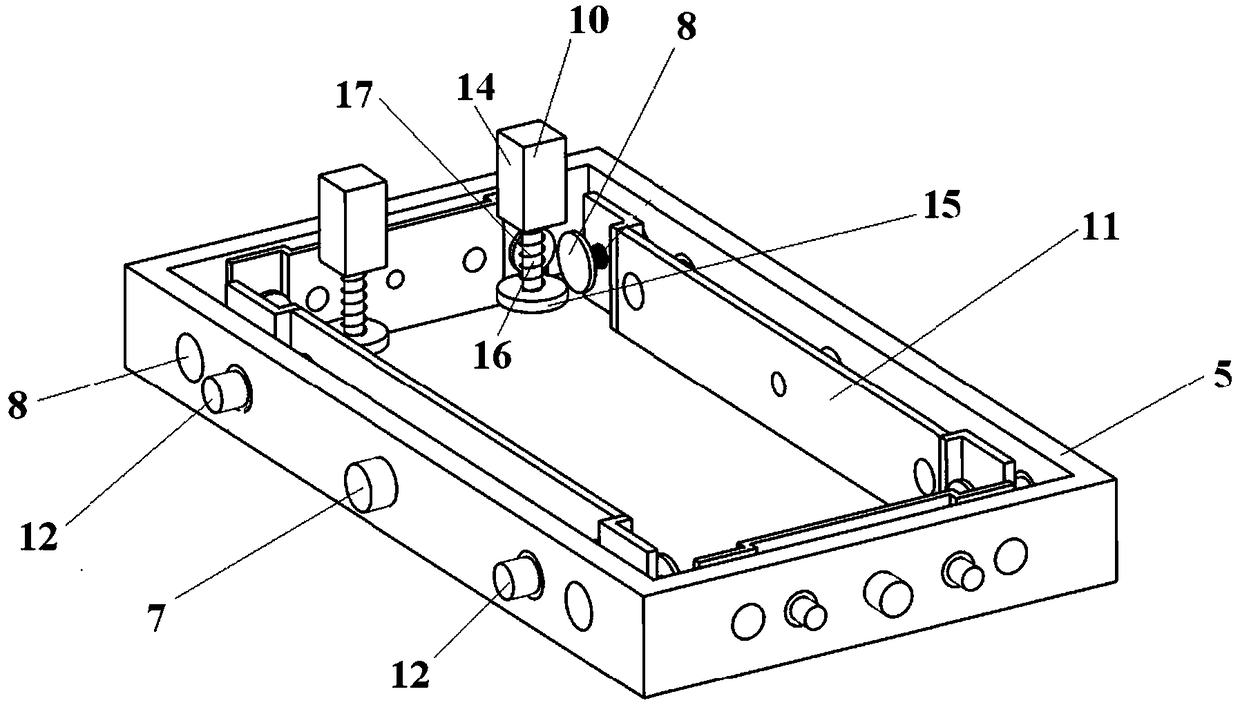

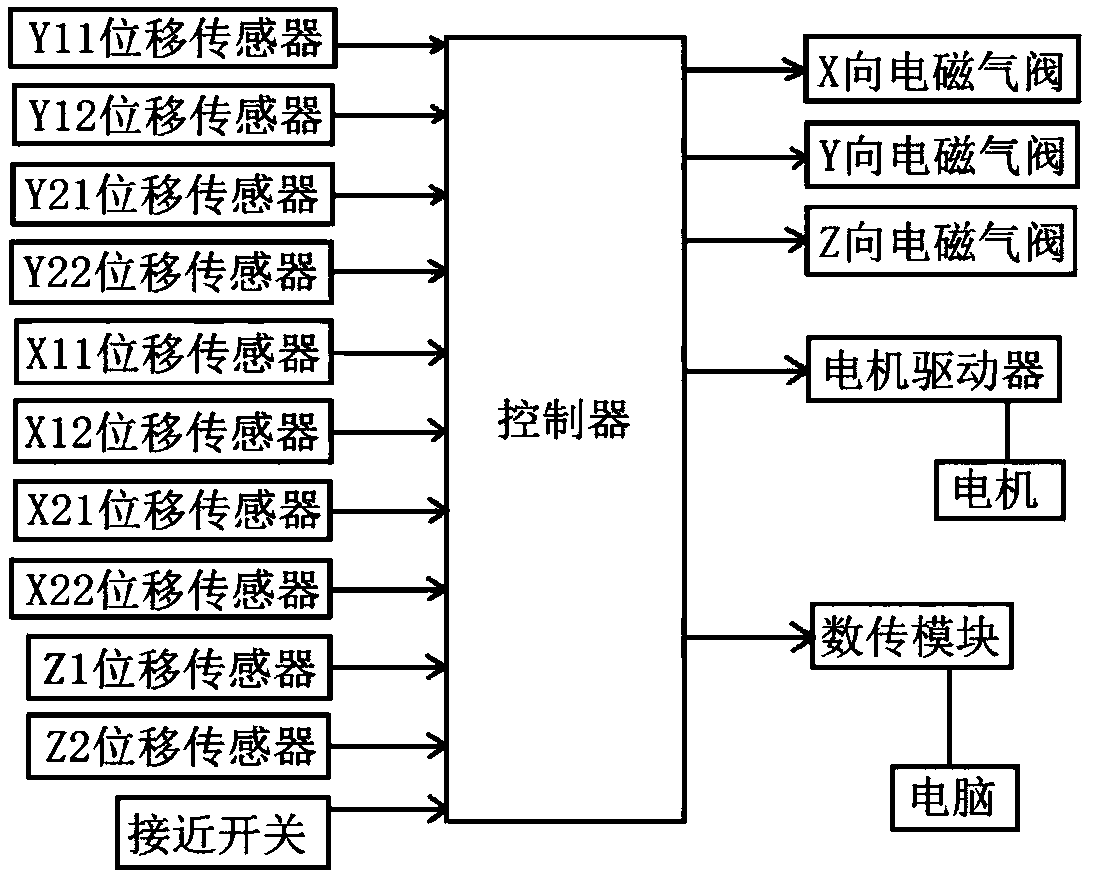

ActiveCN106225750BLarge telescoping rangeGuaranteed parallel movementMeasurement devicesProduction lineEngineering

The invention discloses an on-line glass wool product quality monitoring device, comprising a support, wherein roll shafts are installed between the side walls of two ends of the support, belts for conveying glass wool are arranged on the roll shafts, and a measuring mechanism is installed on the support and between the belts at two ends; the measuring mechanism comprises a rectangular frame, a support frame arranged above the rectangular frame and a cylinder for connecting the rectangular frame with the support frame; a plane displacement sensor extending inwards is respectively fixed at two ends of each side of the rectangular frame, a longitudinal support frame is fixed above the support frame and on the other side of the rectangular frame, and two thickness measuring displacement sensors extending to the rectangular frame are fixed on the longitudinal support frame at interval; a baffle is arranged inside each edge of the rectangular frame, the baffles are movably connected with the rectangular frame via guide rods, and the baffles are also connected with the cylinder and the plane displacement sensors. The device is suitable for detecting glass wool on a production line on line, is high in detection speed and precision, and can discover problems in time and pick rejected products out.

Owner:HUBEI JIA FU DA ENERGY SAVING TECH CO LTD

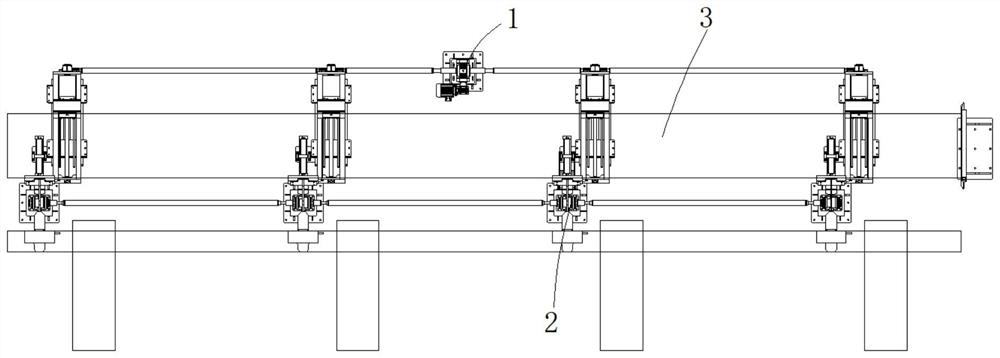

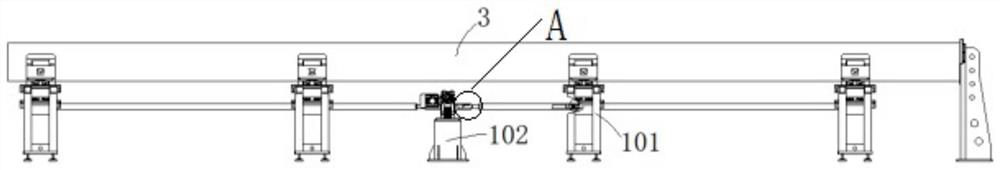

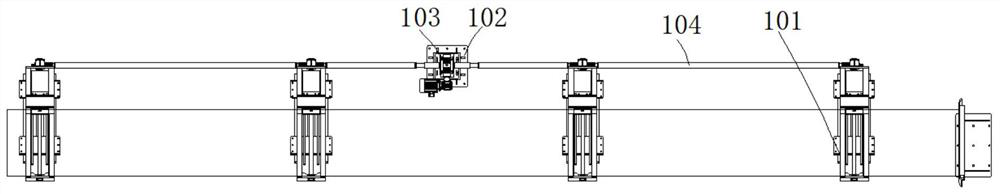

Crossbeam moving mechanism of novel box covering machine

ActiveCN104527132AGuaranteed parallel movementNot easy to cause big and small mouth problemsBox making operationsPaper-makingSmall deviationsEngineering

The invention relates to the technical field of a box covering machine, and in particular relates to a crossbeam moving mechanism of a novel box covering machine. The crossbeam moving mechanism of the novel box covering machine comprises a lower girder and an upper girder, a rear end motor is arranged at the rear end of the box covering machine, the rear end motor is connected with the rear end of the lower girder through the rear end transmission mechanism, a front end motor is arranged at the front end of the box covering machine, the front end motor is respectively connected with the front ends of the lower girder and the upper girder through the front end transmission mechanism. The crossbeam parallel movement can be effectively guaranteed, the front end motor or the rear end motor can be independently adjusted while the crossbeam movement has small deviation or the movement distance of each of the front and rear ends is different. The movement distance of the front end and the rear end of the crossbeam can be guaranteed for the same and the paperboard is not easy to have big and small openings.

Owner:GUANGDONG DONGFANG PRECISION SCI & TECH CO LTD

Fixed support for pump stroke sensor, and pump stroke sensor with fixed support

PendingCN109707617AEasy to installEasy to disassemblePump testingPositive displacement pump componentsEngineering

The invention discloses a fixed support for a pump stroke sensor. The fixed support for the pump stroke sensor comprises an installation plate used for installing the pump stroke sensor, a horizontaladjustment mechanism used for adjusting a horizontal direction position of the installation plate, a vertical adjustment mechanism used for adjusting a vertical direction position of the installationplate, and a clamping mechanism used for fixing the installation plate, wherein the horizontal adjustment mechanism, the vertical adjustment mechanism and the clamping mechanism are connected with theinstallation plate. The invention further discloses a pump stroke sensor with the fixed support. The pump stroke sensor with the fixed support comprises a pump stroke sensor body fixed to the fixed support, a clamping element and an extension rod used for transferring a pump stroke, wherein the pump stroke sensor body is connected with the extension rod through the clamping element. The fixed support for the pump stroke sensor, and the pump stroke sensor with the fixed support are capable of effectively adjusting the height and the direction of the sensor; and in this way, use for the sensorcan be facilitated, and working personnel are facilitated to observe and record the data of the sensor.

Owner:北京迈斯康特测控技术有限公司

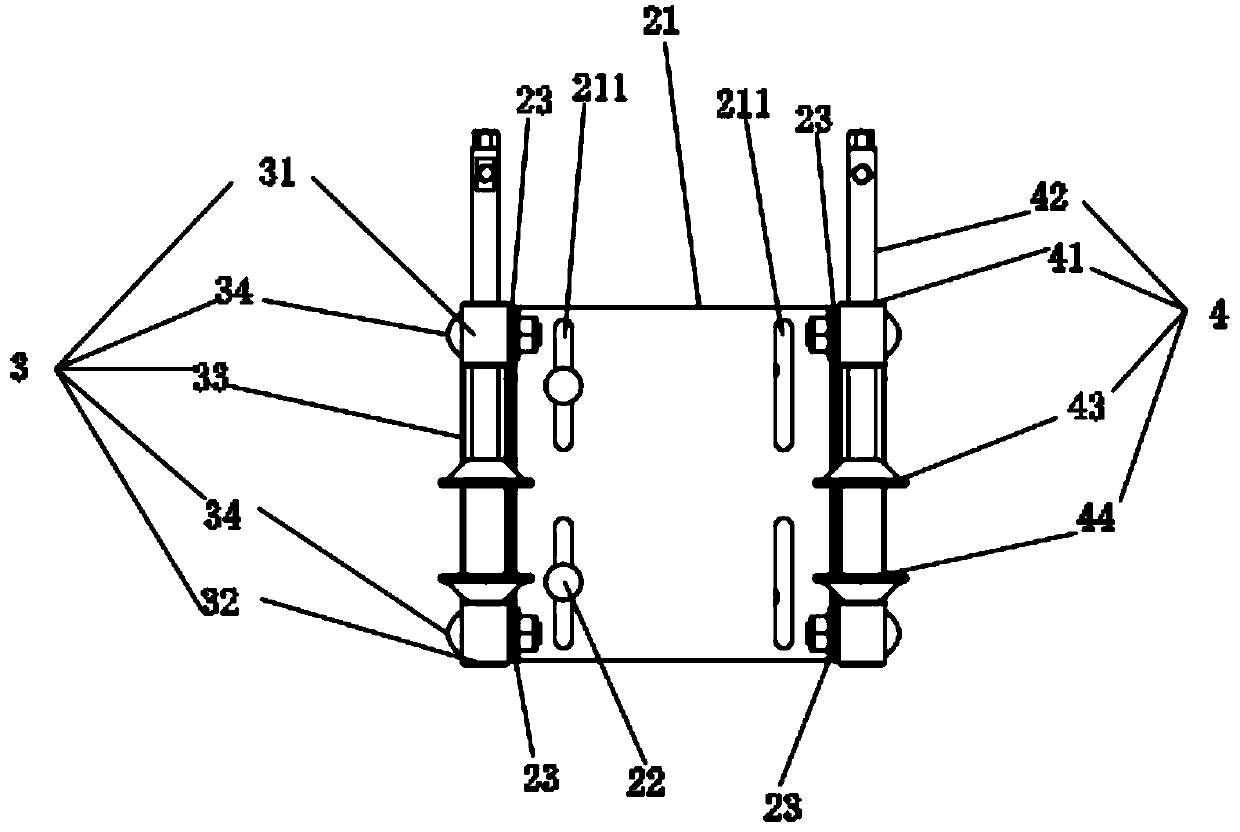

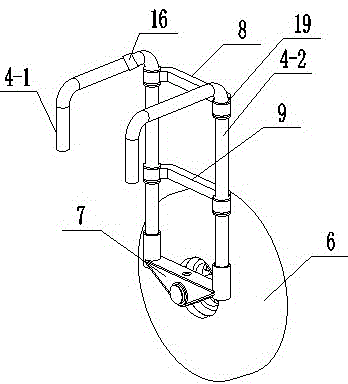

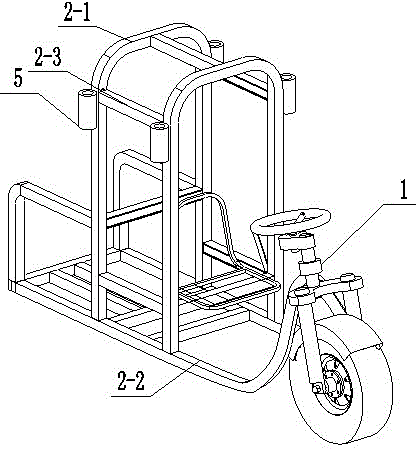

Traction-powered chassis for high-stalk crops

ActiveCN103109607BGuaranteed stabilityIncrease flexibilityAgricultural undercarriagesVehicle frameAgricultural engineering

The invention provides a traction power chassis suitable for tall-stem crop farm machinery operation, and relates to the technical field of agricultural machines and tools. The traction power chassis comprises a vehicle head front wheel assembly, a vehicle frame assembly, a power system and side wheel assemblies. The side wheel assemblies are connected with the vehicle frame assembly, side wheels are installed on the side wheel assemblies which are arranged on side faces of the vehicle frame assembly, wing swinging assemblies on the side wheel assemblies extend upwards and then are bent towards the direction of the vehicle frame assembly, bending ends of the wing swinging assemblies are connected with the vehicle frame assembly, and an area formed in an enclosing mode by the wing swinging assemblies and the vehicle frame assembly after connection serves as a space for tall-stem crops to pass through. Compared with the prior art, when the traction power chassis passes on a tall-stem crop planting field, the tall-stem crops can pass from under swinging wings, and the crops are not damaged; and after different agricultural tools are assembled on the chassis, planting, hilling, fertilizing, pesticide spraying, harvesting and other working procedures can be carried out on two rows of tall-stem crops simultaneously, the left wing and the right wing rotates to change wheel tread, and therefore the traction power chassis is suitable for fields with different ridging spacing.

Owner:LIUZHOU BOSHIWEI AUTOMOBILE TECH

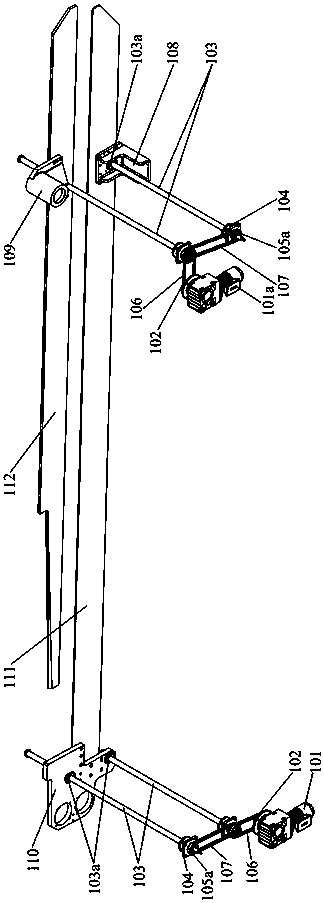

Wire-arranging mechanism of multi-head wire-rewinding machine

InactiveCN101863398BReduce distractionsReduce parallel movementFilament handlingNumerical controlManufacturing cost reduction

The invention relates to the field of wire-arranging technology of a multi-head wire-rewinding machine, in particular to a wire-arranging mechanism of the multi-head wire-rewinding machine and a numerical control wire-arranging method. The wire-arranging mechanism of the multi-head wire-rewinding machine comprises a stander, a PLC controller, a screw rod driving device, wire-arranging guide wheels, a reversing guide wheel and a wire-arranging guide wheel driving device, wherein the wire-arranging guide wheel driving device is connected with the wire-arranging guide wheels; the screw rod driving device comprises a screw rod, a screw rod nut, an approach switch, two screw rod bearing seats, two synchronous belt pulleys, a synchronous belt and a constant speed motor, wherein the screw rod nut is connected with the wire-arranging guide wheel driving device; the PLC controller is connected with the approach switch and the constant speed motor; and the PLC controller is provided with a forward rotation monitoring timer, a reverse rotating monitoring timer, a millisecond-level reversing timer and a speed increasing and reducing timer. The invention not only reduces the interference amongwires and the production accidents and improves the wire-arranging quality and finished product wire quality, but also simplifies the structure, is easy for operation and reduces the manufacturing and maintaining costs.

Owner:东莞市康汇聚线材科技有限公司

A New Girder Moving Mechanism of Folder Gluer

ActiveCN104527132BGuaranteed parallel movementNot easy to cause big and small mouth problemsBox making operationsPaper-makingCardboardElectric machinery

The present invention relates to the technical field of the folder gluer, more specifically, relates to a new type of beam moving mechanism of the folder gluer. A new girder moving mechanism of a box gluer, including a lower beam and an upper beam. The rear end of the box gluer is equipped with a rear motor, which is connected to the rear end of the lower beam through a rear transmission mechanism. The front end is provided with a front-end motor, and the front-end motor is respectively connected with the front ends of the lower beam and the upper beam through the front-end transmission mechanism. The invention can effectively ensure the parallel movement of the girder. When the girder moves with a slight deviation or the distance between the front end and the rear end of the girder is required to be slightly different, the front end motor or the rear end motor can be individually adjusted to achieve this. It can ensure that the front end of the girder and the rear end of the girder move at the same distance when the girder moves, and it is not easy to cause the problem of the size of the cardboard.

Owner:GUANGDONG DONGFANG PRECISION SCI & TECH CO LTD

Automatic pavement cleaner for leveling road surfaces

ActiveCN107022964BPrevent jumpingGuaranteed parallel movementRoad cleaningVertical planeClassical mechanics

Owner:吴大汉

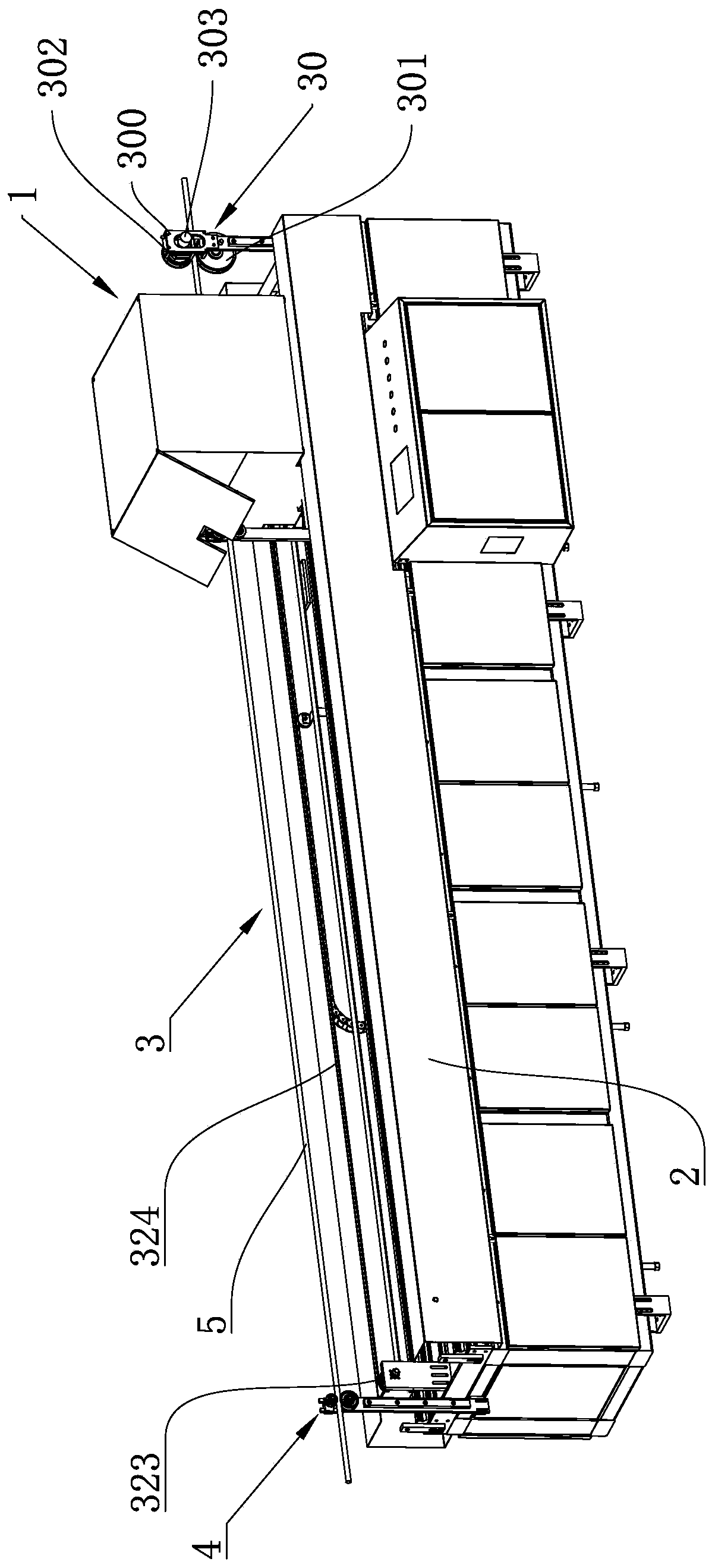

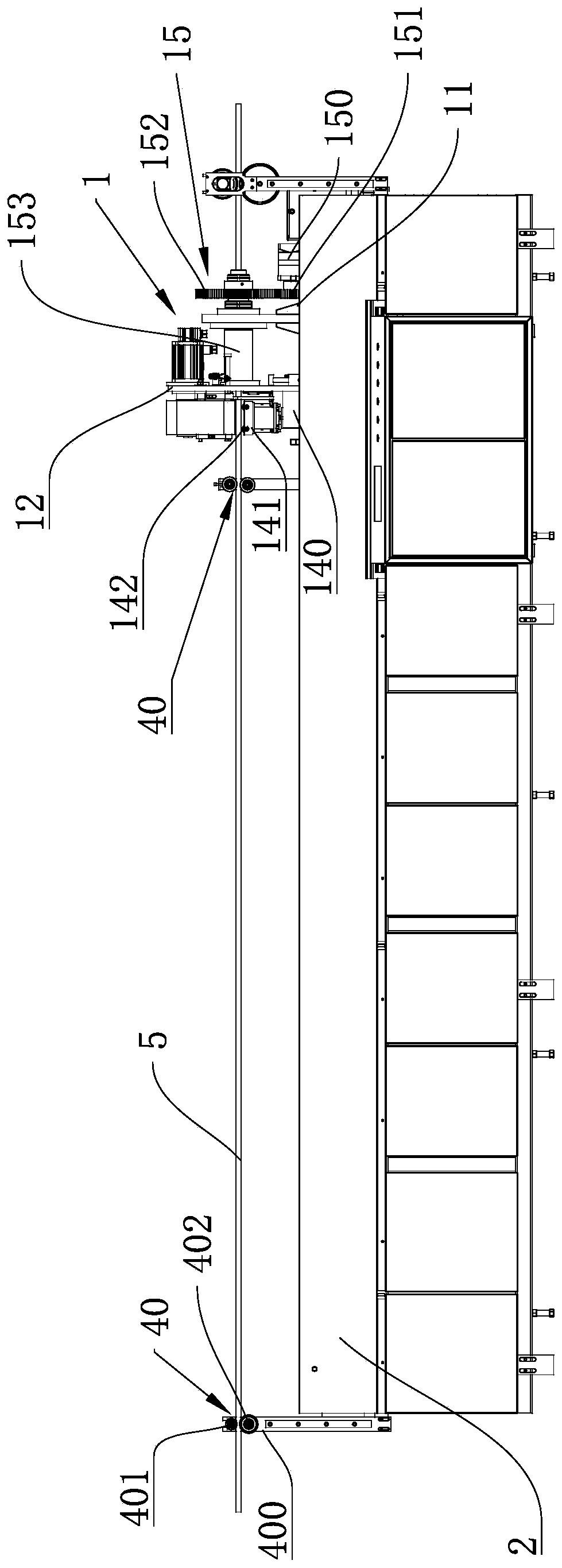

Feeding and sorting equipment

The invention relates to the technical field of slender plate processing, in particular to feeding and sorting equipment. The equipment comprises a feeding assembly, a grabbing assembly and a conveying line, the feeding assembly is fixedly connected to the back face of the conveying line, the grabbing assembly is fixedly connected to the front face of the conveying line, the grabbing assembly comprises a grabbing base, and a rotary support is arranged at the top of the grabbing base. Mounted bearings are embedded into the two sides of the interior of the rotary support, and rotary mandrels are fixedly inserted into inner rings of the mounted bearings. An air cylinder pushes a rotary arm to rotate anticlockwise, so that electromagnets make contact with a workpiece, the electromagnets are powered on to generate magnetism to suck the workpiece, the air cylinder returns to pull the rotary arm to rotate clockwise, the top of the conveying line can be conveyed to an external conveying line through the workpiece, discharging operation in slender plate machining is facilitated, the multiple electromagnets synchronously conduct adsorbing and discharging, the phenomenon of bending deformation of a slender plate due to low rigidity of the single workpiece in the discharging process can be effectively avoided, and the processing quality of the slender plate is ensured.

Owner:无锡洲翔成套焊接设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com