Flexible printing plate pasting device and method

A sticking device and flexible technology, used in printing, printing machines, general parts of printing machinery, etc., can solve problems affecting the sticking efficiency of flexographic printing plates, and achieve the effect of improving measurement accuracy and reducing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

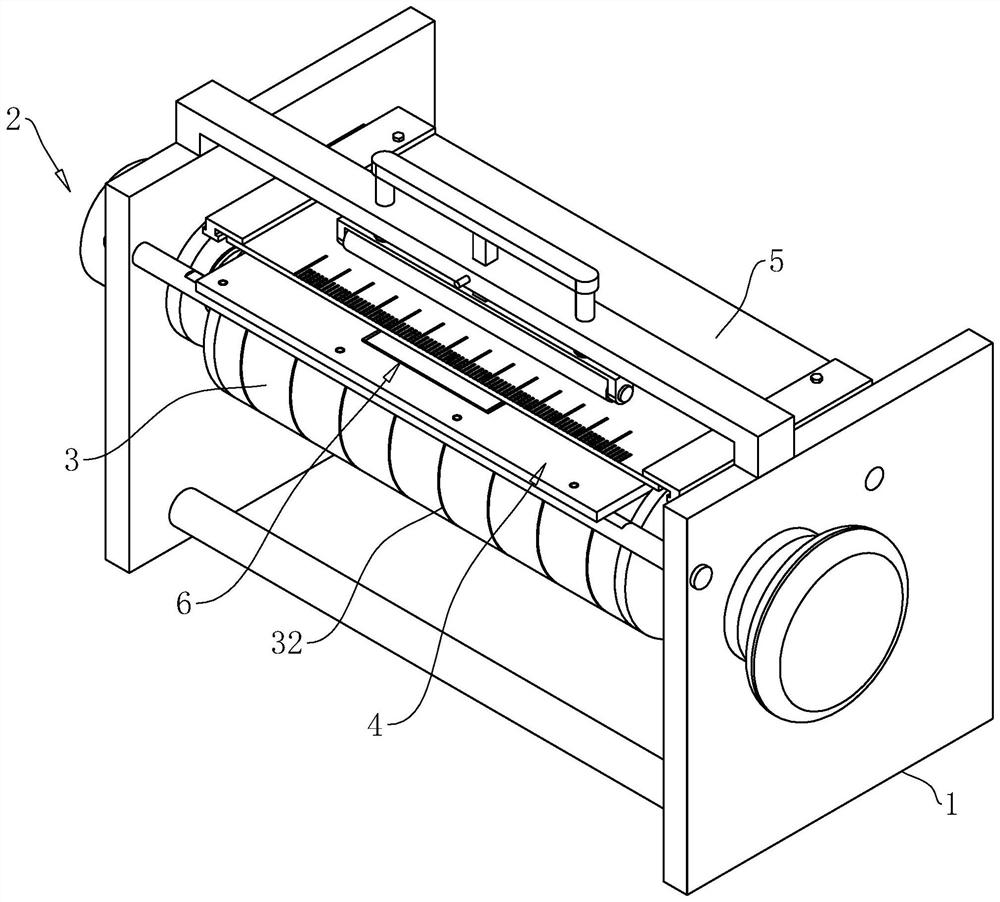

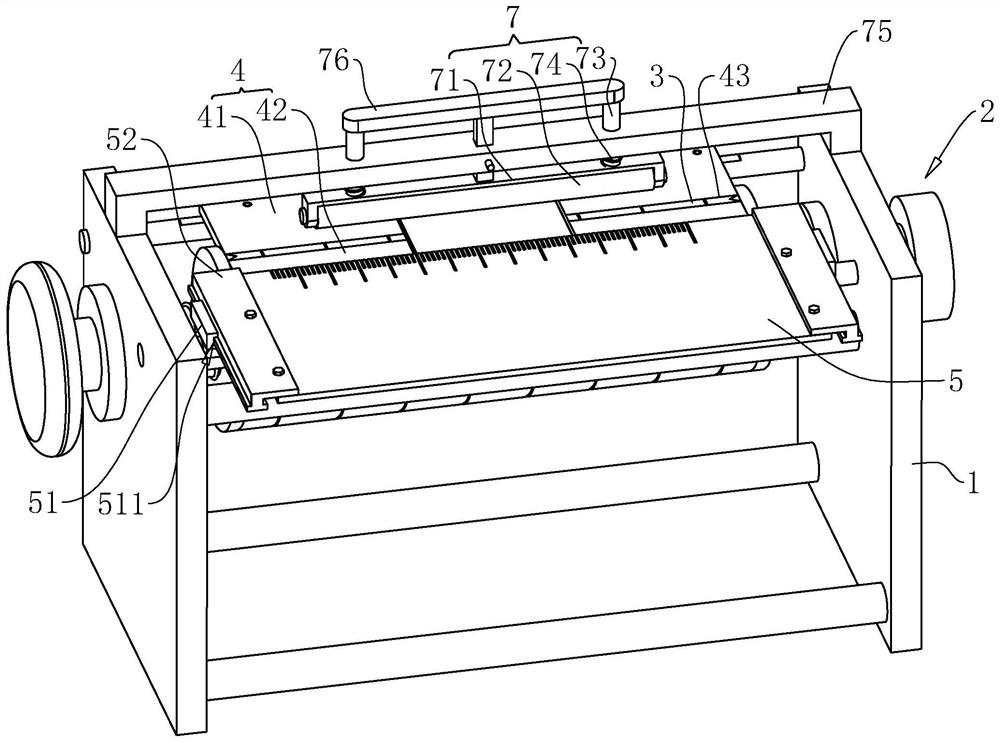

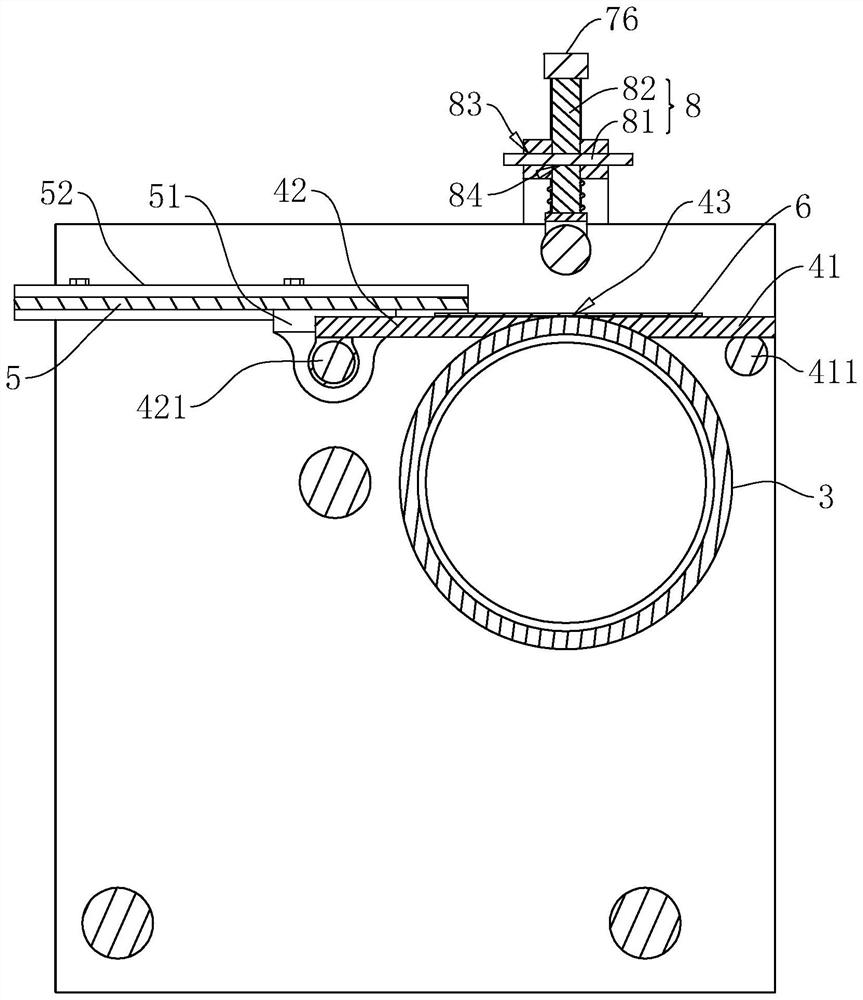

[0043] A flexible printing plate sticking device, refer to figure 1 , including a frame 1, on which a rotating assembly 2 for installing a printing roller 3 is arranged, when the printing roller 3 is mounted on the frame 1 through the rotating assembly 2, the axis of the printing roller 3 is set horizontally. A platform 4 for placing a flexographic printing plate 6 is provided on the frame 1, and the platform 4 is horizontally arranged at a position flush with the upper part of the printing roller 3, and an alignment ruler 5 is arranged parallel to the top of the platform 4, and the alignment ruler 5 slides horizontally Attached to rack 1. During use, the flexographic printing plate 6 is first placed on the platform 4, then the position of the flexographic printing plate 6 relative to the printing roller 3 can be adjusted, so that the alignment ruler 5 will measure the position of the printing printing plate on the platform 4, and by aligning The sliding of the ruler 5 measu...

Embodiment 2

[0052] A flexible printing plate sticking device, refer to Figure 6 The difference with Embodiment 1 is that the positioning assembly 8 includes a positioning screw 85, the length direction of the positioning screw 85 is arranged parallel to the guide rod 73, and the positioning screw 85 penetrates through the connecting piece 76 and is threadedly connected with the connecting piece 76, and the positioning screw 85 The lower end is used to abut against the beam body 74 . When the positioning screw 85 is rotated, the lower pressing roller 72 can move up or down, so that the lower pressing roller 72 can be positioned at a position away from the printing roller 3, and when the lower end of the positioning screw 85 breaks away from the beam body 74, the lower pressing roller 72 It can keep in contact with the printing roller 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com