Rear axle housing body of beach vehicle

An ATV and shell technology, which is applied to axles, wheels, vehicle parts, etc., can solve problems such as pull-off, chain jamming, and heavy rear axle housing, so as to extend service life, avoid chain jamming, and ensure performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

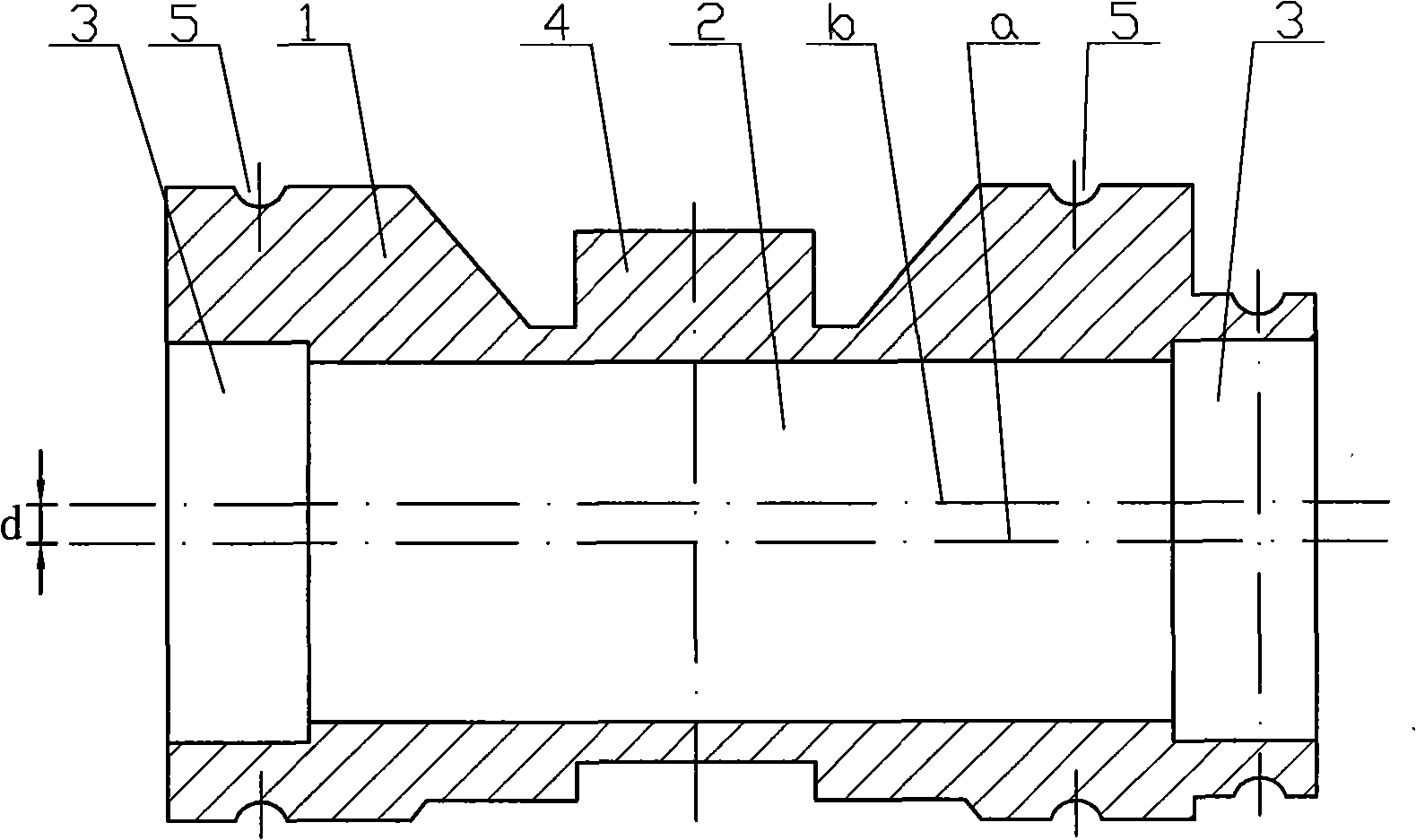

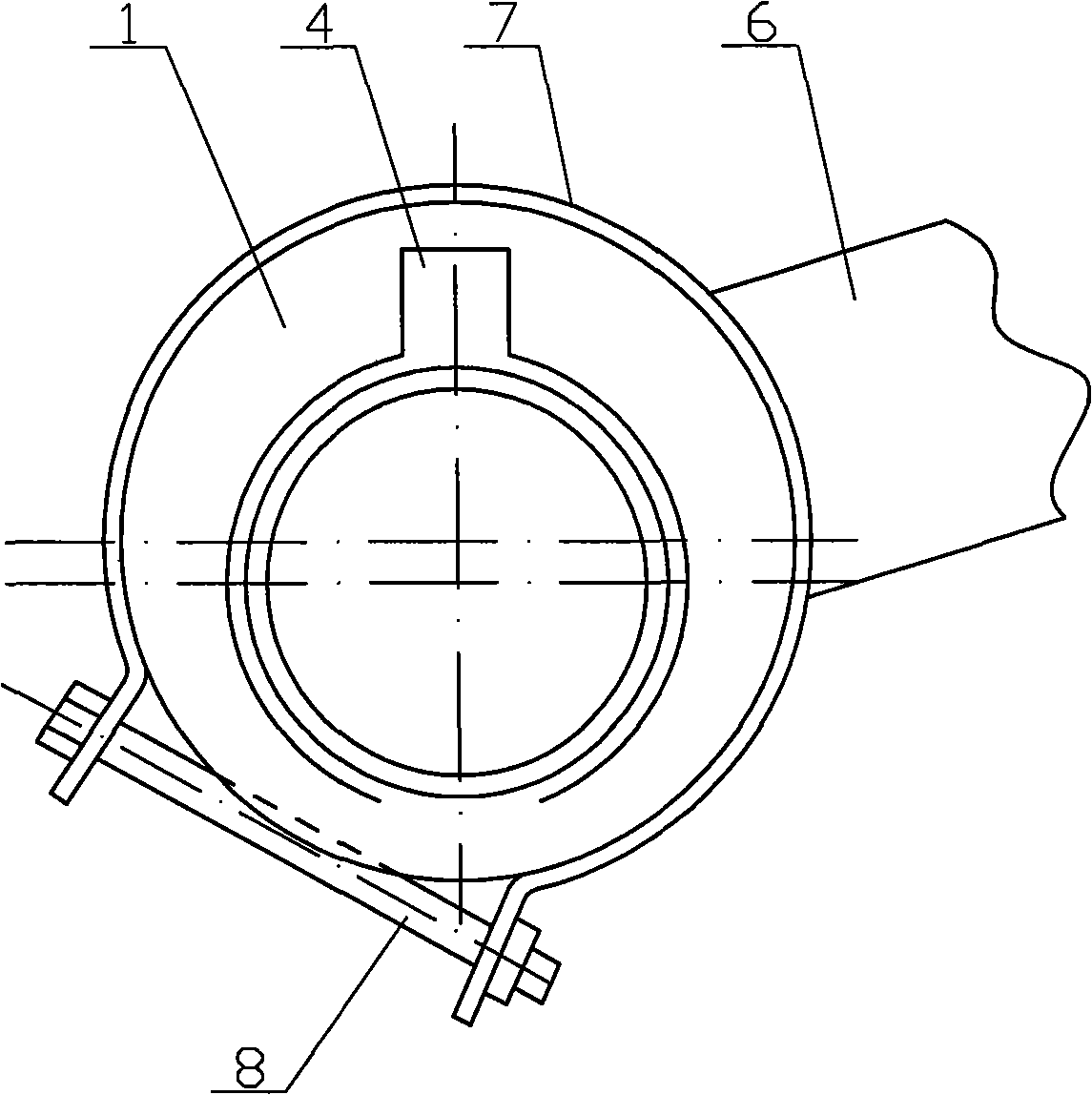

[0014] Such as figure 1 As shown, the rear axle housing 1 in the present invention is provided with a rear wheel shaft through hole 2 passing through its left and right end faces. The rear wheel shaft through hole 2 is a stepped hole with two large ends and a small middle, and the larger parts at both ends are bearings. Hole 3 for mounting bearings. The center line of the bearing hole 3 coincides with the center line a of the rear wheel shaft through hole 2, while the center line a of the rear wheel shaft through hole 2 deviates from the axis b of the rear axle housing 1 and is aligned with the axis line of the rear axle housing 1. b parallel. The deviation distance d between the center line a of the rear wheel shaft through hole 2 and the axis b of the rear axle housing 1 is 1-14 mm. An adjusting boss 4 is integrally formed in the middle of the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com