Piezoelectric driven high precision lead wire clamp

A piezoelectric driven, high-precision technology, used in decorative arts, gaseous chemical plating, microstructure technology, etc., can solve the problems of difficult to stabilize and control the clamping force, complex force calibration process, etc., to achieve the realization of the clamping force. The effect of measurement and feedback, reducing overall mass and motion inertia, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

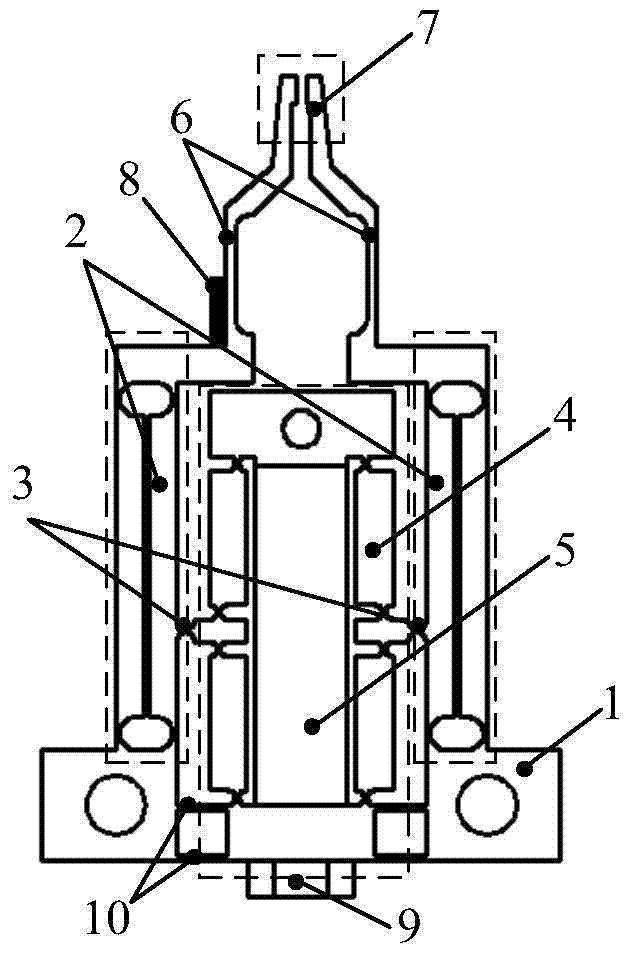

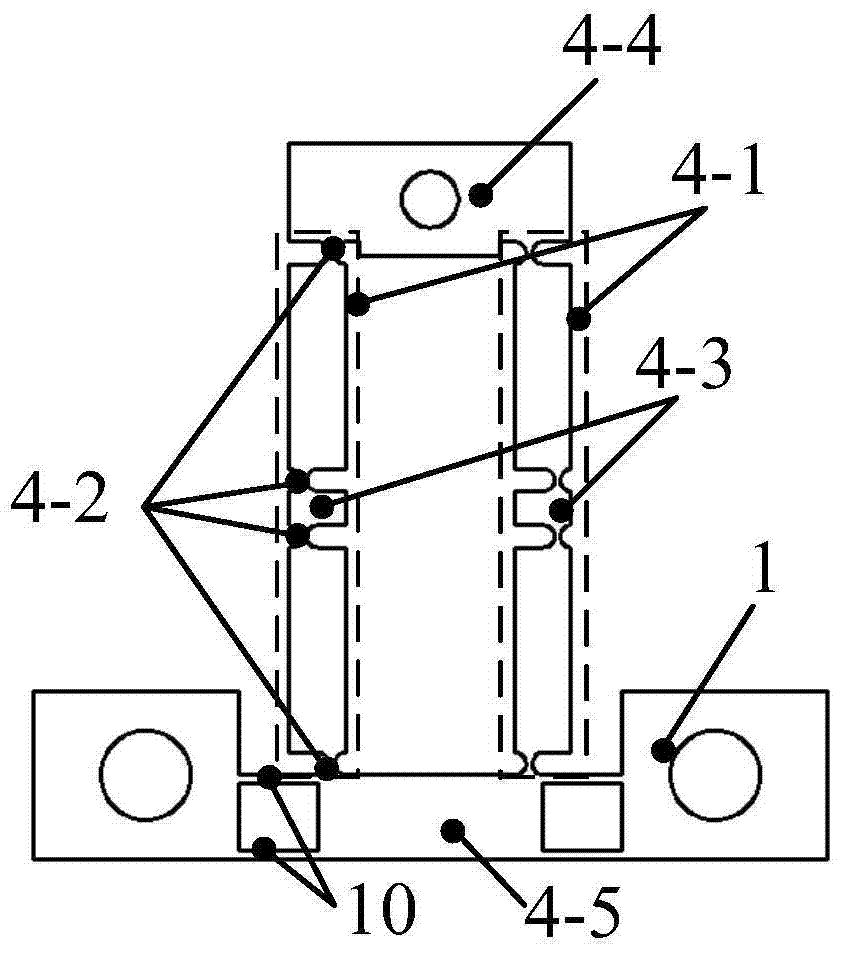

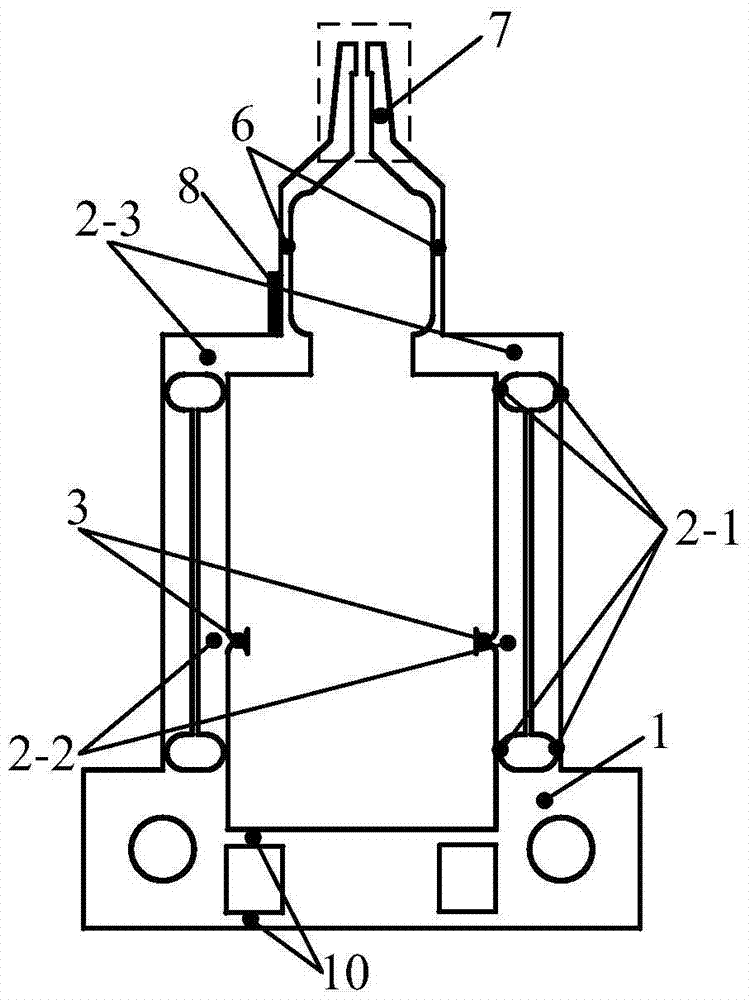

[0017] see Figure 1 to Figure 5 , a piezoelectric-driven high-precision lead clamp, which is integrally formed by plate wire cutting, and includes a bridge-type displacement amplification mechanism 4 and a base body 1, and the bridge-type displacement amplification mechanism 4 and the base body 1 are both Arranged symmetrically with respect to the center line of the clamp, the base body 1 is formed on both sides of the movable end of the bridge-type displacement amplifying mechanism 4 .

[0018] The bridge-type displacement amplifying mechanism 4 is provided with a fixed beam 4-4 parallel to the substrate 1, a movable beam 4-5, and two bridges connecting the fixed beam 4-4 and the movable beam 4-5. The four-bar linkage mechanism 4-1, the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com