A workpiece clamping device for a machine tool track

A workpiece clamp and track technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of reducing production efficiency, decreasing the effect, increasing the difficulty of adjustment, etc., and achieves the effect of improving production efficiency, ensuring service life, and adjusting quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

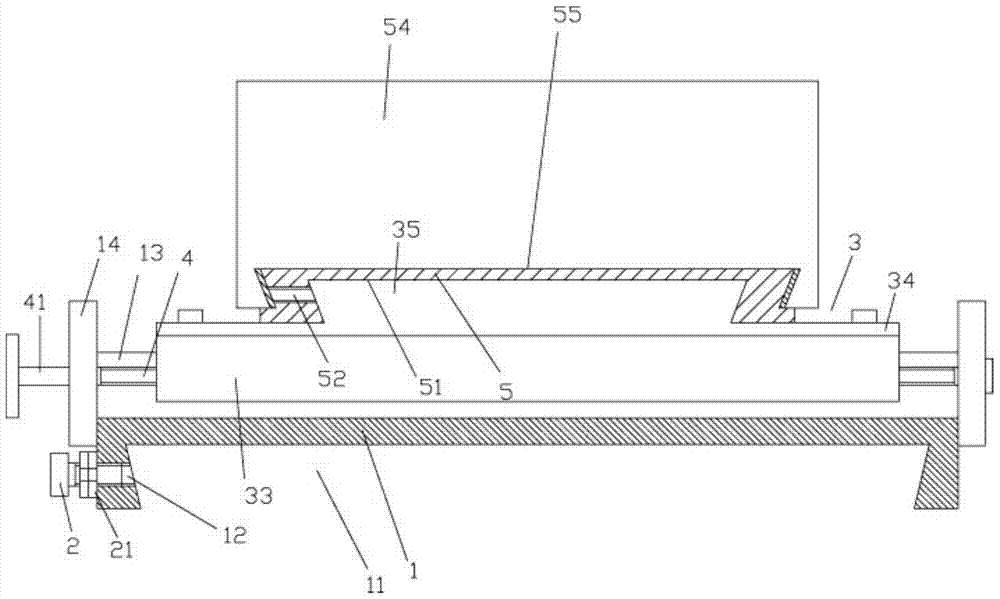

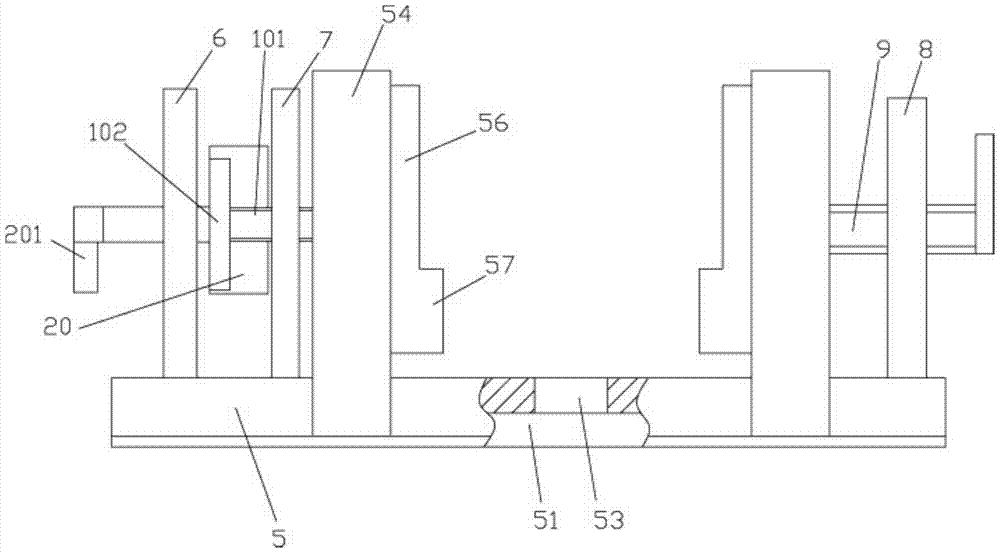

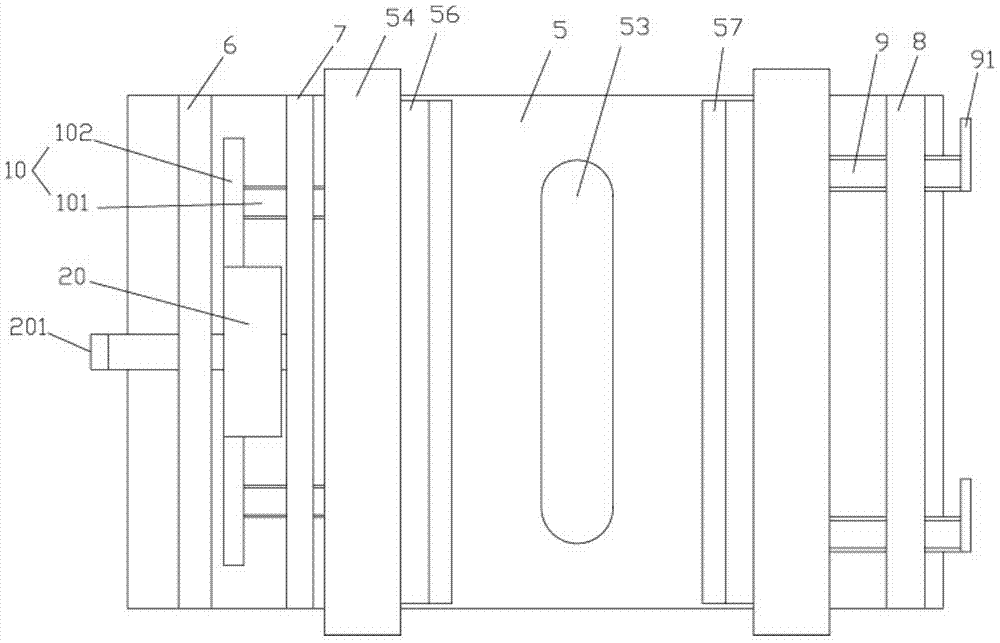

[0030] Examples, see e.g. Figures 1 to 5 As shown, a workpiece clamping device for a machine tool track includes a chassis 1 and a longitudinal adjustment chassis 5, the bottom surface of the chassis 1 has a longitudinal moving groove 11, and an adjustment screw hole 12 is formed on the side wall of the chassis 1. The locking bolt 2 is screwed in the adjusting screw hole 12, and the two locking nuts 21 are screwed in the screw rod of the locking bolt 2. At least two horizontal adjusting rails 13 are fixed on the top surface of the chassis 1. The adjusting rails 13 There are bar-shaped protrusions 131 formed on the left and right side walls of the upper and lower sides, and the bottom of the upper cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com