Automatic pavement cleaner for leveling road surfaces

A technology of stickies and cleaners, applied in road cleaning, cleaning methods, construction, etc., can solve the problem that chewing gum cannot be completely removed, and achieve the effect of ensuring the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

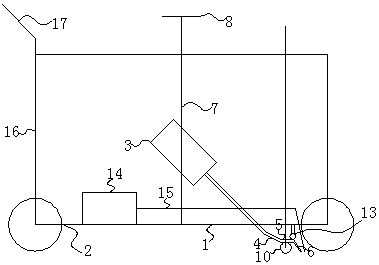

[0018] The present invention will be further described below in conjunction with the drawings.

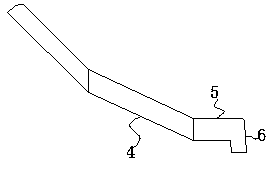

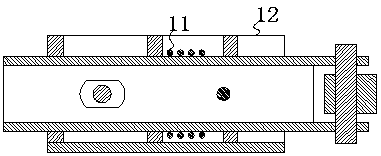

[0019] Such as Figure 1-3 As shown, an automatic road surface adhesion cleaner for leveling road surfaces includes a chassis 1 and rollers 2 fixed around the chassis. The chassis is provided with a driving device 3 that forms an angle α with the vertical plane. The driving device The power output end of the connector 4 is fixed with a roughly L-shaped tool, the tool includes a horizontal part 5 that transitions horizontally with the connector and a vertical part 6 that is perpendicular to the ground. The connector and the power output of the drive device The extension line of the end forms an angle α, the chassis is also fixedly connected with a lifting screw 7 linked with the driving device, and a turntable 8 is screwed on the top of the lifting screw.

[0020] Obviously, the inclination direction of the driving device is the same as the forward direction of the whole machine, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com