Wire-arranging mechanism of multi-head wire-rewinding machine

A wire take-up and wire-arranging technology, which is used in the transportation of filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of wire-arrangement position deviation, increase manufacturing cost, and inconsistent wire-arrangement on the take-up tray.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

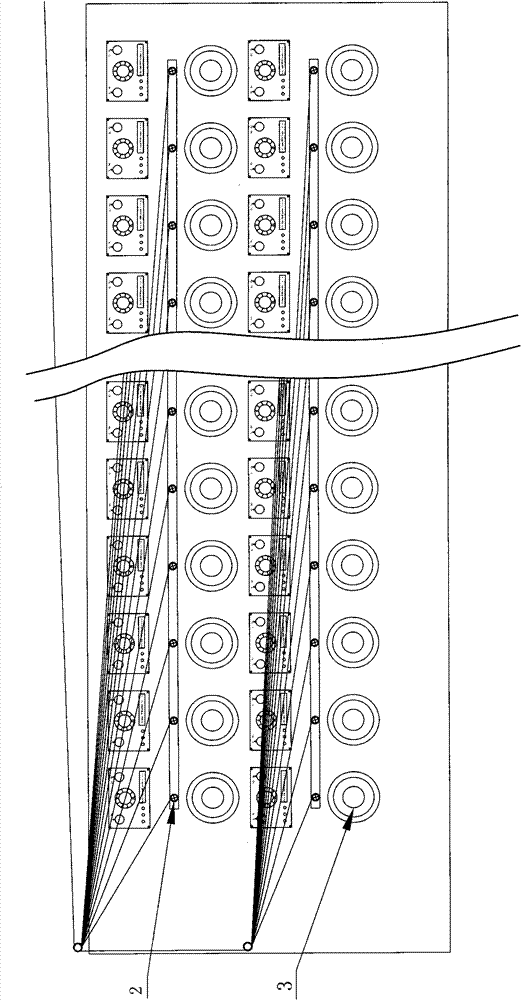

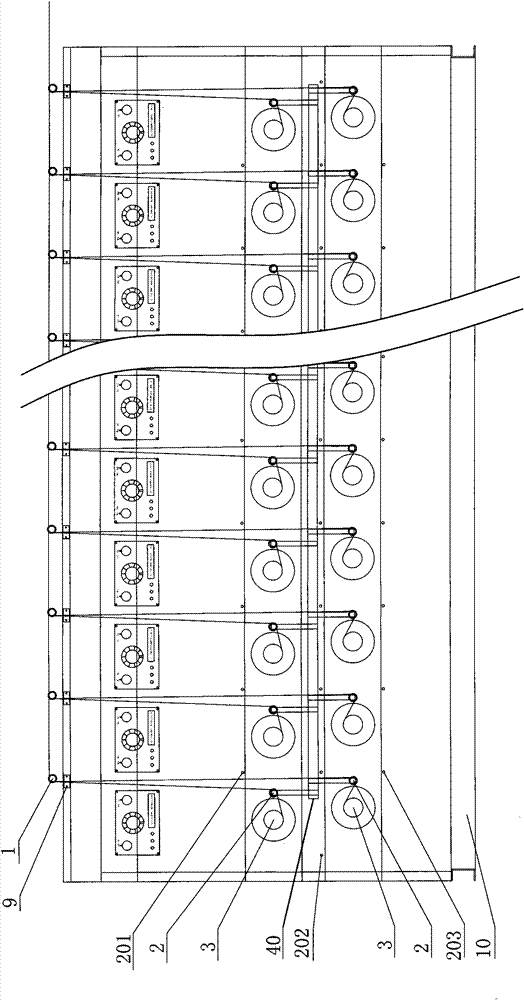

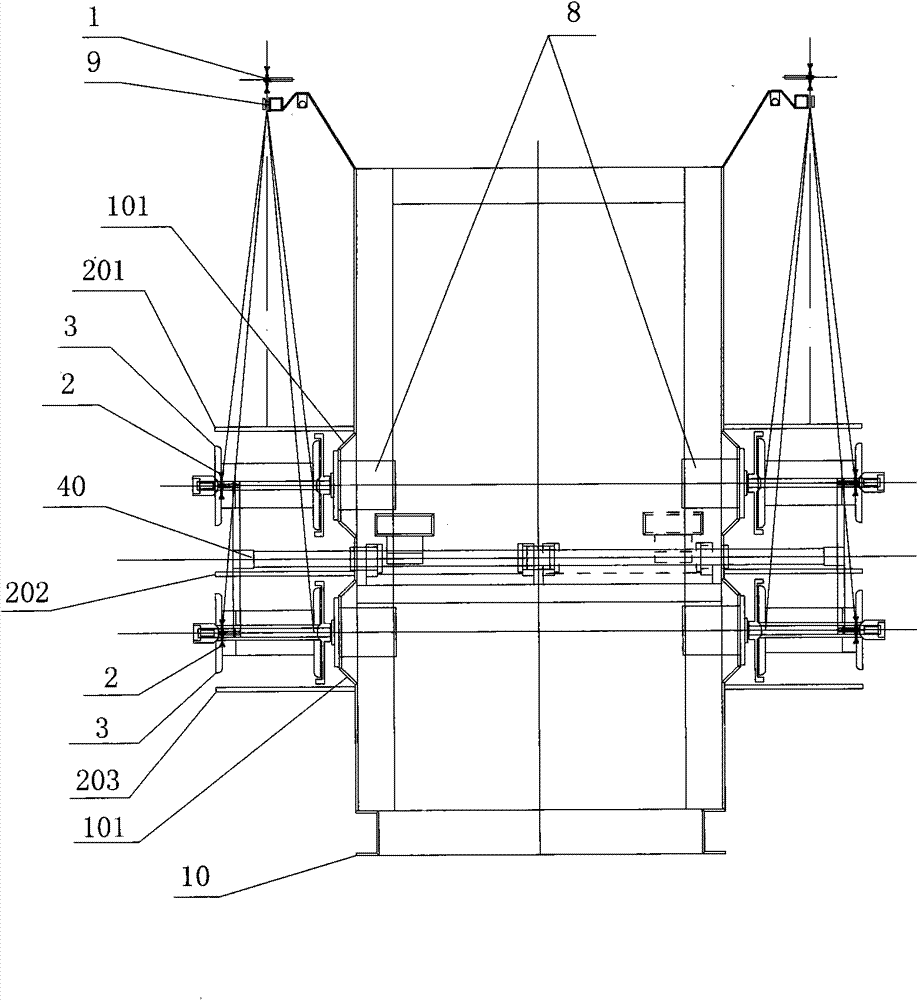

[0039] Embodiment one, such as Figures 2 to 5 As shown, a wire arrangement mechanism of a multi-head wire take-up machine, which includes a frame 10 and a PLC controller, the frame 10 is provided with at least one layer of horizontally arranged multiple take-up reels 3, each take-up reel 3 It is driven and connected by a wire take-up motor 8, and also includes a screw drive device, a wire-guiding guide wheel 2 with the same number as the wire-receiving reel 3, a reversing guide wheel 1 with the same number of production heads, and a wire-guiding guide wheel 2 for driving A reciprocating linear guide wheel driving device parallel to the axial direction of the wire take-up reel 3; The wheel 1 is correspondingly arranged above the wire take-up reel 3, and the side of each wire take-up reel 3 is correspondingly provided with a double-bearing non-sway wire guide wheel 2, and the horizontal wire rod 40 is connected to each wire guide wheel 2. The wire-guiding wheel driving device ...

Embodiment 2

[0138] Embodiment two, such as Image 6 and Figure 7 As shown, the difference from Embodiment 1 is that, in order to better ensure the parallel movement of the horizontal cable rod 40 for the cable arrangement mechanism of the multi-head wire take-up machine, the same constant speed motor 56 can be used to distribute the cables in a triangle. The belt pulley drives two sets of screw mandrel drive units, and the screw mandrel female 51 of two sets of screw mandrel drive units is connected with the cable guide wheel drive unit at two points. After the screw nut 51 is connected with the wire-guiding wheel driving device at two points and separated by a certain distance, it can more effectively limit the deflection when the wire-guiding wheel driving device moves, and ensure its parallel movement. But this will make the structure more complex, and it is not necessary to use it under normal circumstances. Image 6 As shown in , the screw nut 51 is located at the top of the close...

Embodiment 3

[0139] Embodiment three, such as Figure 8 As shown, the difference from Embodiment 1 is that the wire blocking device is a wire blocking plate 71 . Because the wire retaining rod can only prevent the finished wire rods from being injured on other wire take-up motors 8, the protection of the wire rods during the operation from the reversing guide wheel 1 to the other wire take-up reels 3 near the broken wire take-up reel 3 is not enough, and it will still happen Therefore, the third embodiment adopts the structure of U-shaped wire retaining groove 70 and wire retaining plate 71 instead of the structure of wire retaining rod. Figure 8Shown is the structure of two-layer take-up reels 3, its U-shaped wire retaining groove 70 and wire retaining plate 71 will not only damage the finished wires on other take-up reels 3, but also will not interrupt other wires running nearby. The wire rod of the take-up reel 3. The three sides of the U-shaped line retaining groove 70 are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com