A glass wool product quality on-line monitoring device

A technology for monitoring devices and cotton products, applied to measuring devices, instruments, etc., can solve problems such as unstable air pressure, influence on fiber quality, and large dimensional errors, so as to reduce measurement errors, increase telescopic range, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

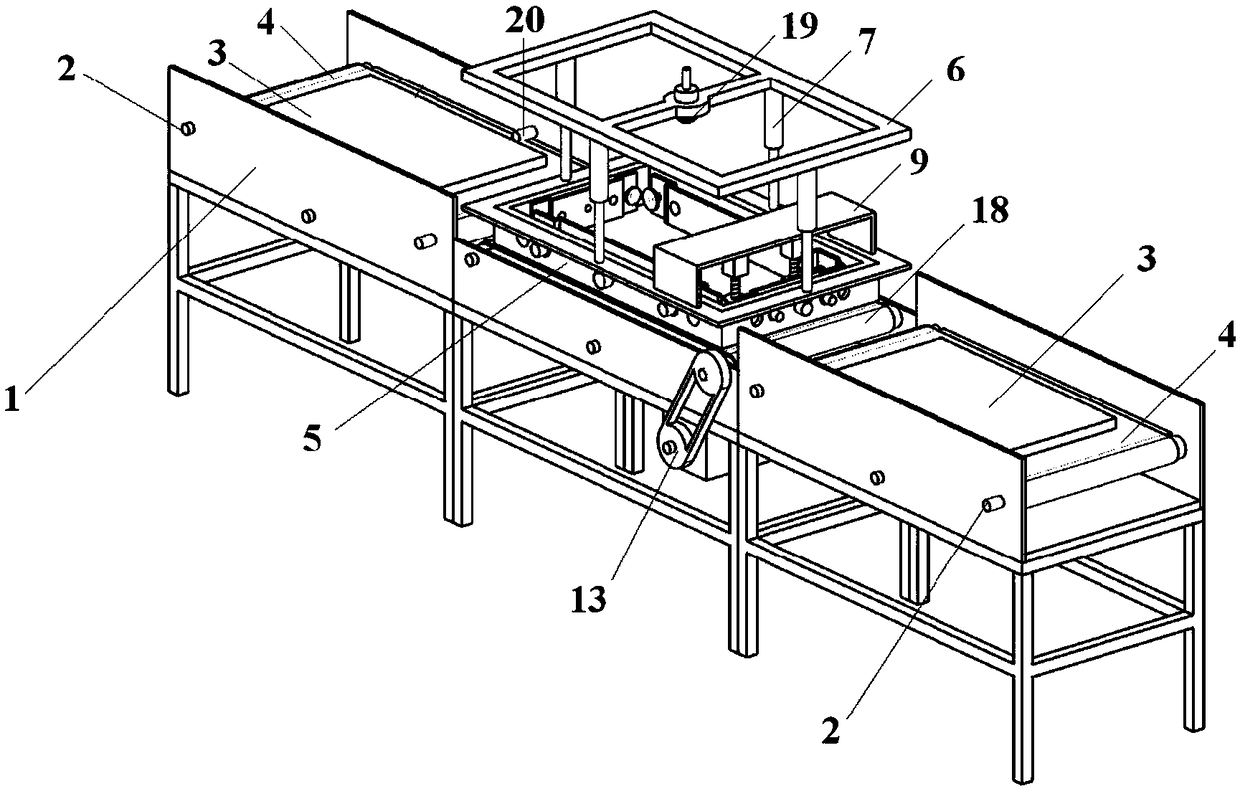

[0020] Such as figure 1 As shown, an on-line monitoring device for the quality of glass wool finished products of the present invention includes a bracket 1, a roller shaft 2 is installed between the side walls at both ends of the bracket 1, and a belt 4 for conveying glass wool 3 is arranged on the roller shaft 2. A proximity switch 20 is arranged between the side wall of the bracket 1 and the belt 4. Once the glass wool 3 breaks away from the belt and touches the proximity switch 20 during the conveying process, the entire monitoring device will stop working to prevent confusion on the production line.

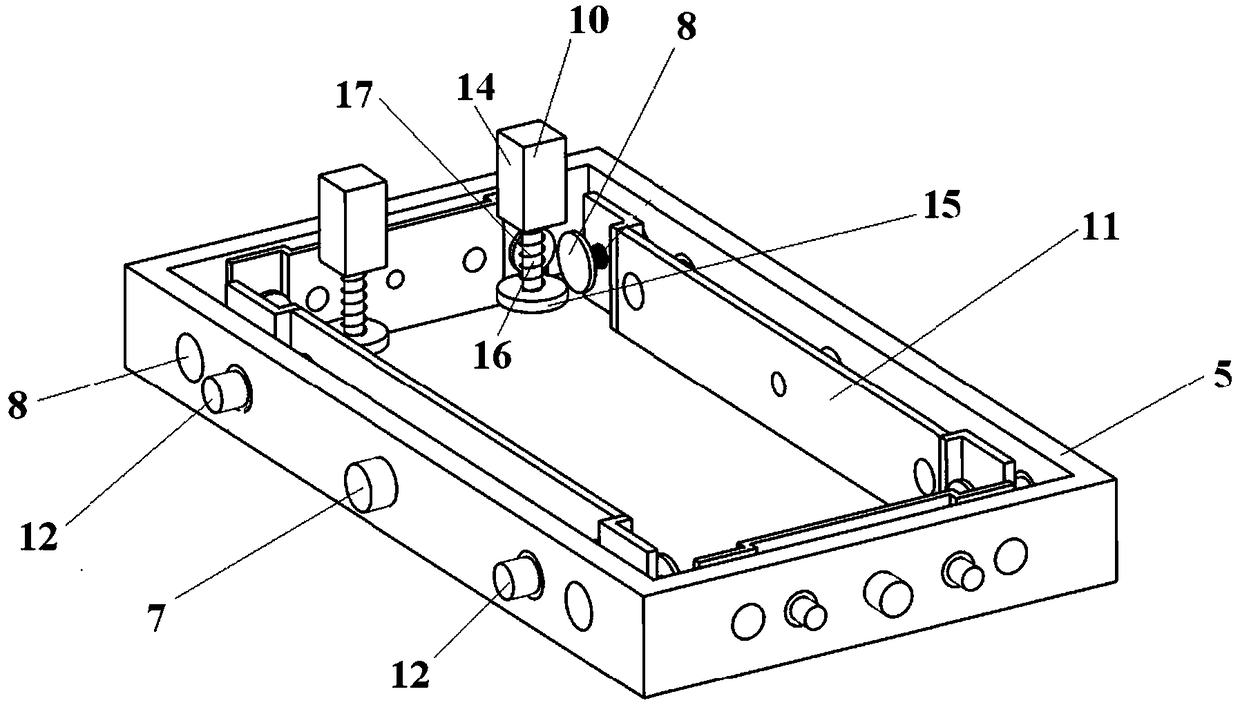

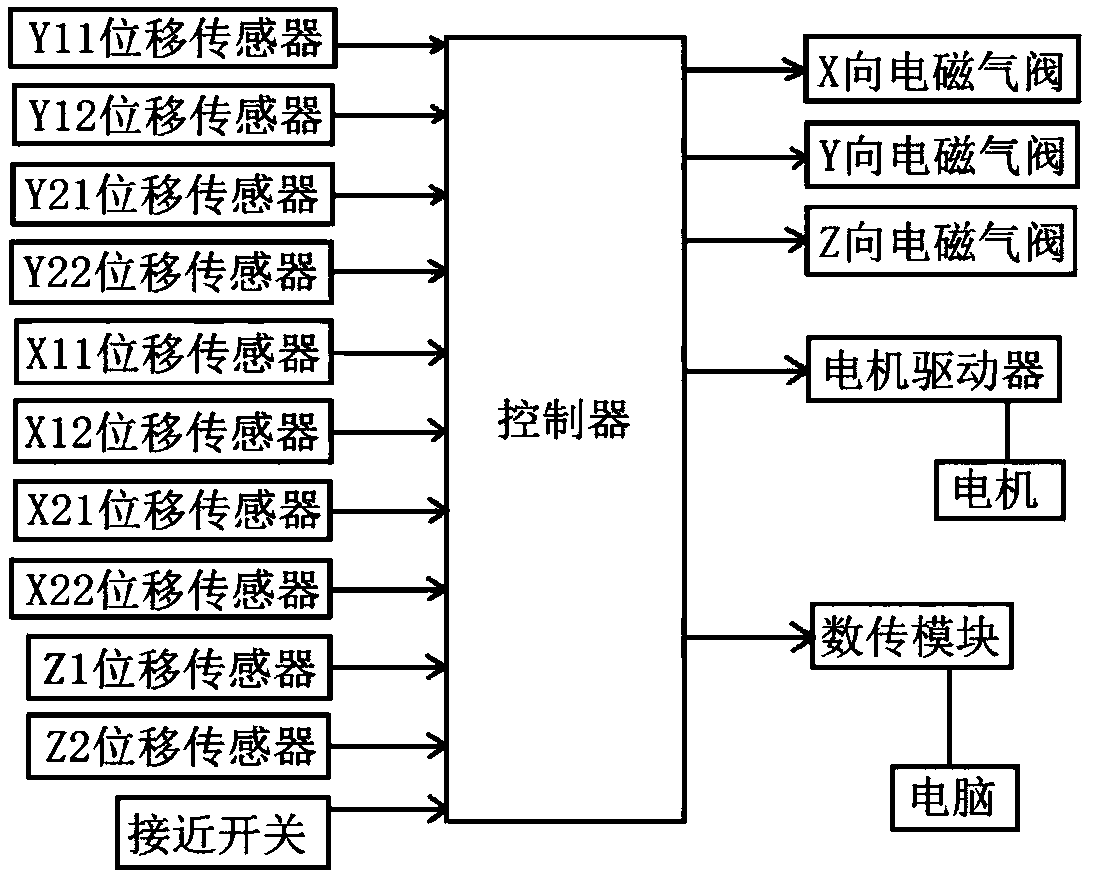

[0021] The support 1 is located between the belts 4 at its two ends and a measuring mechanism is installed. A driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com