A device and method for measuring gas pressure inside a microsphere

A technology of internal gas and microspheres, which is used in measuring devices, measuring fluid pressure, instruments, etc. It can solve the problems such as being unsuitable for measuring gases with strong adsorption, large volume errors and influences in closed spaces, and achieving a wide range of applicable gases. , the effect of a large diameter range and a wide range of gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

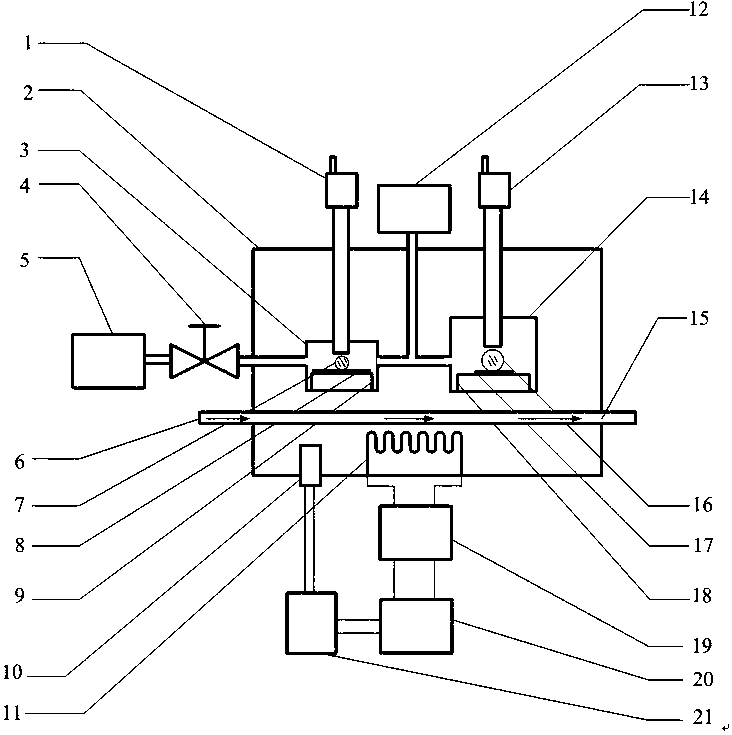

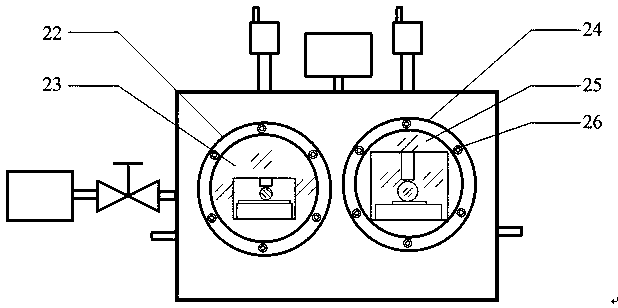

[0045] Such as Figure 1-Figure 3 As shown, the device for measuring the internal gas pressure of microspheres of the present invention includes a vacuum shell 2, a microsphere crushing mechanism 1, a calibration ball crushing mechanism 13, a vacuum pump 5, a vacuum valve 4, a vacuum gauge 12 and an adsorption gas removal device; The vacuum shell 2 is embedded with an adsorption gas removal device, the adsorption gas removal device includes a heating assembly and a cooling pipeline 6, the heating assembly heats the vacuum shell 2, and the cooling pipeline 6 cools the vacuum shell 2; the vacuum pump 5 is a molecular pump; the vacuum gauge 12 It is composed of 2 film capacitance gauges with different ranges, the ranges are 10 -4 Pa~1Pa and 1~10 4 Pa; the material of the vacuum shell 2 is 304 stainless steel.

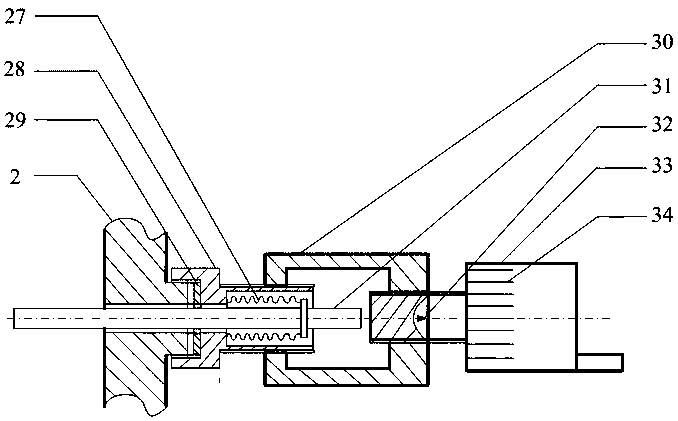

[0046] The microsphere crushing mechanism 1 and the calibration ball crushing mechanism 13 have the same structure and are placed side by side. The microsphere crushing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com