Coiling machine and method for glass reinforced plastic pipe

A glass steel pipe and winding machine technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve problems such as poor demoulding effect, and achieve the effect of reducing resistance and uniform winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Example 1 A glass pipe winding machine

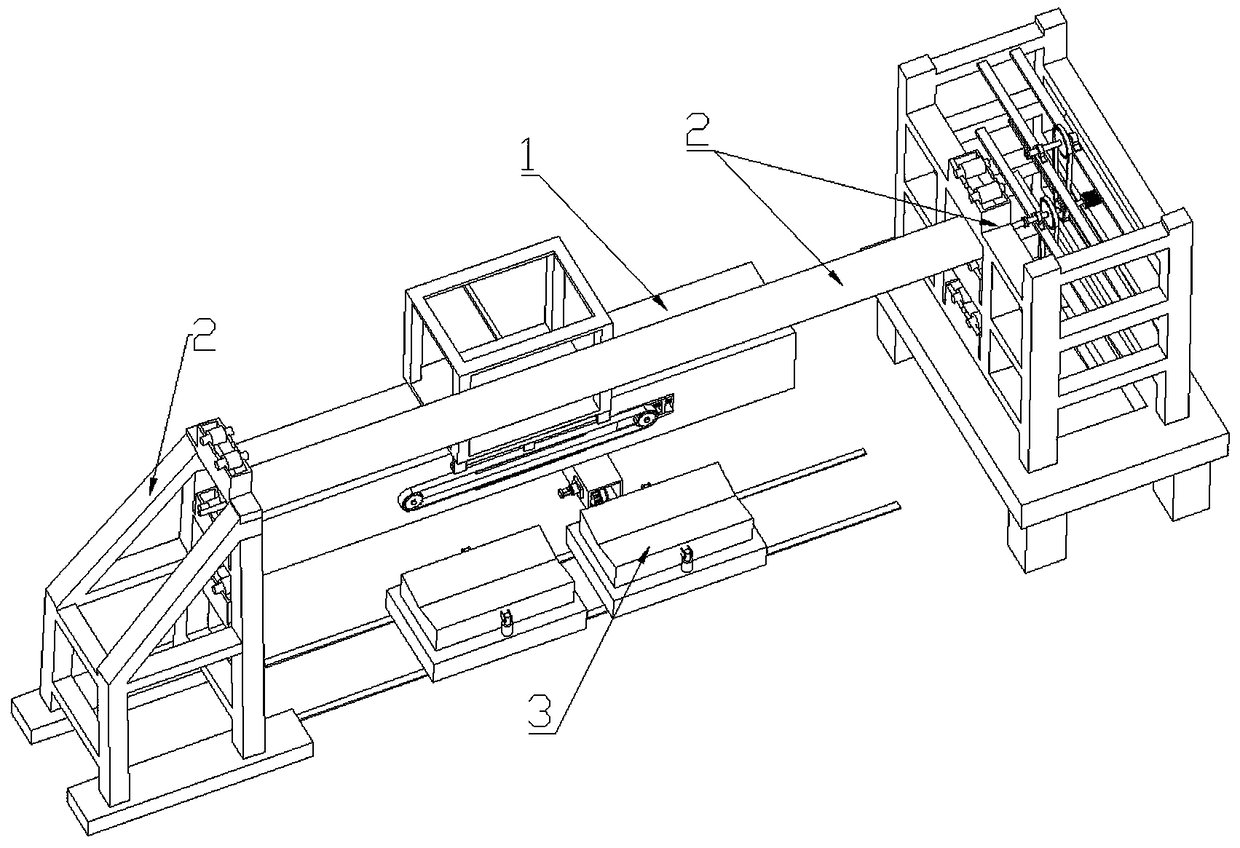

[0064] Such as figure 1 As shown, this embodiment includes a yarn unwinding device 1 , a winding device 2 and a demoulding device 3 .

[0065] 1. Yarn unwinding device 1

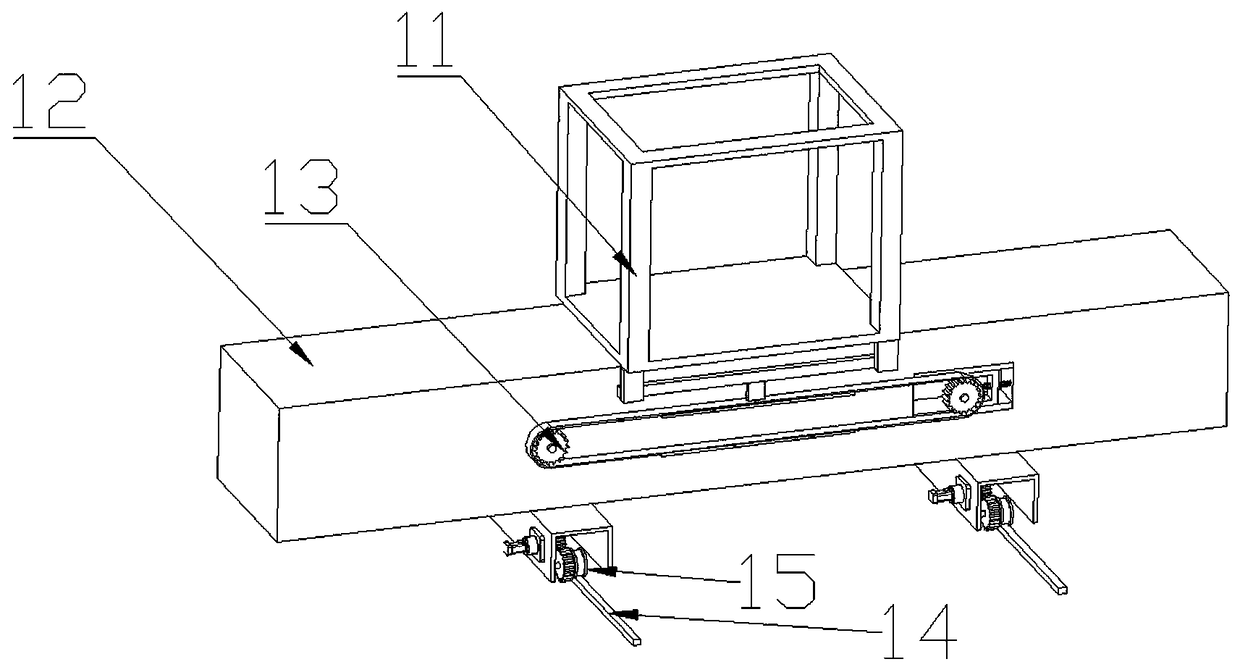

[0066] Such as figure 2 As shown, the yarn releasing device 1 includes a winding trolley 11, a winding platform 12, a yarn releasing mechanism (not shown in the figure), a longitudinal transmission mechanism 13 and a lateral movement mechanism.

[0067] The winding trolley 11 is placed on the upper part of the winding platform 12, and the two are connected through a longitudinal transmission mechanism 13. The longitudinal transmission mechanism 13 adopts the prior art, which can make the winding trolley 11 do reciprocating linear motion on the winding platform 12 along the axial direction parallel to the mandrel 23 . The longitudinal transmission mechanism 13 in this embodiment drives the driving sprocket to rotate through the motor reducer, so that the ch...

Embodiment 2

[0103] Embodiment 2 A glass pipe winding method

[0104] This embodiment utilizes the fiberglass pipe winding machine in embodiment 1 to realize, comprises the steps of following order:

[0105] A. Adjust the distance between the winding platform 12 and the mandrel 23

[0106] A0. Vertical distance adjustment

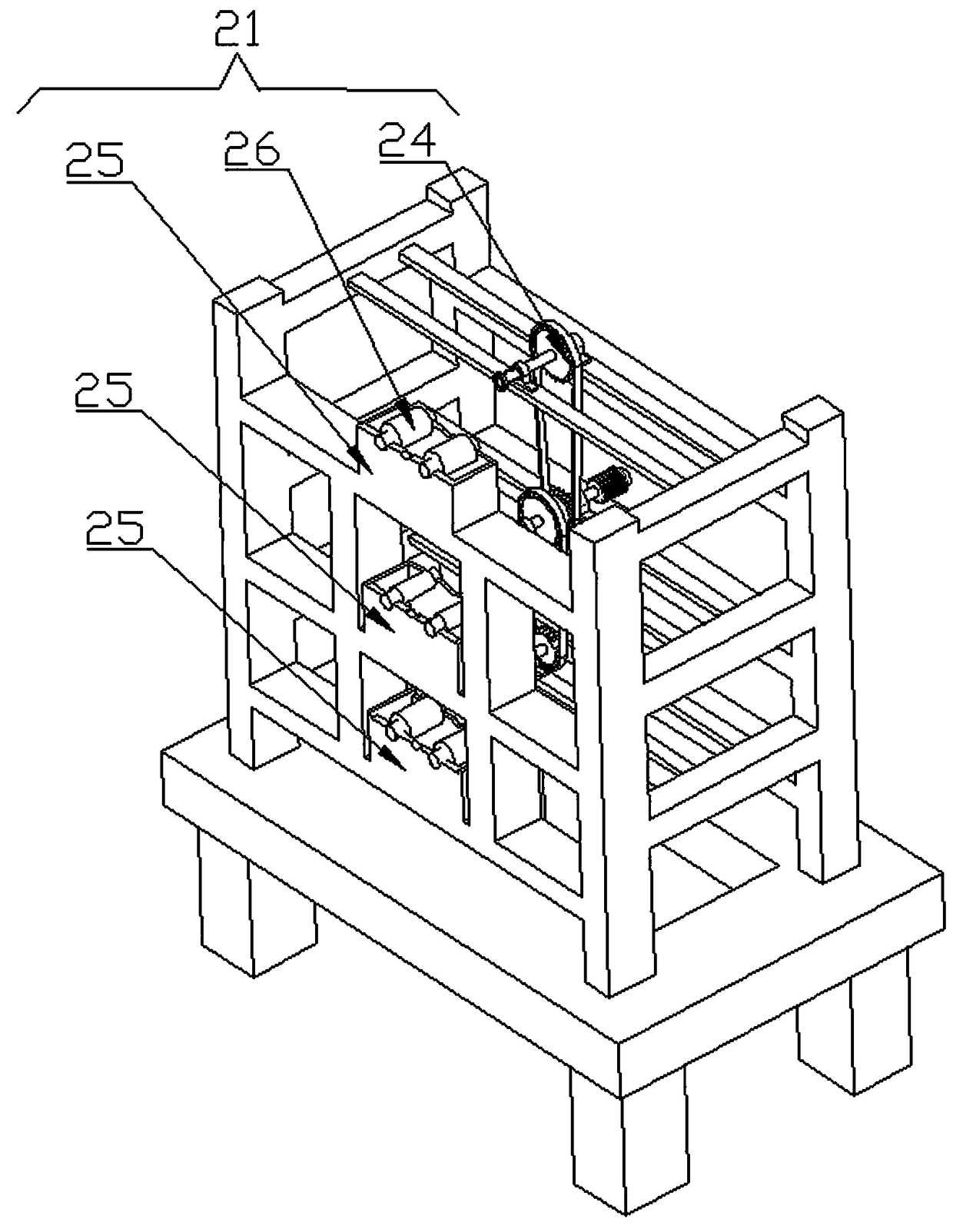

[0107] According to the diameter of the mandrel 23, the mandrel 23 is placed horizontally on the mandrel holder 25 at the optimum height of the machine head 21 and tail 22.

[0108] A1. Horizontal distance adjustment: control the winding platform 12 to move parallel to the axis perpendicular to the mandrel 23, adjust the winding platform 12 to a suitable working position and then position the winding platform 12;

[0109] B. winding

[0110] B1. The motor drives the mandrel 23 to rotate;

[0111] B2. The dipped yarn on the winding trolley 11 reciprocates along the axis parallel to the mandrel 23 from the head end of the mandrel 23 to the end of the mandrel 23, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com