Contour detection method and contour detection device for aero-engine assembly

An aero-engine and detection method technology, which is applied in the direction of mechanical measuring devices, measuring devices, and mechanical devices, etc., can solve the problems of parts and pipelines exceeding the cross-sectional range, unable to guarantee the parallel movement of the sample, and high labor intensity, so as to achieve true detection results Reliable, the measurement results are true and reliable, and the effect of eliminating human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

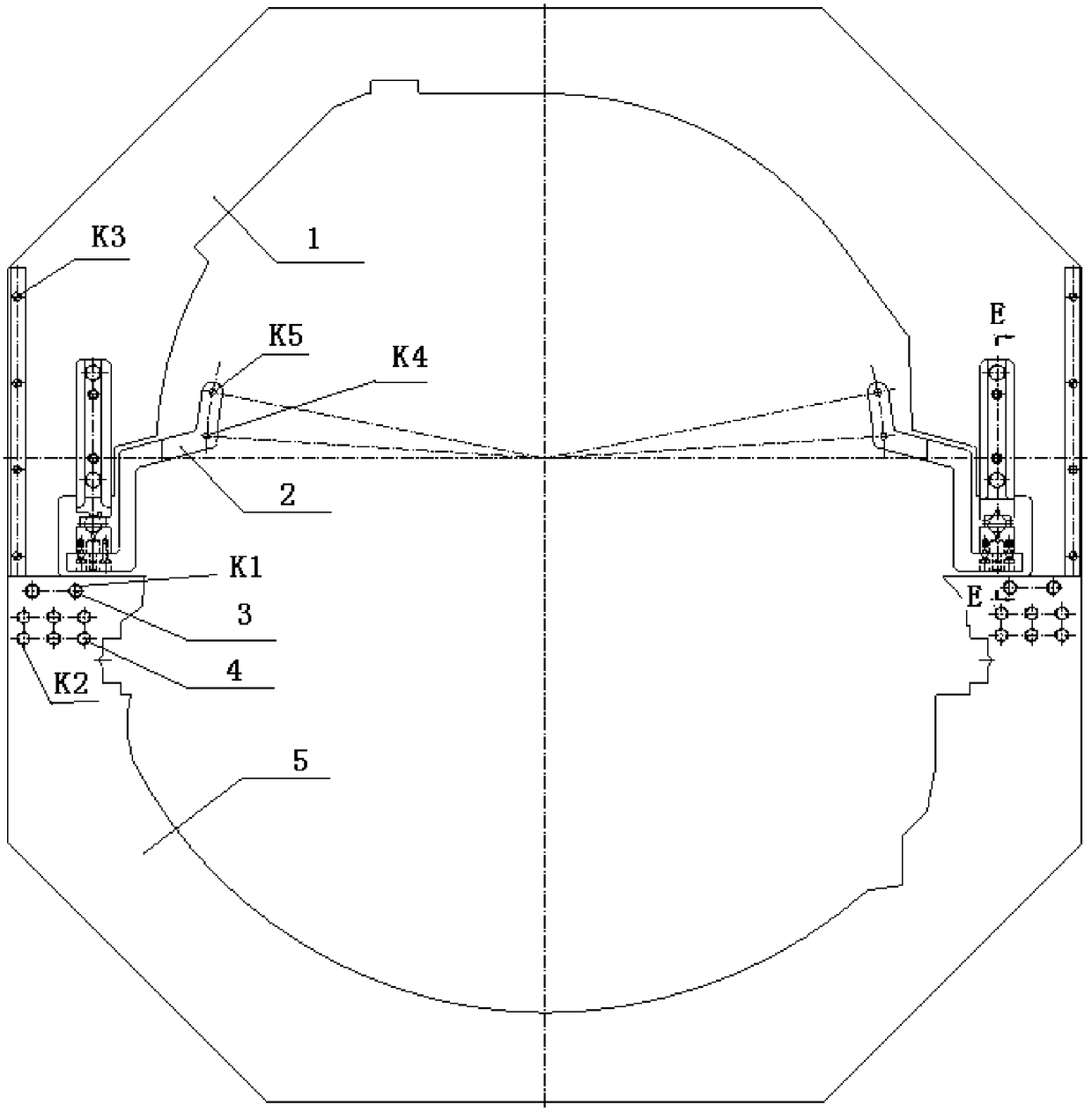

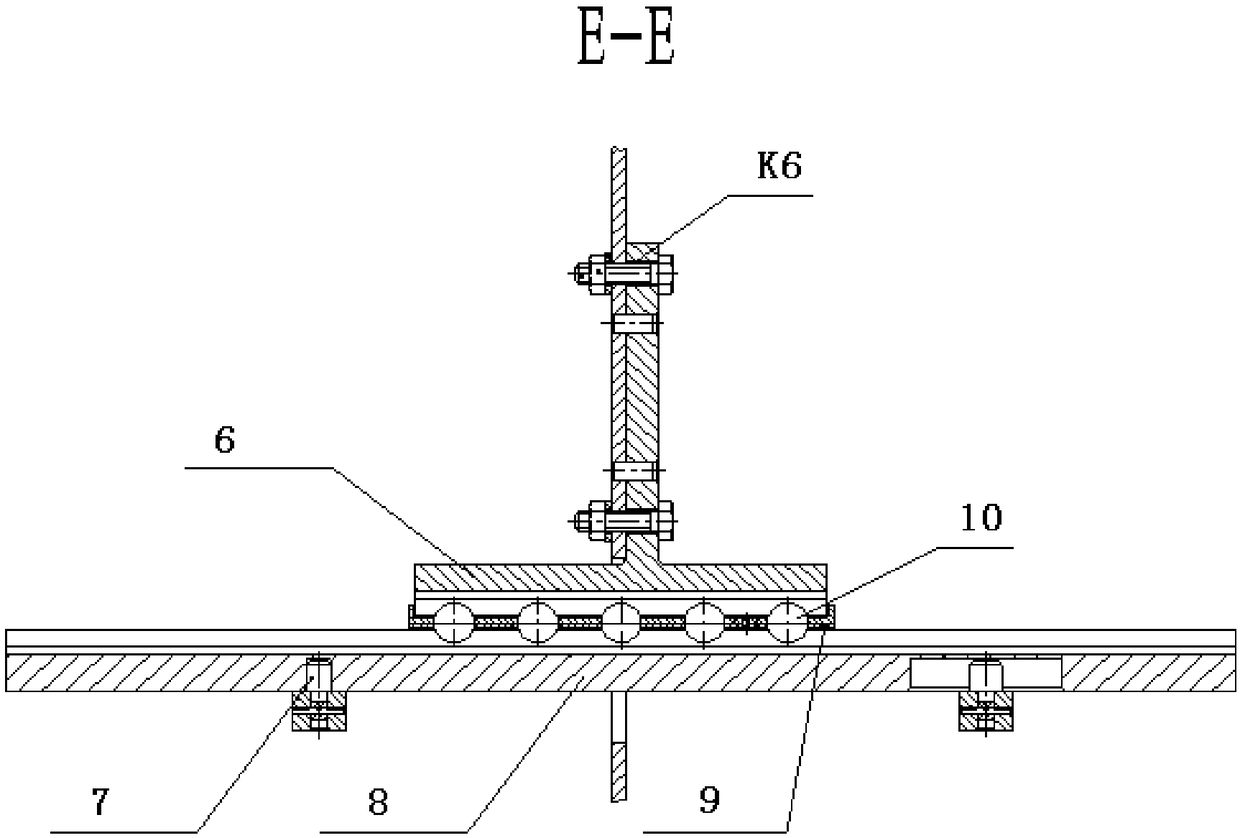

[0025] Such as figure 1 As shown, the detection device mainly consists of an upper profile template 1, a positioning bracket 2, a positioning pin 3, a bolt 4, a lower profile template 5, a slider (installed on the upper profile template) 6, and a positioning column (installed on the positioning bracket) 7 , guide rail 8, cage 9 and ball 10. The first section outline template is a whole, and the positioning pin 3 and the bolt 4 are not designed, and the use and operation steps are described below with the second section (second section). Step 1: Install the positioning bracket. Precise bolt hole positioning on the installation side of the external ducted rear receiver, the upper part of the external ducted front receiver, and the lower half of the external ducted front receiver, and a total of 4 positioning brackets with 2 fulcrums before and after installation to ensure 4 positioning The connecting line of the positioning column (front and back) on the bracket is parallel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com