Workpiece clamping device provided with rails with longitudinal moving functions for machine tool

A technology of longitudinal movement and workpiece clamping, which is applied in the direction of honing machine tools, grinding workpiece supports, manufacturing tools, etc. It can solve the problems of reducing the efficiency of adjustment, getting stuck on the slideway, and reducing the effect, so as to reduce the probability and achieve good parallelism. , to ensure the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

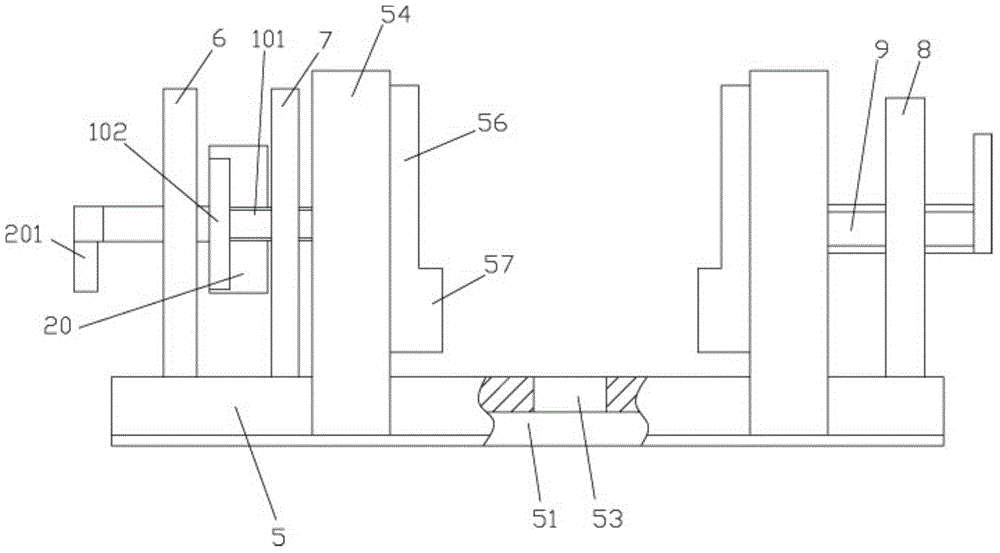

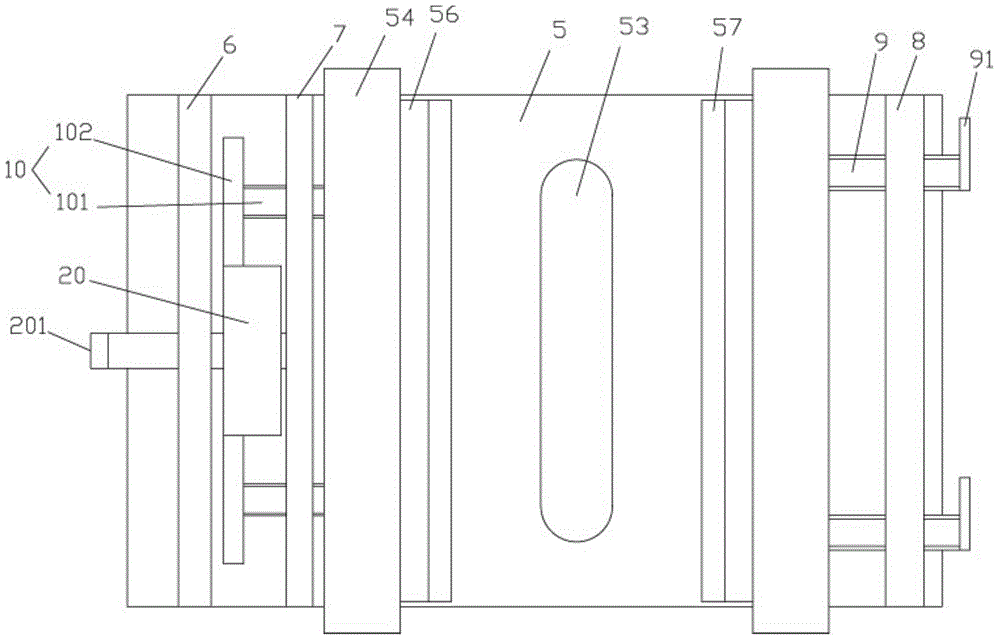

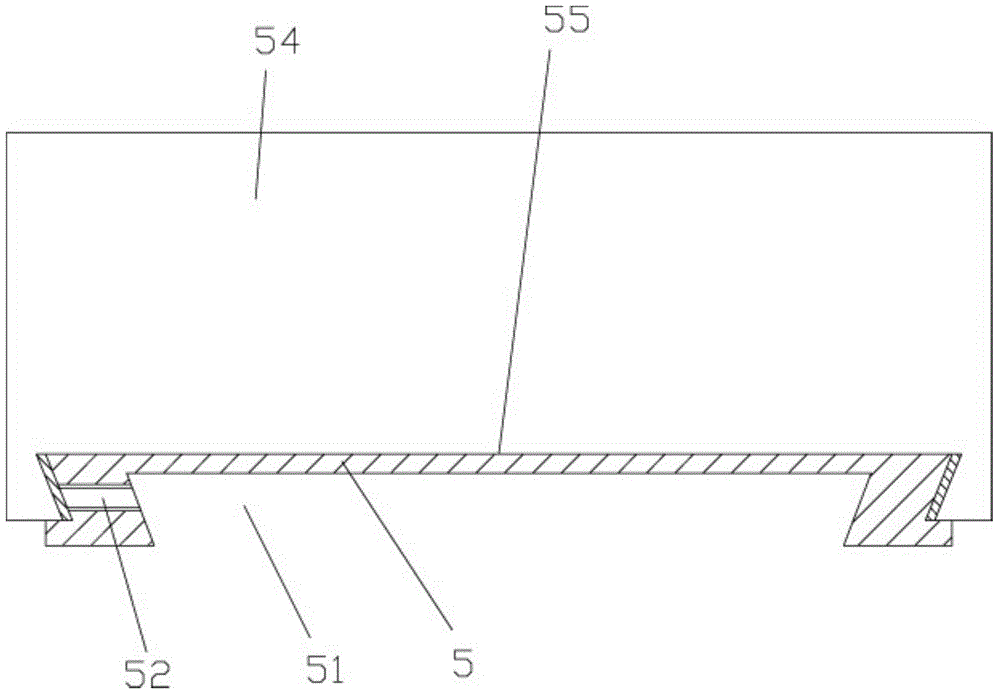

[0018] Examples, see e.g. Figures 1 to 3 As shown, a machine tool track has a workpiece clamping device for longitudinal movement, including a longitudinal adjustment chassis 5, the bottom of the longitudinal adjustment chassis 5 has a bottom chute 51, and one side wall row of the bottom chute 51 has longitudinal fixing screw holes 52. The middle part of the longitudinal adjustment chassis 5 has a waist-shaped through groove 53, and the longitudinal adjustment chassis 5 is provided with two adjustment clamping blocks 54. The bottom of the block 54 has a main groove 55, and the upper part of the longitudinal adjustment chassis 5 is inserted into the main groove 55;

[0019] The upper left side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com