Pipeline inner wall shot blasting device

A technology of shot peening device and pipeline, which is applied in the direction of abrasive feeding device, abrasive jet machine tool, abrasive, etc., and can solve problems such as difficult shot blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

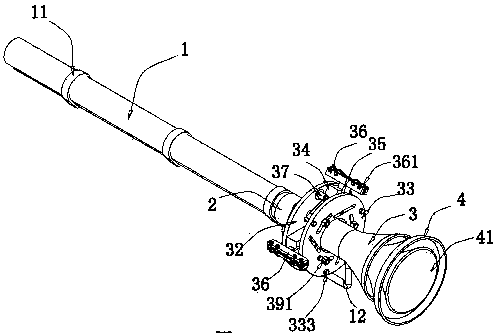

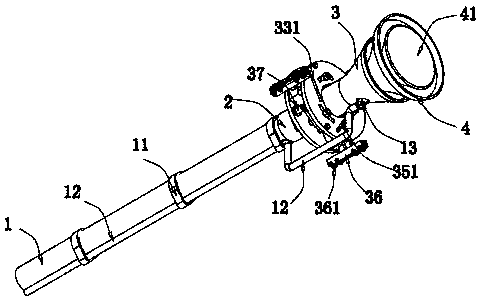

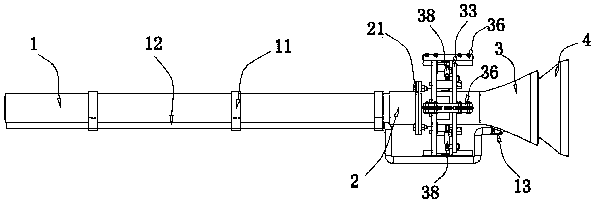

[0022] Such as Figure 1 to Figure 8 As shown, the present invention mainly includes delivery pipeline 1, high-pressure air pipe 12, nozzle 13, connecting pipe 2, separation pipeline 3, base 32, turntable 33, wheel frame 36, fixed rod 37, hydraulic cylinder 38, positioning rod 39, high pressure The air outer cylinder 4 and the high-pressure air inner cylinder 41 will be described in detail below in conjunction with the accompanying drawings.

[0023] Such as Figure 1 to Figure 5 As shown, the conveying pipeline 1 is a metal round pipe, and a connecting pipe 2 is threaded or fixedly installed at the end of the conveying pipeline, and a first flange 21 is fixed on the connecting pipe away from the conveying pipeline. A high-pressure gas pipe 12 is bound and fixed on the conveying pipeline by cable ties 11, and the high-pressure gas enters the high-pressure gas pipe, and a nozzle 13 is arranged at the end of the high-pressure gas pipe.

[0024] On the same side of the conveyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com