Automatic sharpening machine

A grinding machine and automatic technology, which is applied to the parts of grinding machine tools, grinding automatic control devices, grinding machines, etc., can solve the problems of short grinding time, non-uniformity, low efficiency, etc., and achieve a safe and environmentally friendly working environment , improve the effect of grinding and improve the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

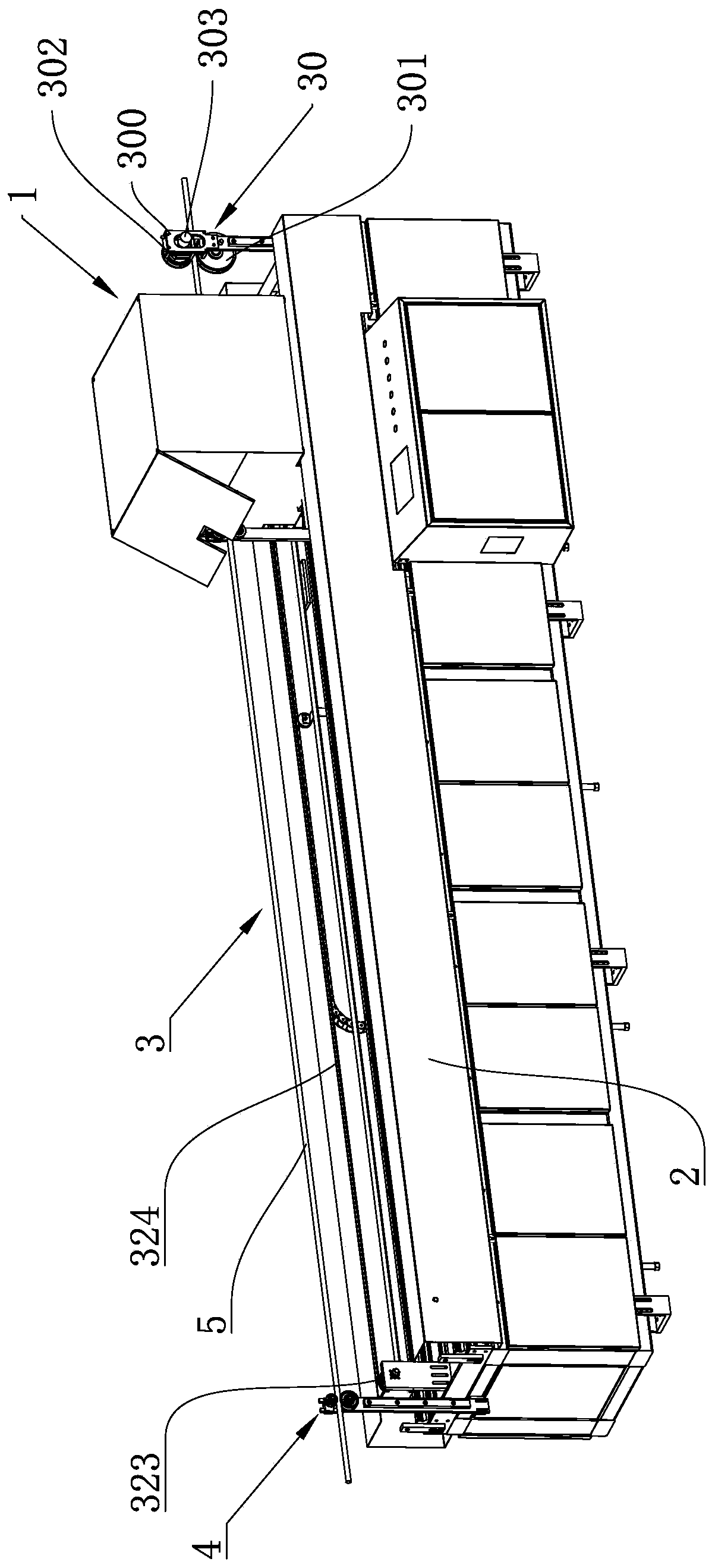

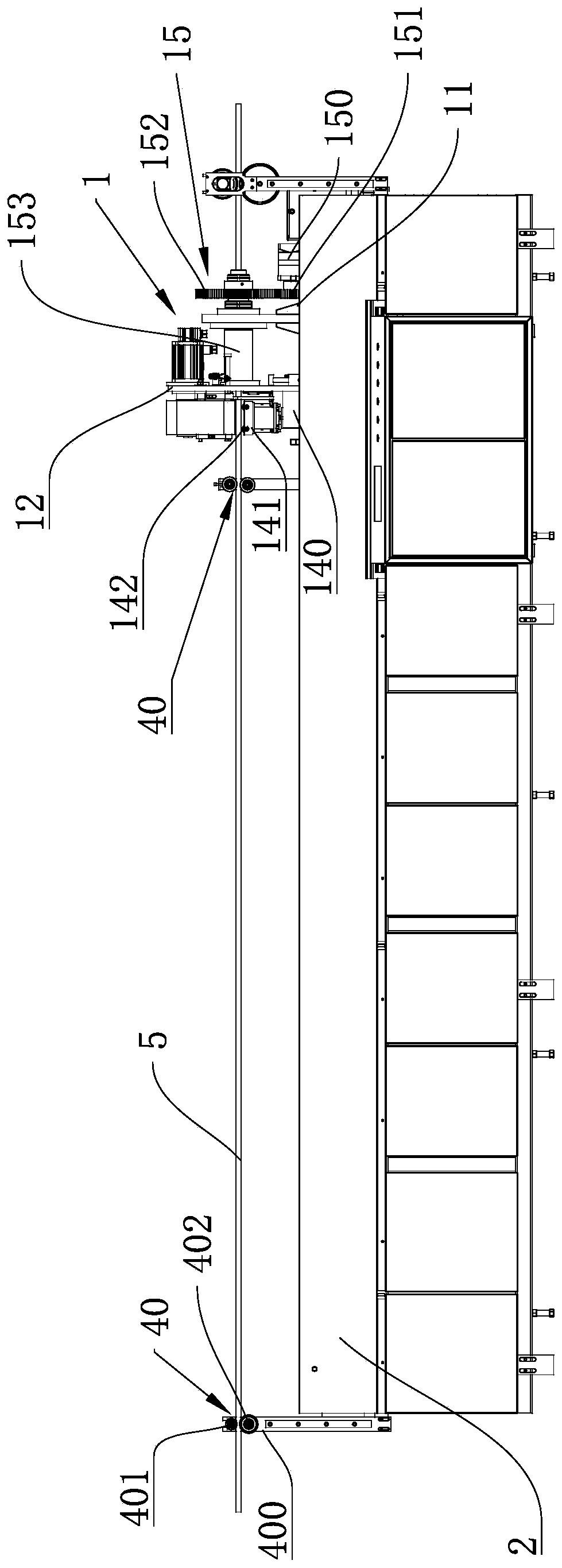

[0033] Such as figure 1 with Figure 4 As shown, the automatic grinding machine includes a grinding mechanism 1 and a platform 2. The grinding mechanism 1 can perform reciprocating linear motion along the axis of the platform 2. There is a steel wire channel 10 penetrating in the grinding mechanism 1. The steel wire channel 10 The axial direction and the moving direction of the grinding mechanism 1 are parallel to each other. The grinding mechanism 1 can move along the moving direction of the steel wire 5 to perform synchronous grinding on the steel wire 5 to realize the polishing and grinding of the steel wire 5 in the continuous processing system and improve the processing efficiency of the steel wire 5 .

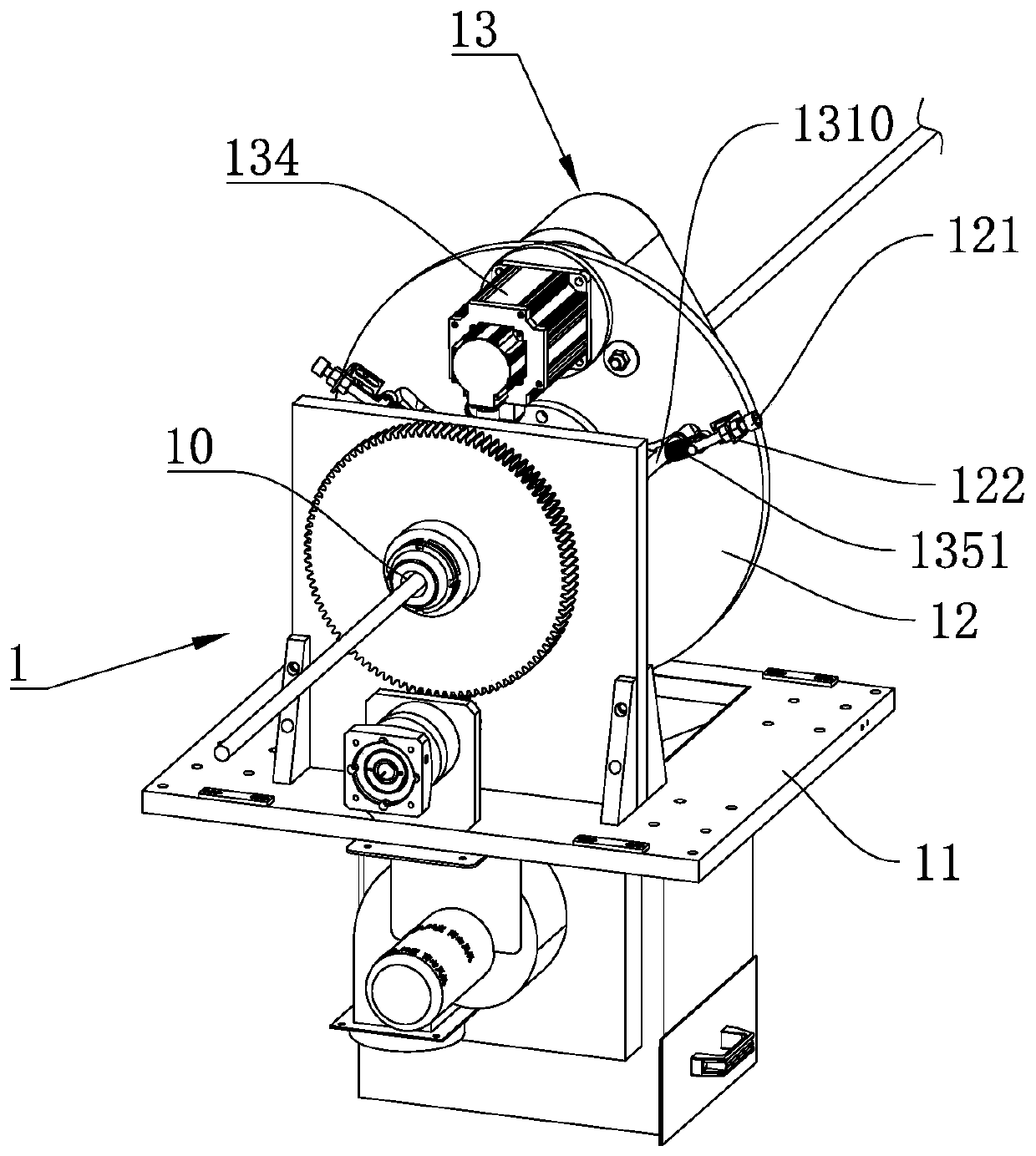

[0034] Such as figure 2 , image 3 with Figure 4 As shown, the grinding mechanism 1 includes a base 11 , a rotary table 12 , an abrasive belt device 13 and a push rod device 14 .

[0035] Specifically, the grinding mechanism 1 includes a base 11, a rotary table 12 ...

Embodiment 2

[0054] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as figure 1 with Figure 8 As shown, the synchronization mechanism 3 of this embodiment also includes a steel wire speed measuring assembly 30 for measuring the axial running speed of the steel wire. The steel wire speed measuring assembly 30 is electrically connected to a controller 31, and the controller 31 is electrically connected to the driving assembly 32 sexual connection.

[0055] Such as figure 1 , Figure 7 with Figure 8 As shown, the steel wire speed measuring assembly 30 includes a guide bracket 300 arranged on the platform 2, and rotates a positioning roller 301 and a counting roller 302 which are arranged on the guide bracket 300 and are used to support the steel wire. The counting roller 302 is located above the positioning roller 301 and positioned The axis of the roller 301 and the axis of the counting roller 302 are parallel to each other, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com