Device for detecting concrete strength by common bearing platform hoop method and detection method thereof

A technology of concrete strength and hoop method, which is used in the application of stable tension/pressure to test the strength of materials and the preparation of samples for testing. It is perpendicular to the axis, avoids bearing lateral force, and facilitates the effect of hoop stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The device and method for detecting the strength of concrete by the common platform hoop method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

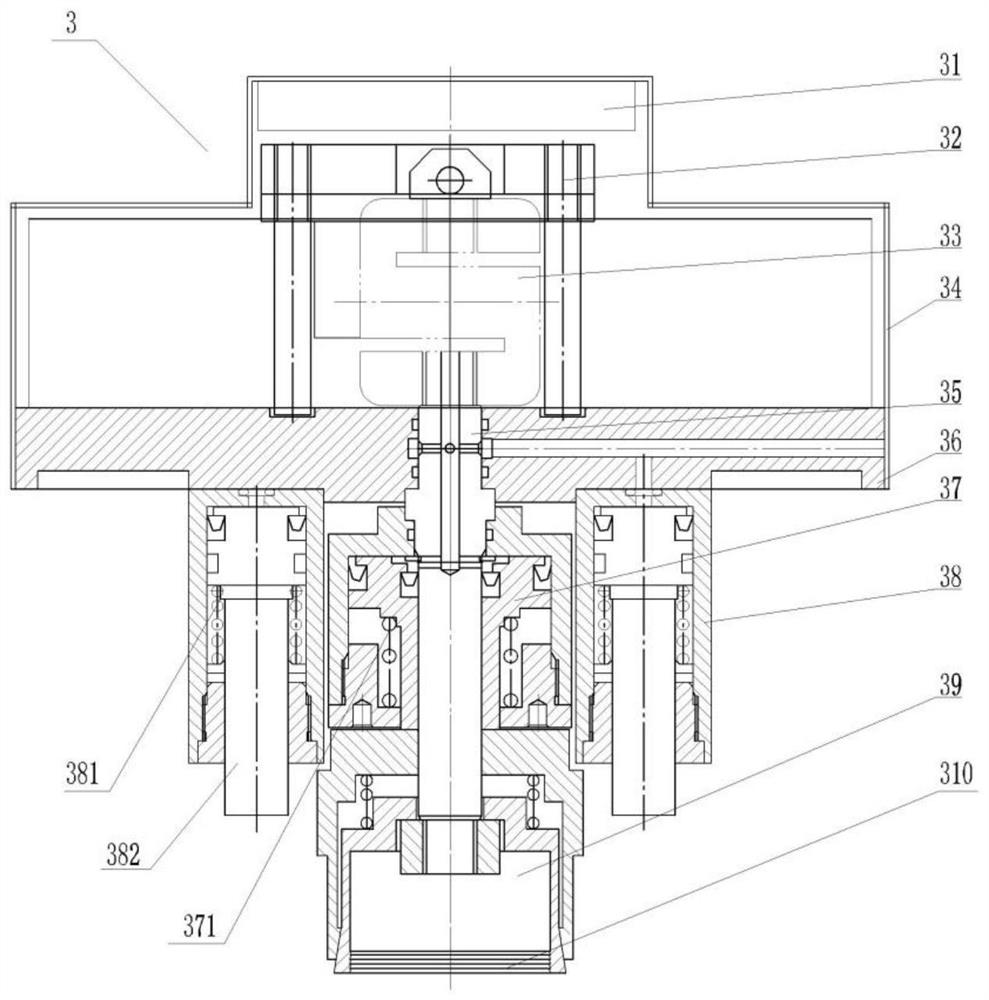

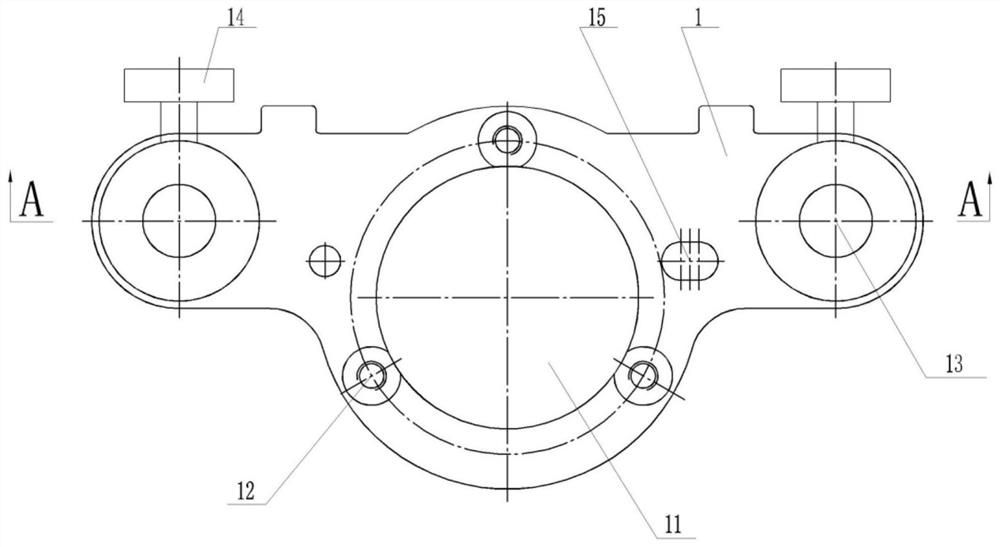

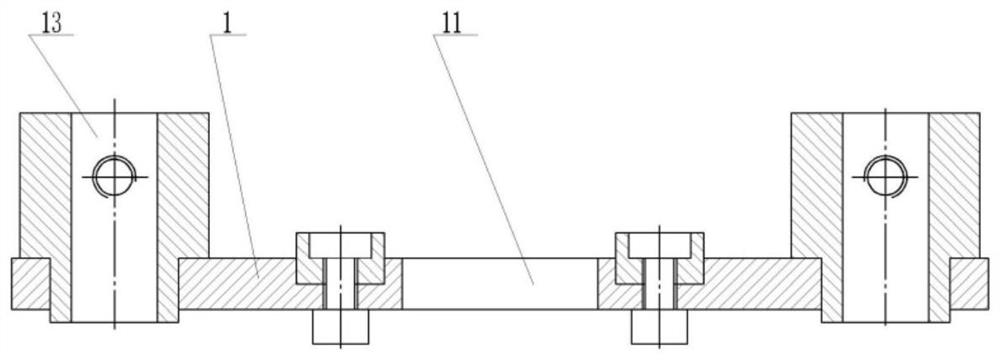

[0047] Such as Figure 1 to Figure 9 As shown, the device for detecting concrete strength by the common platform hoop method of the present invention is composed of a reference plate 1, an automatic drilling and milling machine 2, and an automatic in-situ hooping instrument 3; the automatic drilling and milling machine 2 and the automatic in-situ hooping instrument 3 alternately fixed on the reference plate 1;

[0048] Such as Figure 2-3 As shown, the reference plate 1 is made of steel plate as a whole, the reference plate 1 is a T-shaped structure, a circular through hole 11 is arranged in the middle of the reference plate 1, and three positioning sleeves 12 are arranged around the circular through hole 11, and the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com